Heat exchanger

a heat exchanger and composite technology, applied in indirect heat exchangers, lightening and heating apparatus, transportation and packaging, etc., can solve the problems of reducing the length of the refrigerant tubes that form the condenser, reducing the heat exchange rate of the refrigerant radiator as a whole, and reducing the heat exchange rate of the subcooling portion of the refrigerant radiator

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

first embodiment

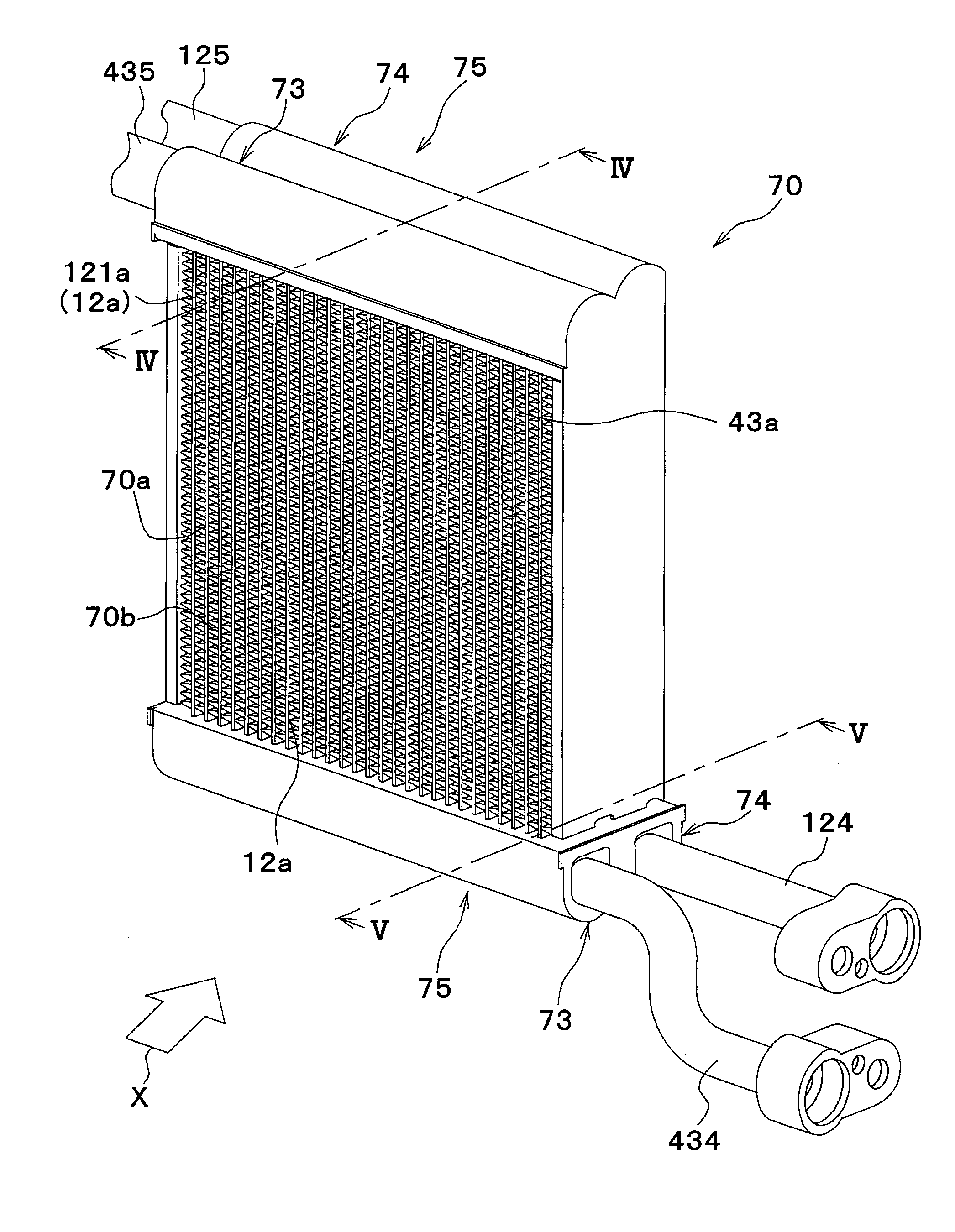

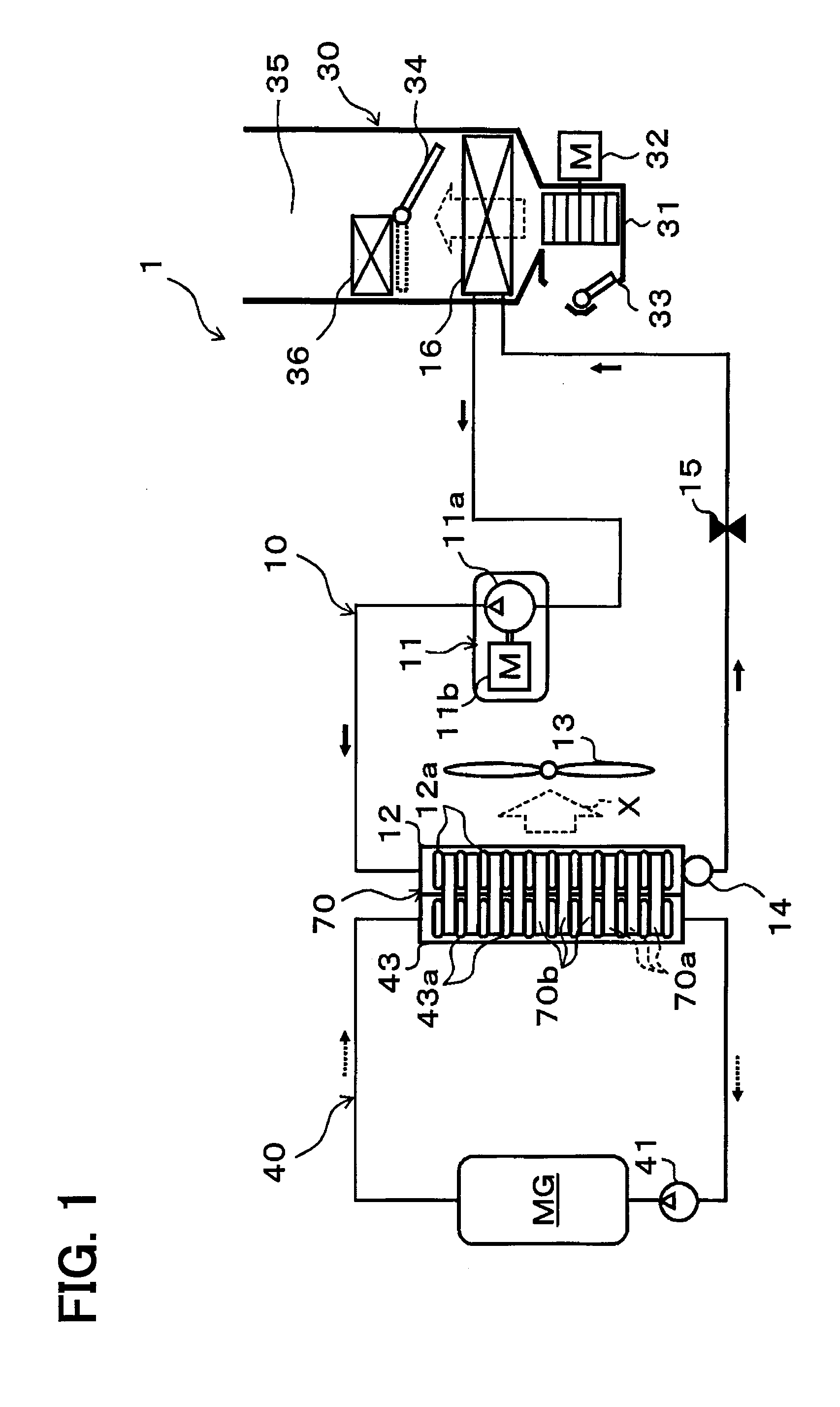

[0032]A first embodiment of the present disclosure will be described with reference to FIG. 1 to FIG. 7. In the present embodiment, a heat exchange system of the present disclosure is applied to a vehicle air conditioning apparatus 1 for so-called a hybrid vehicle that obtains a drive force for traveling a vehicle from an internal combustion engine (an engine) and a traveling electric motor MG.

[0033]The hybrid vehicle is capable of being switched between a traveling state in which the engine is activated or stopped depending on a traveling load of the vehicle and a drive force is obtained both from the engine and the traveling electric motor MG to travel and a traveling state in which the engine is stopped and the drive force is obtained only from the traveling electric motor MG to travel. Accordingly, in the hybrid vehicle, a vehicle fuel efficiency for normal vehicles which obtain the drive force for traveling the vehicle only from the engine can be improved.

[0034]The heat exchang...

second embodiment

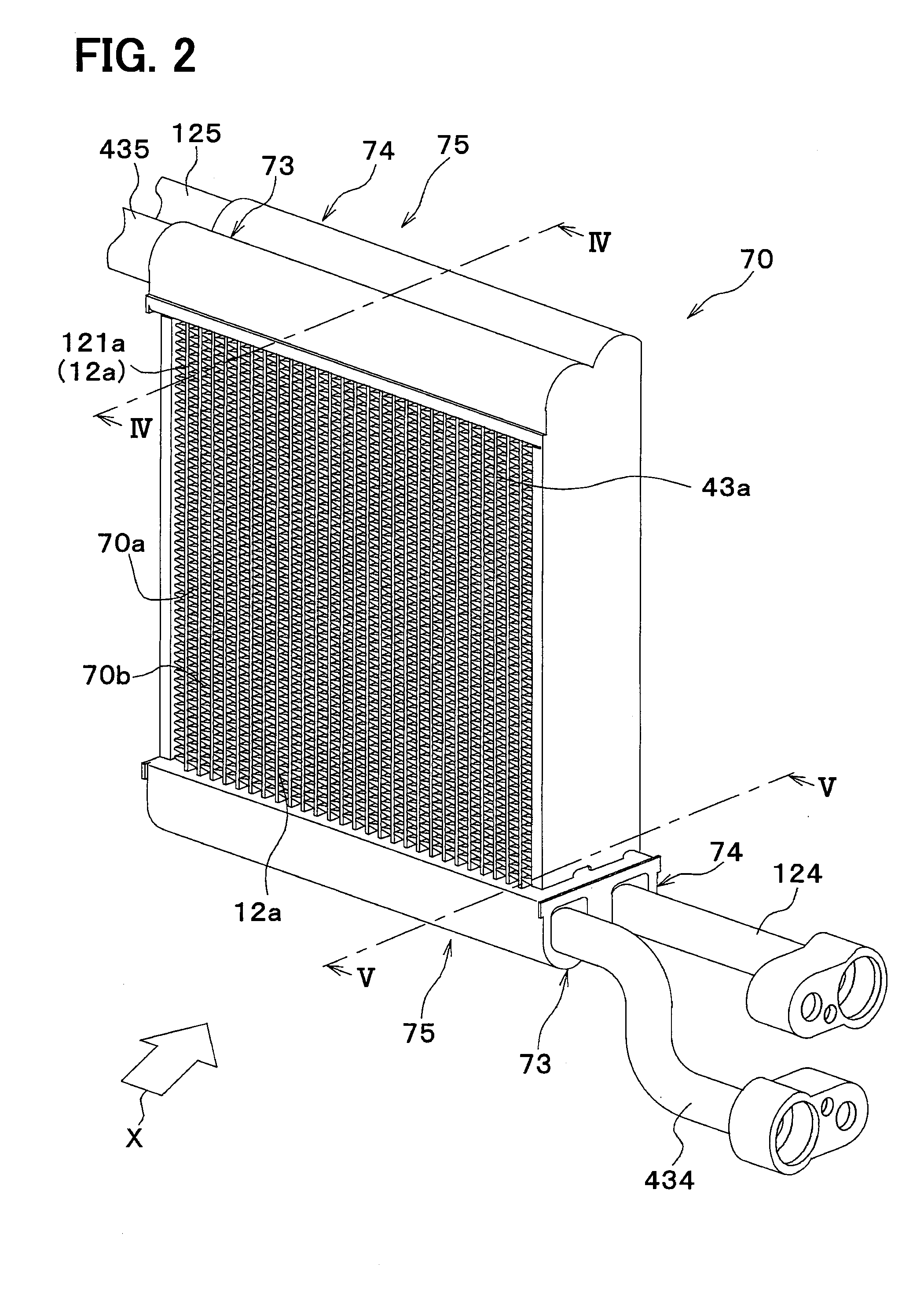

[0142]Subsequently, a second embodiment of the present disclosure will be described with reference to FIG. 8. In comparison with the first embodiment described above, the second embodiment is different in a point that a first core portion 701 includes also a coolant tube 43a. In FIG. 8, refrigerant tubes 12a are illustrated with diagonal hatching and the coolant tube 43a is illustrated by dot hatching for clarifying the drawing.

[0143]As illustrated in FIG. 8, the first core portion 701 of a composite-type heat exchanger 70 of the present embodiment is provided with the coolant tube 43a. In the present embodiment, although the number of the refrigerant tubes 12a (nine in this example) is larger than the number of the coolant tube 43a (one in this example) in the first core portion 701. Surfaces of outer fins 70b are provided with a plurality of shutter-like louvers 700 formed along the flowing direction of the outside air by cutting and rising.

[0144]In the outer fin 70b between the m...

third embodiment

[0149]Subsequently, a third embodiment of the present disclosure will be described with reference to FIG. 9. The third embodiment is different in the flow of the refrigerant of the first core portion 701 in comparison with the first embodiment.

[0150]As illustrated in FIG. 9, an upstream side partitioning member 732a configured to partition the upstream side coolant space 731 in the internal space of the second upstream side tank unit 730b into two parts in the longitudinal direction is arranged in the second upstream side tank unit 730b. A space closer to the first core portion 701 (the left side on the paper plane) out of the two internal spaces of the tank partitioned by the upstream side partitioning member 732a (hereinafter, referred to as an upstream side refrigerant space 731a) communicates with the most downstream refrigerant tubes 121a, but not communicate with coolant tube 43a. A refrigerant outflow pipe 125 is connected to the upstream side refrigerant space 731a.

[0151]In...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com