Borate produced by wet grinding, and use thereof

A borate and calcium borate technology, applied in the directions of borates, manufacturing tools, boron compounds, etc., can solve problems such as high cost, and achieve the effect of preventing flammability and inhibiting growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

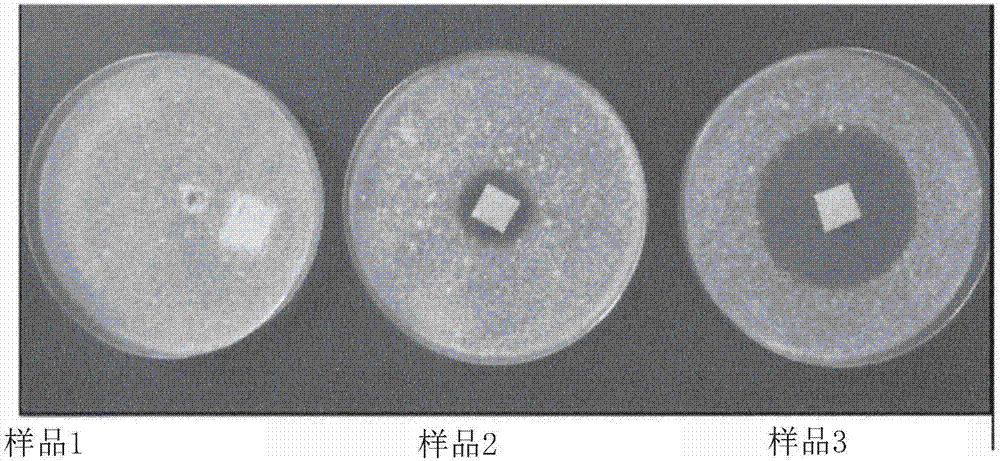

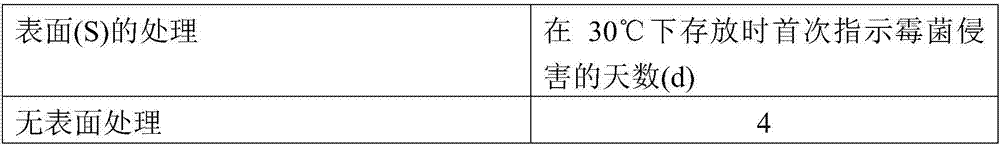

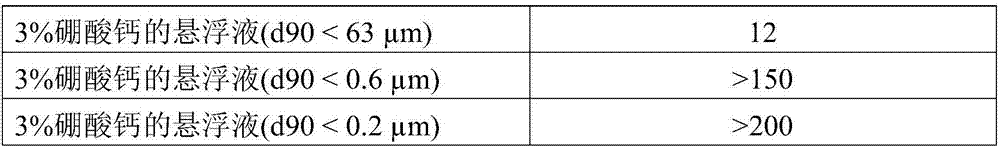

Image

Examples

Embodiment

[0081] The production of the powder according to the invention and the suspension according to the invention are described below.

[0082] The materials used are:

[0083] -Peptapon 52 (non-foaming suspension stabilizer, Zschimmer&Schwarz GmbH&Co. KG, Landstein, Germany),

[0084] -Dolapix G65 (phosphonate preparation, Zschimmer&Schwarz, Landstein, Germany),

[0085] -Tego Dispers 651 (pigment wetting and dispersing additive, Evonik Industries AG, Essen, Germany),

[0086] -Texanol (Esterol 12, Eastman Company, Kingsport, Tennessee, USA),

[0087] -Tego Airex (defoamer and deoxidizer, Evonik Industries AG, Essen, Germany),

[0088] -BYK-380N (non-ionic acrylate copolymer solution, BYK-Chemie GmbH, Wiesel, Germany).

[0089] A mixture of 80% by weight natural calcium borate, 10% by weight barium borate, and 10% by weight zirconium borate with a d90 value of about 75 μm is transferred to a conventional roller after drying at 110°C + / - 5°C In the mill, mill for 8 hours in a roller mill after...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com