Multi-tube heat exchanger

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

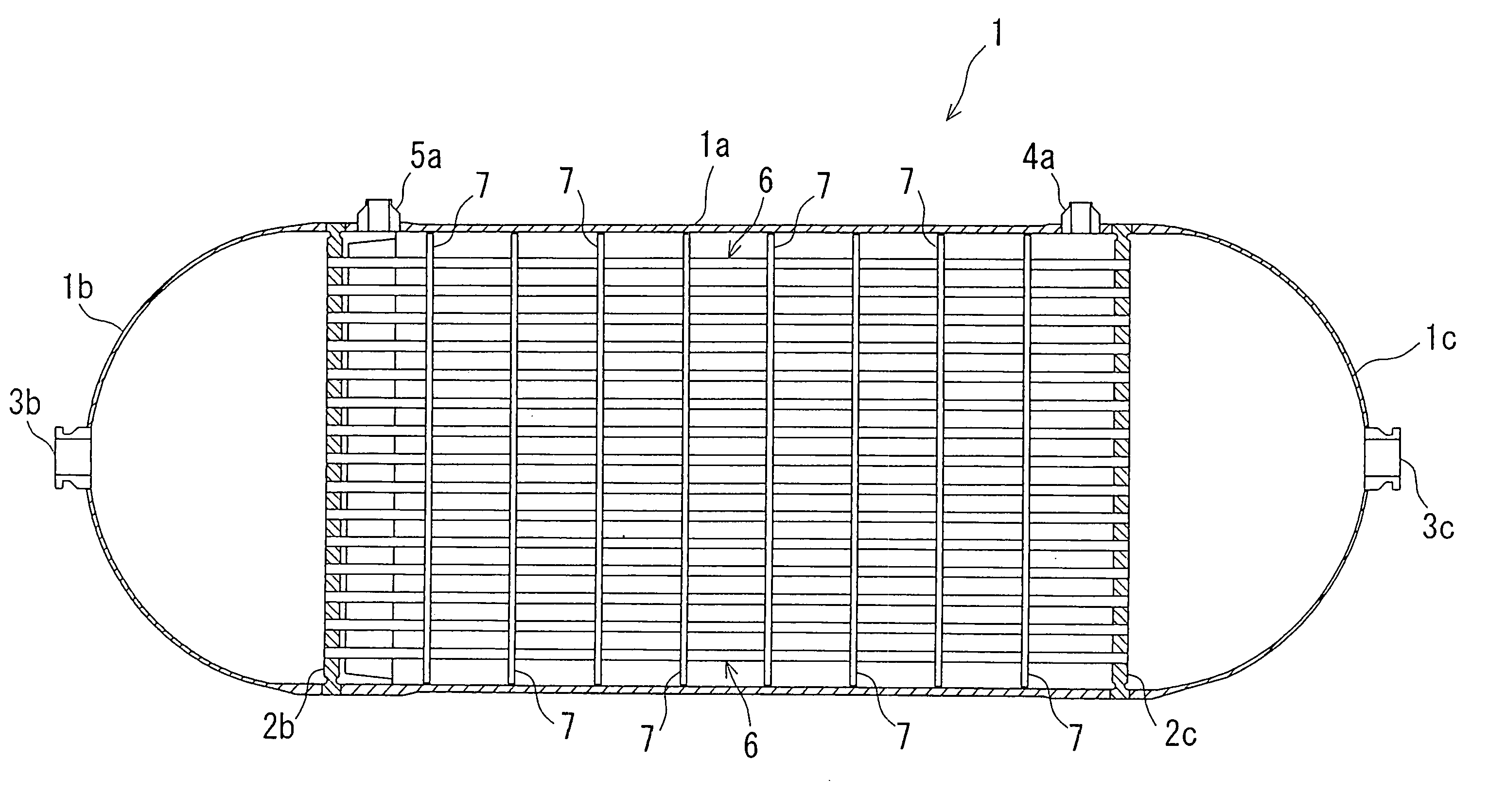

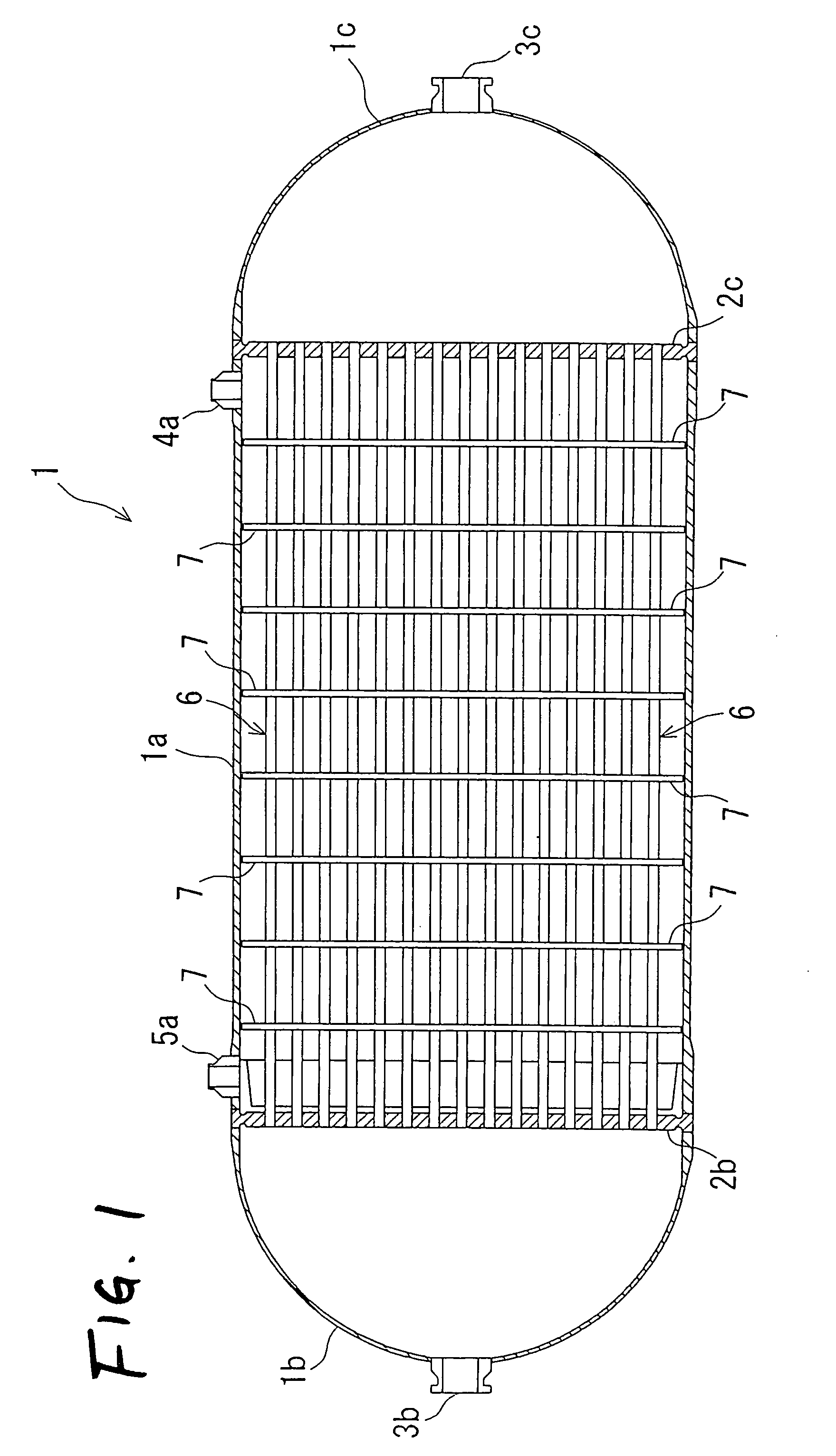

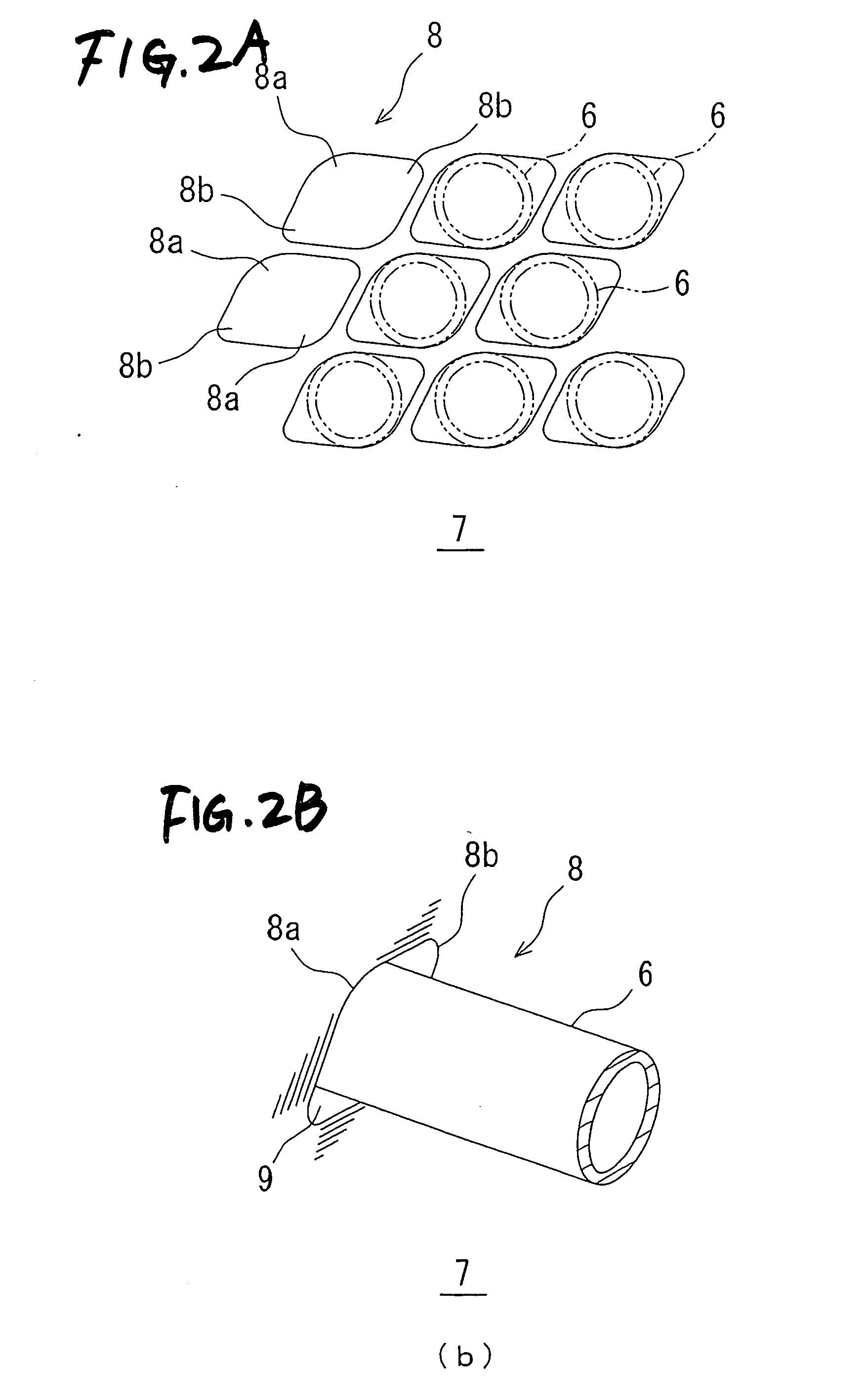

[0024] Now, an embodiment of the invention will be described referring to FIGS. 1 and 2A and 2B.

[0025] An outer shell 1 mainly includes a body part 1a in a cylindrical shape, and head parts 1b, 1c in a semicircular shape which are continued from both ends of the body part la. Inside the outer shell 1, there are provided partition walls 2b, 2c for separating a space inside the body part 1a from spaces inside the head parts 1b, 1c. The head parts 1b, 1c are respectively provided with fluid ports 3b, 3c which are open to the exterior and communicated with the spaces defined by the partition walls 2b, 2c. The body part 1a is provided with fluid ports 4a, 5a which are open to the exterior and communicated with the spaces defined by the partition walls 2b, 2c.

[0026] Further, a number of tubes 6 bundled into a tube bundle are bridged between the partition walls 2b, 2c. Both ends of the tubes are respectively communicated with the spaces inside the head parts 1b, 1c which are defined by t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com