High-temperature insulation sealing strip

A high-temperature insulation and sealing strip technology, which is applied to the sealing of engines, engine components, mechanical equipment, etc., can solve problems such as high operating costs, short service life, and increased metallurgical work intensity, achieving low cost and good thermal stability , a wide range of effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0009] The present invention will be further described below in conjunction with the drawings and embodiments.

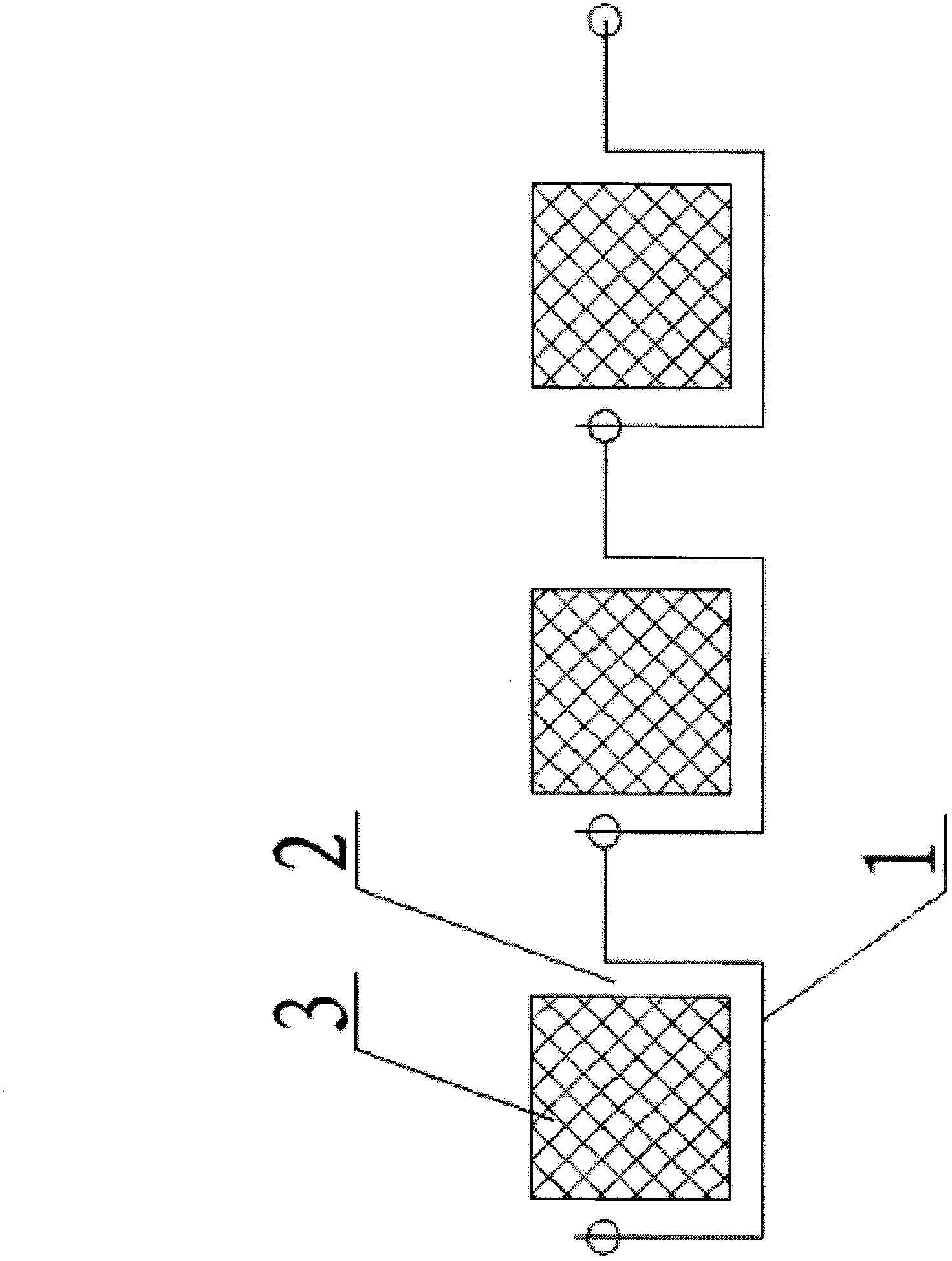

[0010] figure 1 As shown, a high-temperature insulation sealing strip includes multiple sections of insulated chains 1 with bayonet 2 and multiple segments of ceramic fiber blocks 3. The multiple sections of insulated chains 1 are hingedly connected end to end, and the bayonet 2 of each insulated chain is clamped There is a ceramic fiber block 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com