Solid particle heat exchanger

A solid powder, heat exchanger technology, applied in the direction of heat exchanger types, indirect heat exchangers, heat exchange equipment, etc., can solve the problems of poor technical and economic indicators, easy wear and tear of heat exchangers, and large power consumption, and achieve good results. Energy saving effect, improved heat exchange efficiency, less power consumption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

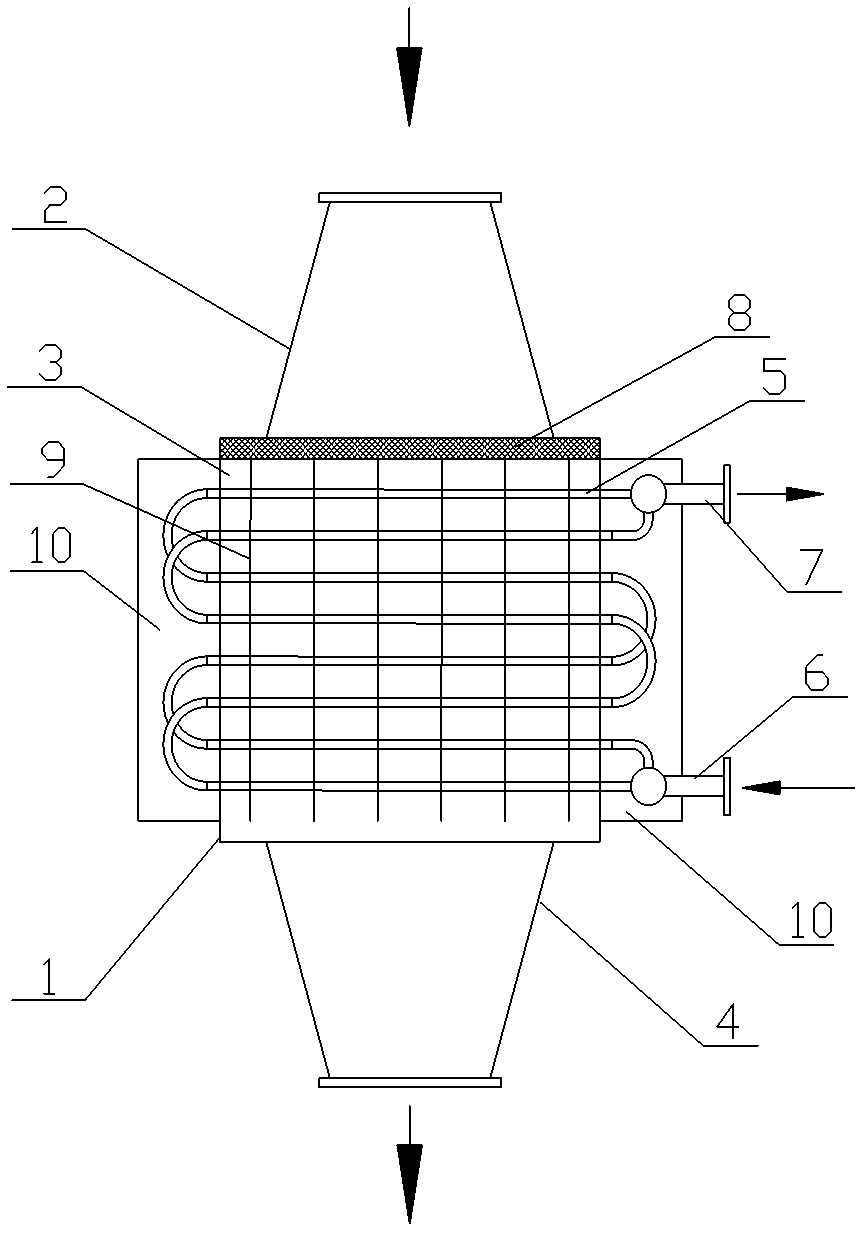

[0040] The basic structure of the solid powder heat exchanger in this embodiment is as follows: figure 1 As shown, it includes a cylindrical shell 1. The top of the shell 1 has an upper connection box 2 for receiving powder particles, a heat exchange chamber 3 in the middle, and a lower connection box 4 for discharging powder particles at the bottom. The heat exchange chamber 3 is equipped with a heat exchange tube bundle. 5. The heat exchange tube bundle 5 is provided with a fluid inlet 6 and a fluid outlet 7 on the shell 1, and the fluid inlet 6 is externally connected to a heat transfer fluid source; a distributor 8 is provided between the upper connection box 2 and the heat exchange chamber 3 .

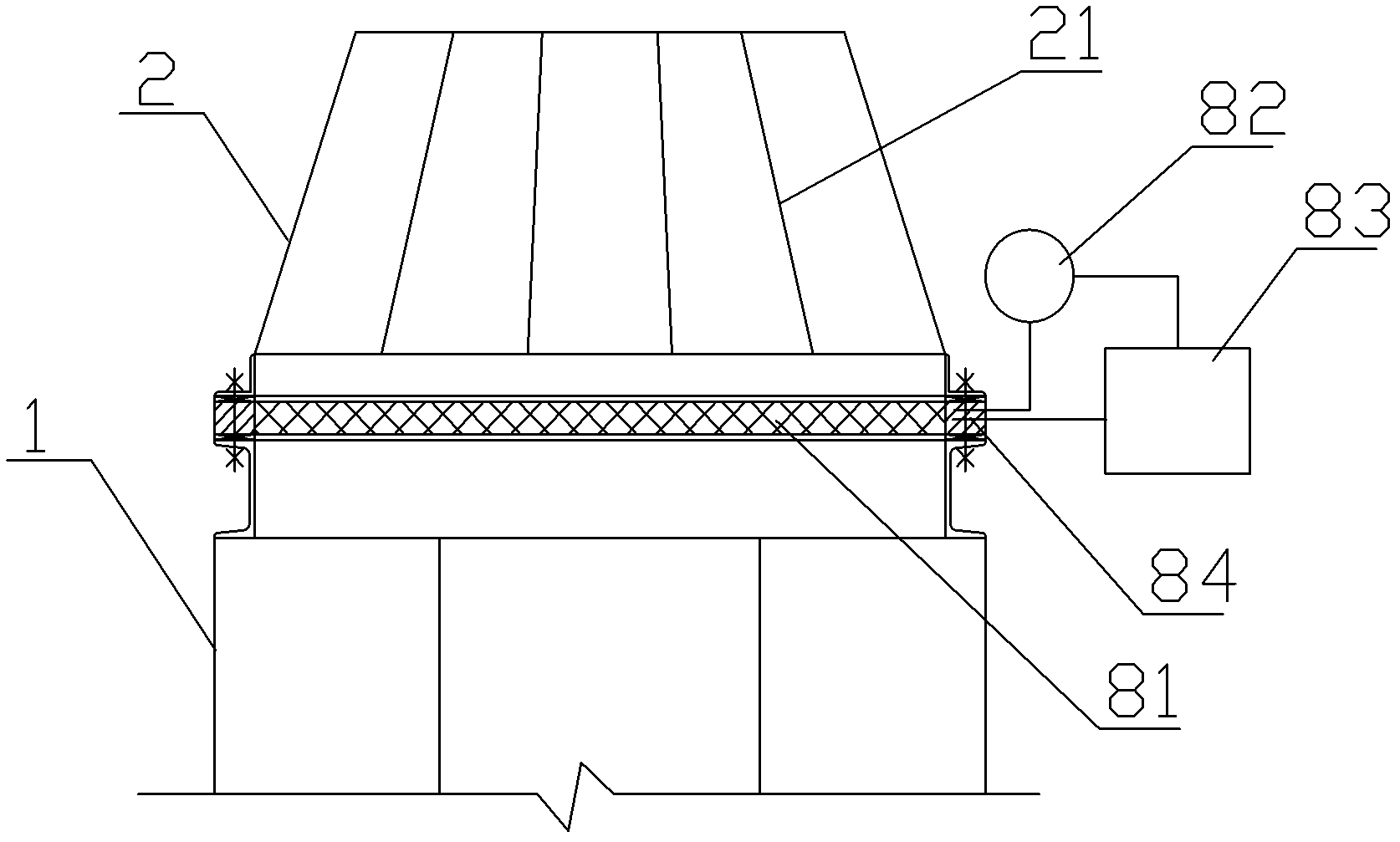

[0041] Such as figure 2 As shown, the dispenser 8 includes a silk screen layer 81, and the silk screen layer 81 is connected with the control device; connection, the sensing end of the weight sensor 82 and the output end of the vibrator 83 are connected to the silk screen layer ...

Embodiment 2

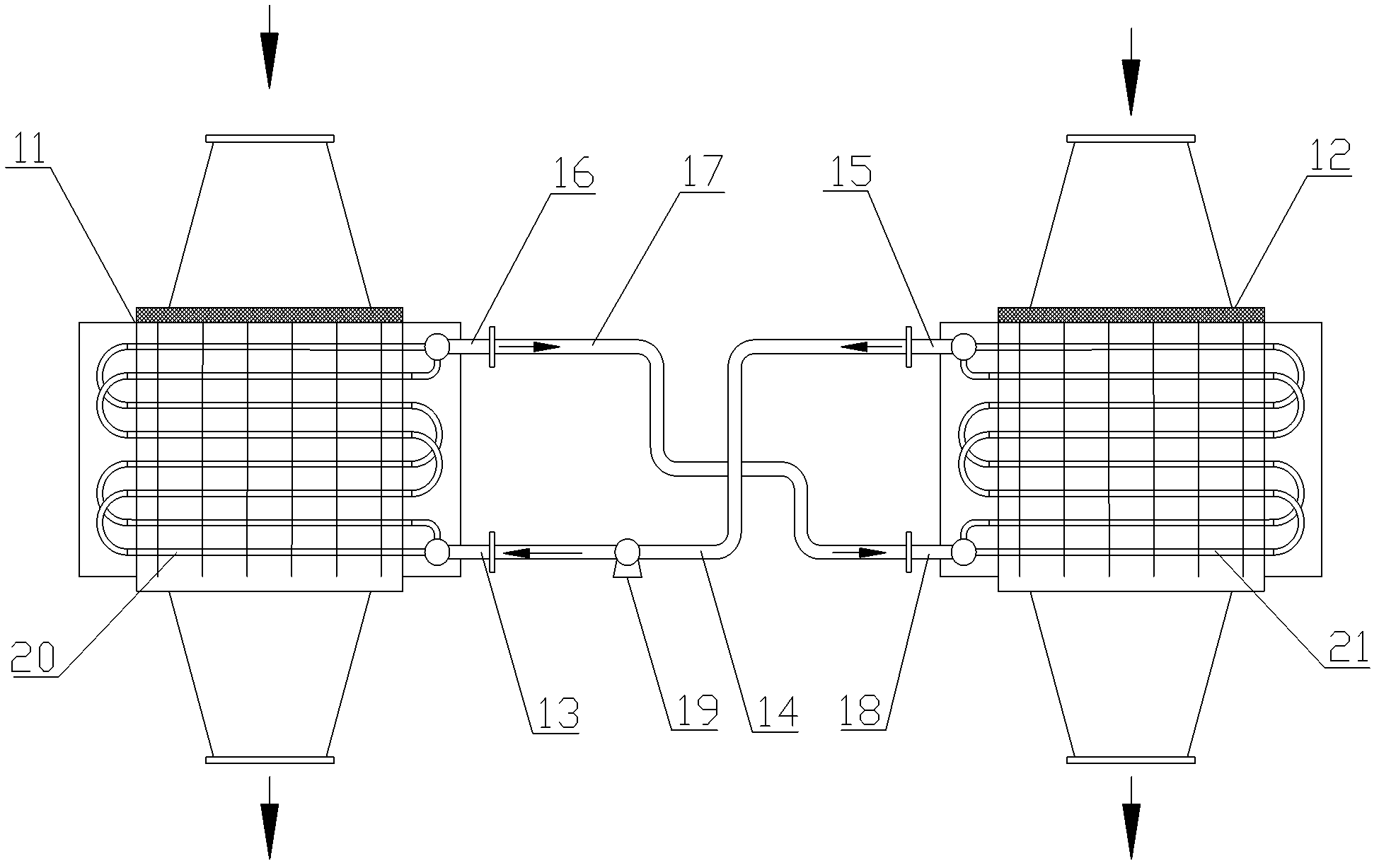

[0050] This embodiment is a solid powder heat exchange system using the solid powder heat exchanger in Embodiment 1, including a first solid powder heat exchanger 11 for cooling powder, a second solid powder heat exchanger for heating powder Heat exchanger 12; the fluid inlet 13 of the first solid powder heat exchanger 11 communicates with the fluid outlet 15 of the second solid powder heat exchanger 12 through the first pipeline 14, and the fluid of the first solid powder heat exchanger 11 The outlet 16 communicates with the fluid inlet 18 of the second solid powder heat exchanger 12 through the second pipeline 17, the heat exchange tube bundle 20 of the first solid powder heat exchanger 11, the heat exchange of the second solid powder heat exchanger 12 The tube bundle 21 , the first pipeline 14 and the second pipeline 17 form a fluid circulation loop; the fluid circulation loop is filled with heat transfer fluid; the first pipeline 14 has a fluid pump 19 .

[0051] When in u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com