Fire-extinguishment helmet, fire-extinguishment helmet shell body and preparation method of fire-extinguishment helmet shell body

A technology for helmets and shells, which is applied in the field of preparation of fire-fighting helmets, fire-fighting helmet shells, and fire-fighting helmet shells, and can solve problems such as time-consuming and laborious, large surface area of helmet shells, and unfavorable mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0086] Embodiment 1, make helmet body

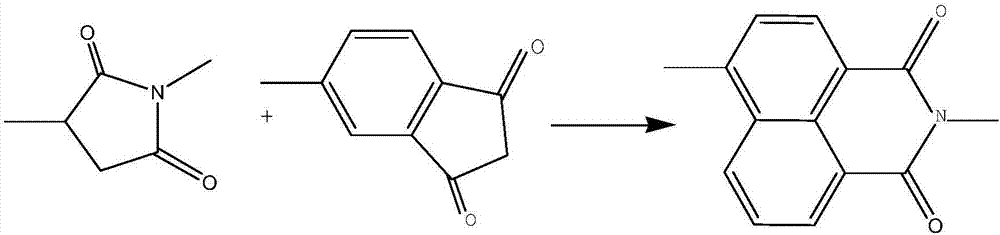

[0087] 1) Synthesis of epoxy resins and curing agents containing imide groups

[0088] a, Synthesis of epoxy resins containing imide groups:

[0089] Add bifunctional epoxy resin, polyimide, and epoxy resin (862) into the reaction kettle at a molar ratio of 1:2:1, stir and heat thoroughly, until the temperature rises to 120°C, the dehydration reaction starts, stir The speed is 200-220 revolutions per minute, fully stirred for 2 hours and then dehydrated for 1 hour. The solution is layered up and down, and the water is removed from the top. Continue to heat until the temperature rises to 250°C, and the cross-linking reaction begins. Take out the reaction after 24 hours of reaction. For the sample, use filter paper to filter the sample, wait until no particulate matter appears, the reaction is completed, and cool down for use.

[0090] b. Synthesis of curing agent:

[0091] Add 15ml of trimethylhexamethylenediamine and 30ml of 3-ethynyl...

Embodiment 2

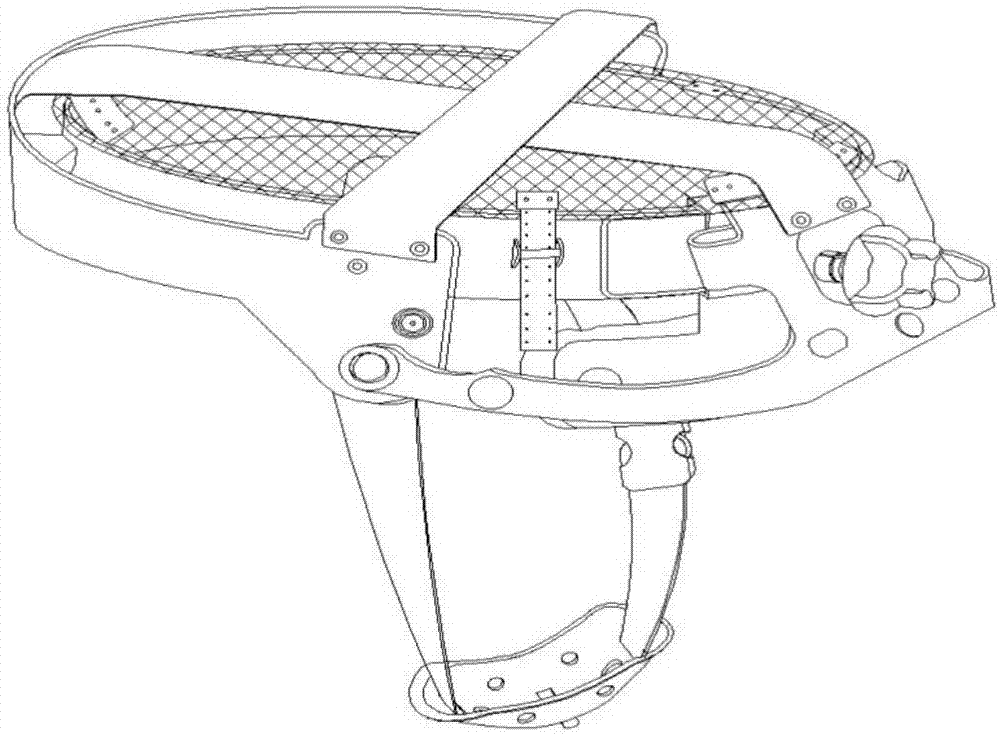

[0105] Embodiment 2, fire helmet

[0106] The fire extinguishing helmet provided by the present invention comprises a helmet shell, a suspension system, a shawl, a mask, an aramid velcro and a snap button; the suspension system is fixed inside the helmet shell; wherein the suspension system includes a helmet lining and a mesh belt on top of the head , cap ring, chin rest and chin strap; the helmet cap liner is assembled from hard plastic parts and soft plastic parts; The hard plastic part is composed of an adjusting fixed frame, an adjusting hand wheel and an adjusting gear; among them, the adjusting fixed frame has a lock channel;

[0107] The shawl and the suspension system are connected by aramid velcro and snap buttons, and are located at the rear of the helmet shell; the face shield is installed on the outer surface of the helmet shell, and can be turned back and forth; the helmet shell used is the helmet shell obtained in Example 1 body.

[0108] In the helmet cap line...

Embodiment 3

[0112] Embodiment 3, helmet performance detection

[0113] According to the requirements of GA44-2015 "Fire Helmet", 12 helmet samples obtained in Example 2 were submitted for inspection, and the specific results are shown in Table 6:

[0114] Table 6. Test results of helmet performance (GA44—2015)

[0115]

[0116]

[0117]

[0118] It can be seen from Table 6 that the surface of the helmet provided by the present invention is fully filled, the inner surface of the helmet shell is smooth, and has special properties such as impact resistance, puncture resistance, combustion resistance, high temperature resistance, and electrical insulation. It is at the domestic leading level and has important application value .

PUM

| Property | Measurement | Unit |

|---|---|---|

| weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com