Melt-blow fireproof composite fiber non-woven fabric and preparation method thereof

A composite fiber and fireproof fiber technology, applied in chemical instruments and methods, non-woven fabrics, textiles and papermaking, etc., can solve the problems of potential safety hazards and poor fireproof performance, and achieve excellent fireproof performance, excellent weather resistance, and high insulation performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0029] As a preference, the present invention also discloses a method for preparing the above-mentioned melt-blown fireproof composite fiber non-woven fabric, the steps are as follows:

[0030] (1), the plant fibers and fireproof fibers have been opened at least twice;

[0031] (2), the plant fibers and fireproof fibers after opening are then laid by a web-laying machine and carded by a carding machine;

[0032] (3) Carry out hot air bonding, and then spray the bonded fibers to the receiving device with high-speed horizontal and low-speed longitudinal movement and form fiber cloth through air cooling;

[0033] (4) Unfold the prepared fiber cloth, and use a calender to evenly calender the silicone rubber on the fiber cloth to prepare the product.

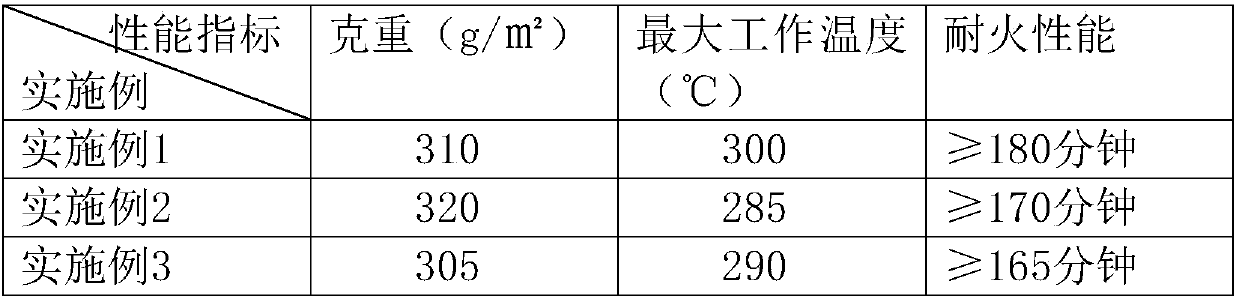

Embodiment 1

[0035] The invention discloses a melt-blown fireproof composite fiber nonwoven fabric, which is prepared from the following components according to mass percentage: 30 parts of plant fibers, 40 parts of fireproof fibers and 20 parts of silicon rubber.

[0036] The plant fiber is bamboo fiber.

[0037] The fireproof fiber is basalt fiber.

[0038] The invention also discloses a method for preparing the above-mentioned melt-blown fireproof composite fiber non-woven fabric, the steps are as follows:

[0039] (1), the plant fibers and fireproof fibers are opened twice;

[0040] (2), the plant fibers and fireproof fibers after opening are then laid by a web-laying machine and carded by a carding machine;

[0041] (3) Carry out hot air bonding, and then spray the bonded fibers to the receiving device with high-speed horizontal and low-speed longitudinal movement and form fiber cloth through air cooling;

[0042] (4) Unfold the prepared fiber cloth, and use a calender to evenly ca...

Embodiment 2

[0044] The invention discloses a melt-blown fireproof composite fiber nonwoven fabric, which is prepared from the following components according to mass percentage: 40 parts of plant fibers, 30 parts of fireproof fibers and 15 parts of silicon rubber.

[0045] The plant fiber is flax fiber.

[0046] The fireproof fiber is ceramic fiber.

[0047] The invention also discloses a method for preparing the above-mentioned melt-blown fireproof composite fiber non-woven fabric, the steps are as follows:

[0048] (1), the plant fibers and fireproof fibers are opened twice;

[0049] (2), the plant fibers and fireproof fibers after opening are then laid by a web-laying machine and carded by a carding machine;

[0050] (3) Carry out hot air bonding, and then spray the bonded fibers to the receiving device with high-speed horizontal and low-speed longitudinal movement and form fiber cloth through air cooling;

[0051] (4) Unfold the prepared fiber cloth, and use a calender to evenly cal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com