Method for improving temperature gradient in high-temperature tension sample of heat expansion phase change instrument

A technique of tensile specimen and temperature gradient, applied in the direction of applying stable tension/pressure to test the strength of materials, instruments, scientific instruments, etc. Changes in tissue properties, etc., to achieve the effect of light weight, good elasticity, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

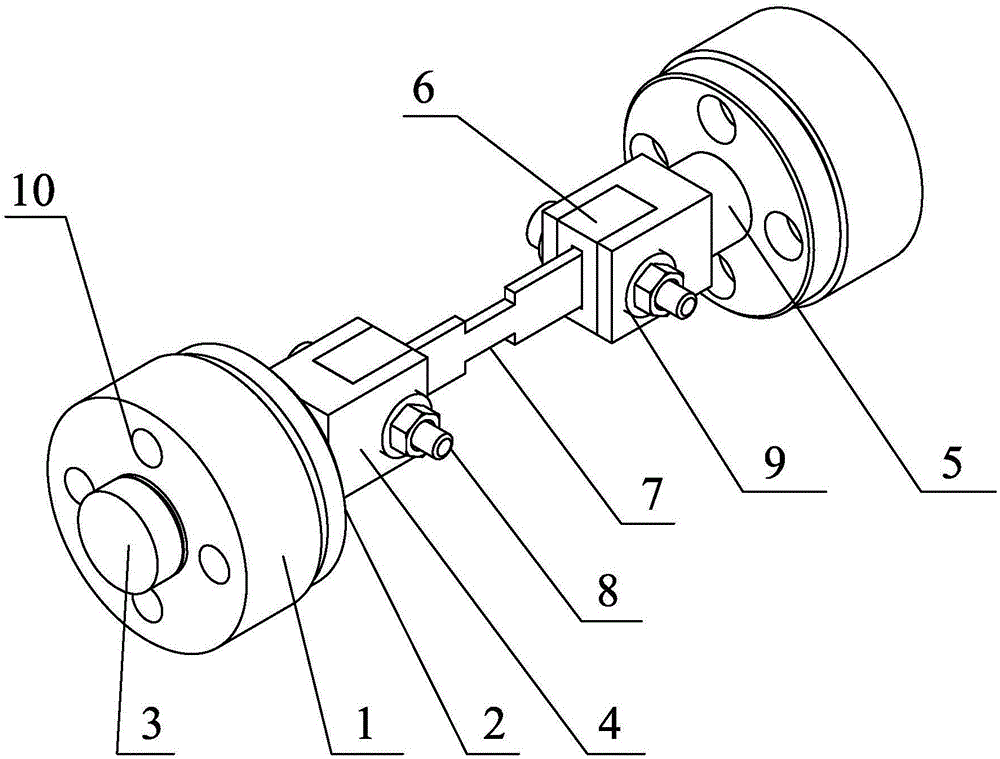

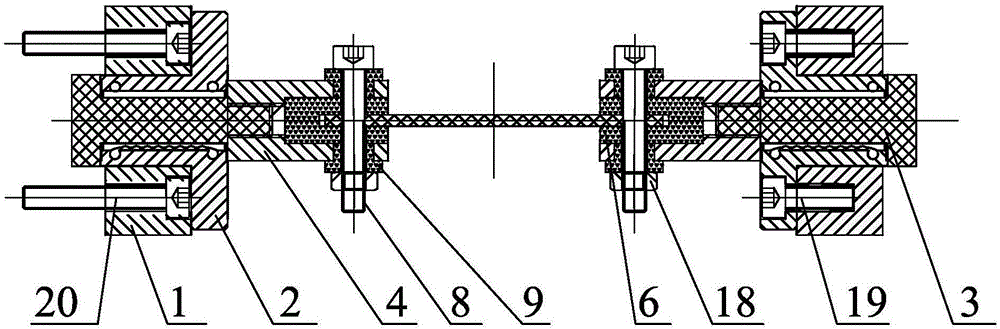

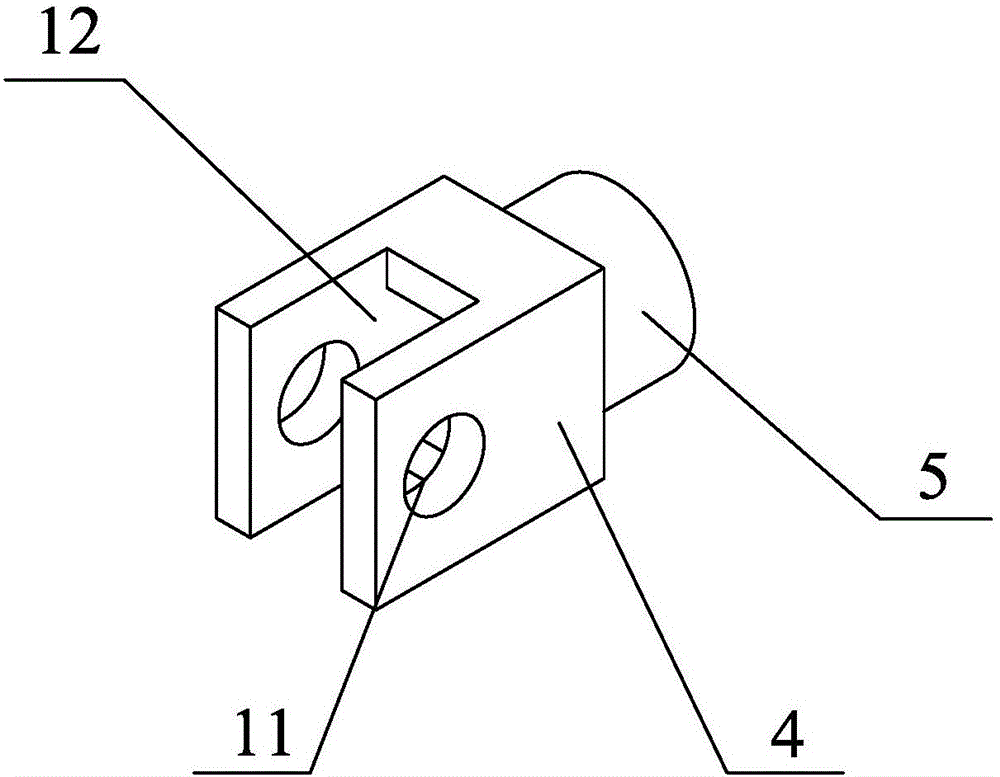

Examples

Embodiment

[0051] The model of the deformation thermal expansion phase transition instrument is DIL805A / D, the size of the tensile sample used is exactly the same as the tensile strength, the thickness of the tensile deformation zone is 2mm, and the range of the tensile strength σt (MPa) of the tensile sample is: 1000≤ σt<1667; In the actual test, the above-mentioned fixture structure is adopted, and the thickness and width of the tensile deformation zone of the sample are selected according to the actual needs of the tensile test according to the different strength ranges of the tensile sample materials. The selection method is shown in Table 1. Show.

[0052] The maximum tensile force of the DIL805A / D deformation thermal expansion phase change meter is 10kN. The main structure of the DIL805A / D deformation thermal expansion phase change meter includes a sample chamber, a displacement sensor and a ejector rod that is in direct contact with the tensile sample, and the ejector rod is a phas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

| thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com