Performance testing of anti-pressure oil well anti-seepage well cementation briquette prepared from ceramic fiber and gangue

A technology of ceramic fiber and coal gangue, which is applied in the field of performance testing of oil well anti-seepage water cementing test blocks prepared by materials and pressure-resistant ceramic fiber coal gangue, which can solve the problems of high water loss, poor impact resistance, and poor toughness of test blocks etc. to improve pore flow resistance and reduce permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

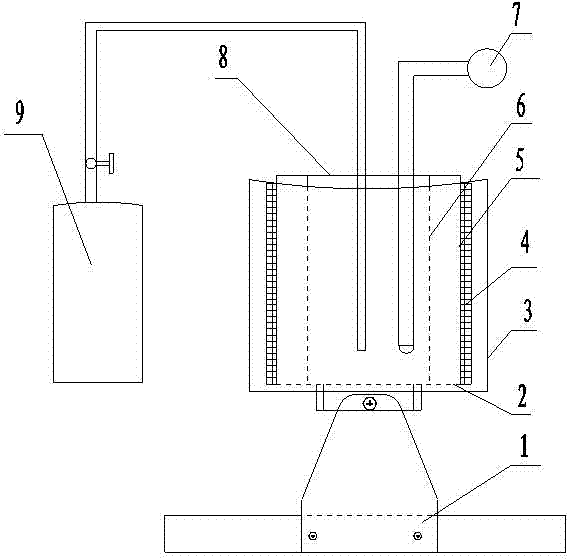

[0023] The performance test of oil well anti-seepage water cementing test block prepared by anti-compressive ceramic fiber coal gangue includes the following steps:

[0024] Step 1: Preparation of coal gangue closed-cell hollow ceramic microbeads: First, the coal gangue is crushed into small particles of 1000µm by a jaw crusher, and then 80µm spherical solid particles are made through Raymond milling, and the spherical solid particles are passed through the lifting The machine enters the dispenser, and then enters the expansion furnace from the dispenser. After expansion at 820°C, firing at 1200°C, and cooling, coal gangue ore closed-cell hollow ceramic beads with a wall thickness of 80µm and a particle size of 300µm are formed.

[0025] The second step, the ingredients of the anti-seepage water cementing test block: 43wt% of G grade oil well cement, 15wt% of ultra-fine cement, 25wt% of closed-cell hollow ceramic microbeads of coal gangue ore with a particle size of 300μm, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com