Blending silky single jersey cloth of polyester fiber and modal fiber and preparation method thereof

A modal fiber and polyester fiber technology, applied in the textile industry, can solve problems such as stuffy heat and airtightness, high cost of clothing, poor comfort, etc., and achieve the effect of good drape, bright color and crisp fabric.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

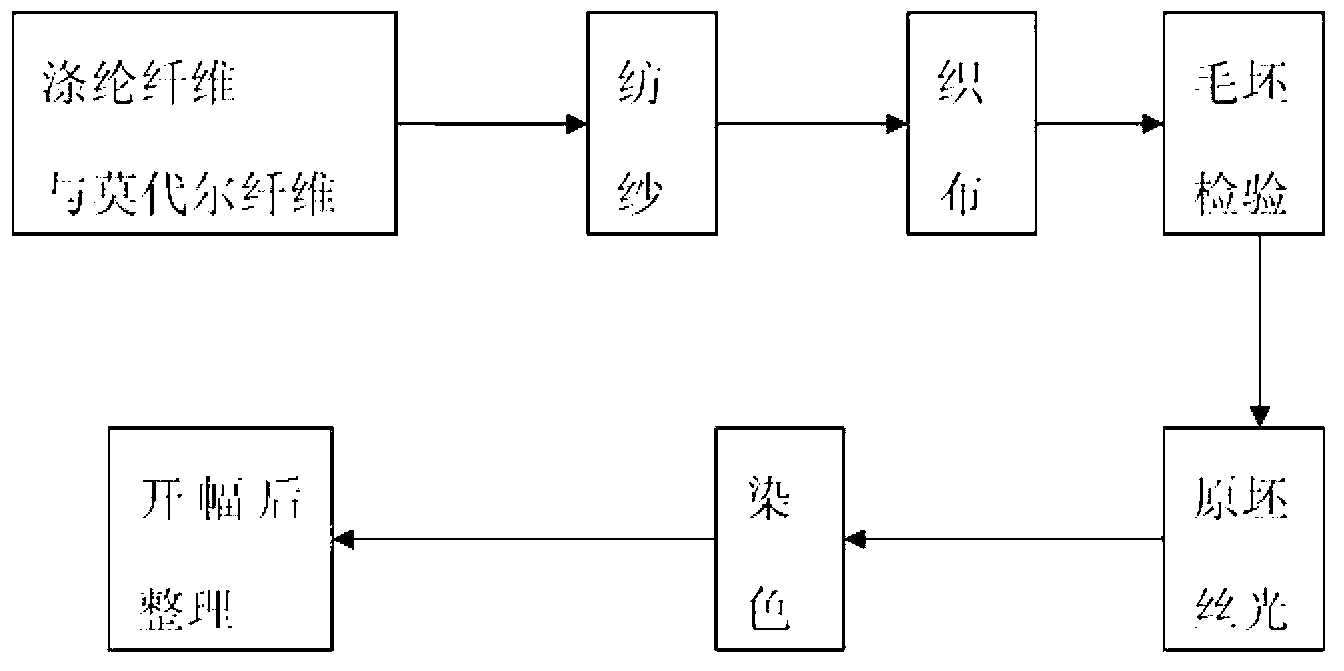

[0038] Such as figure 1 Shown: a kind of preparation method of common polyester fiber and modal fiber blended mercerized jersey fabric, comprises the following steps:

[0039] (1) Spinning: According to the weight percentage, 55-75% of polyester fiber and 25-45% of modal fiber are blended into yarn;

[0040] (2) Weaving: use a knitting machine to weave the yarn obtained in step (1) into a single-sided jersey, the weight of the single-sided jersey is 140 grams, and the length of the weaving line: 24.3CM / 100G;

[0041] (3) Blank inspection: Check whether there is oil and holes on the single-sided cloth surface. If there is too much oil, remove the oil first and then mercerize. Check out the holes and sew them up to prevent cloth scraping during the mercerizing process;

[0042] (4) Original body mercerizing: perform mercerizing treatment on single jersey, the conditions of the mercerizing treatment are: caustic soda concentration 220-240g / l, mercerizing penetrant 2-3g / l, lye te...

Embodiment 1

[0046] A kind of preparation method of common polyester fiber and modal fiber blended mercerized jersey fabric, comprises the following steps:

[0047] (1) Spinning: According to the weight percentage, 55% of polyester fiber and 45% of modal fiber are blended into yarn, and the specification of the obtained yarn is: 25S;

[0048] (2) Weaving: use a knitting machine to weave the yarn obtained in step (1) into a single-sided jersey, the weight of the single-sided jersey is 140 grams, and the length of the weaving line: 24.3CM / 100G;

[0049] (3) Blank inspection: Check whether there is oil and holes on the single-sided cloth surface. If there is too much oil, remove the oil first and then mercerize. Check out the holes and sew them up to prevent cloth scraping during the mercerizing process;

[0050] (4) Original body mercerizing: Use a cylinder mercerizing machine to perform mercerizing treatment on single-sided jersey. The conditions for the mercerizing treatment are: caustic s...

Embodiment 2

[0065] A kind of preparation method of common polyester fiber and modal fiber blended mercerized jersey fabric, comprises the following steps:

[0066] (1) Spinning: According to the weight percentage, 65% of polyester fiber and 35% of modal fiber are blended into yarn, and the specification of the obtained yarn is: 30S;

[0067] (2) Weaving: use a knitting machine to weave the yarn obtained in step (1) into a single-sided jersey, the weight of the single-sided jersey is 140 grams, and the length of the weaving line: 24.3CM / 100G;

[0068] (3) Blank inspection: Check whether there is oil and holes on the single-sided cloth surface. If there is too much oil, remove the oil first and then mercerize. Check out the holes and sew them up to prevent cloth scraping during the mercerizing process;

[0069] (4) Original body mercerizing: Use a cylinder mercerizing machine to perform mercerizing treatment on single-sided jersey. The conditions for the mercerizing treatment are: caustic s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com