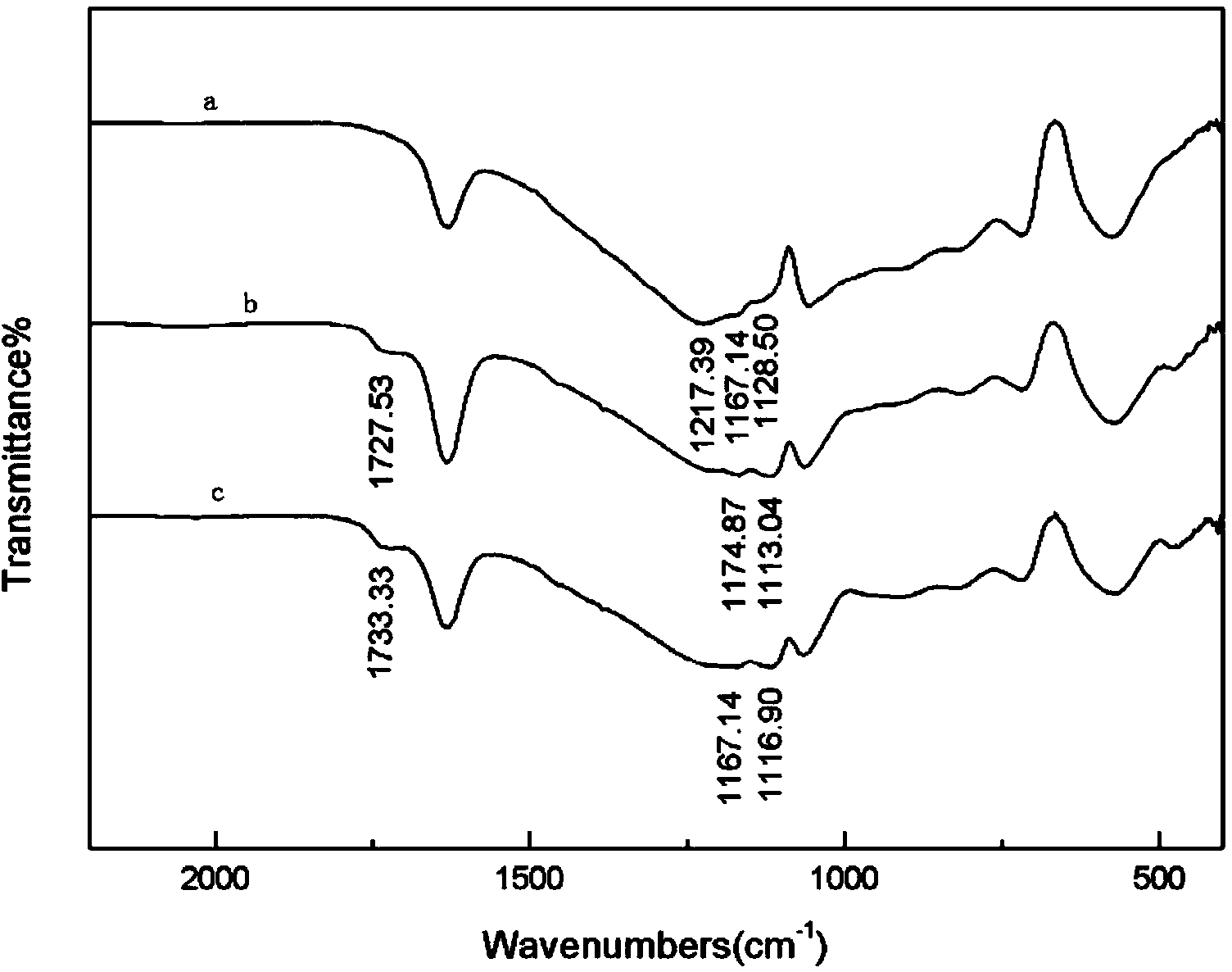

Mullite fiber surface modification method

A technology of mullite fiber and surface modification, applied in fiber processing, textile and paper making, etc., can solve the problems of adhesion, low surface energy, poor dyeing and coating effect, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The embodiment fixes the soaking time and acrylic acid content to be 90min and 10% respectively, and the mullite fiber is soaked at several temperature points of 25°C, 35°C, 50°C, 60°C, 75°C, and 85°C.

[0043] (1) Hydrolysis of coupling agent

[0044] First use acetic acid and water to prepare an acidic solution with pH=3.5 to hydrolyze the coupling agent, and then hydrolyze for half an hour under the condition of electric stirring (rotating speed 250r / min), and the solution is completely clear.

[0045] (2) Fiber infiltration and polymer grafting

[0046] Mix the remaining components of the sizing agent at the set experimental temperature, stir for 30 minutes and add the fiber sample, and reduce the speed to 150r / min to prevent foam from being stirred violently and damage to the fiber by the stirring blade.

[0047] (3) dry molding

[0048] After soaking for 90 minutes, the fibers taken out were dried in an oven at 105°C to constant weight, and then placed in a muff...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com