Plate type heat exchanger

一种板式换热器、端板的技术,应用在换热器外壳、间接换热器、换热器类型等方向,达到优化换热过程、强化换热、拓宽实际应用范围和条件的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

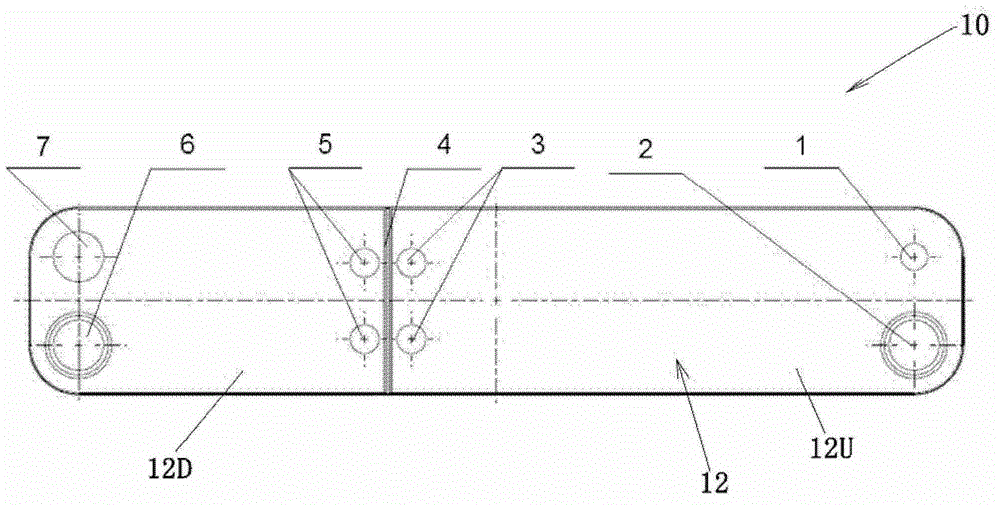

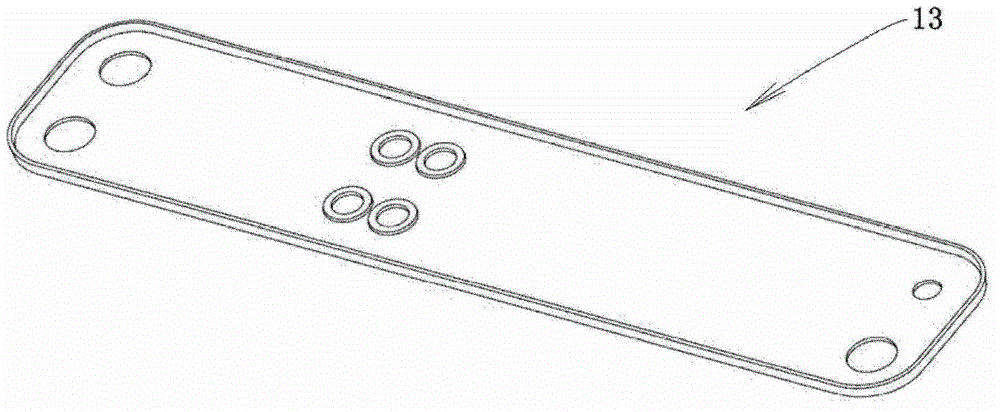

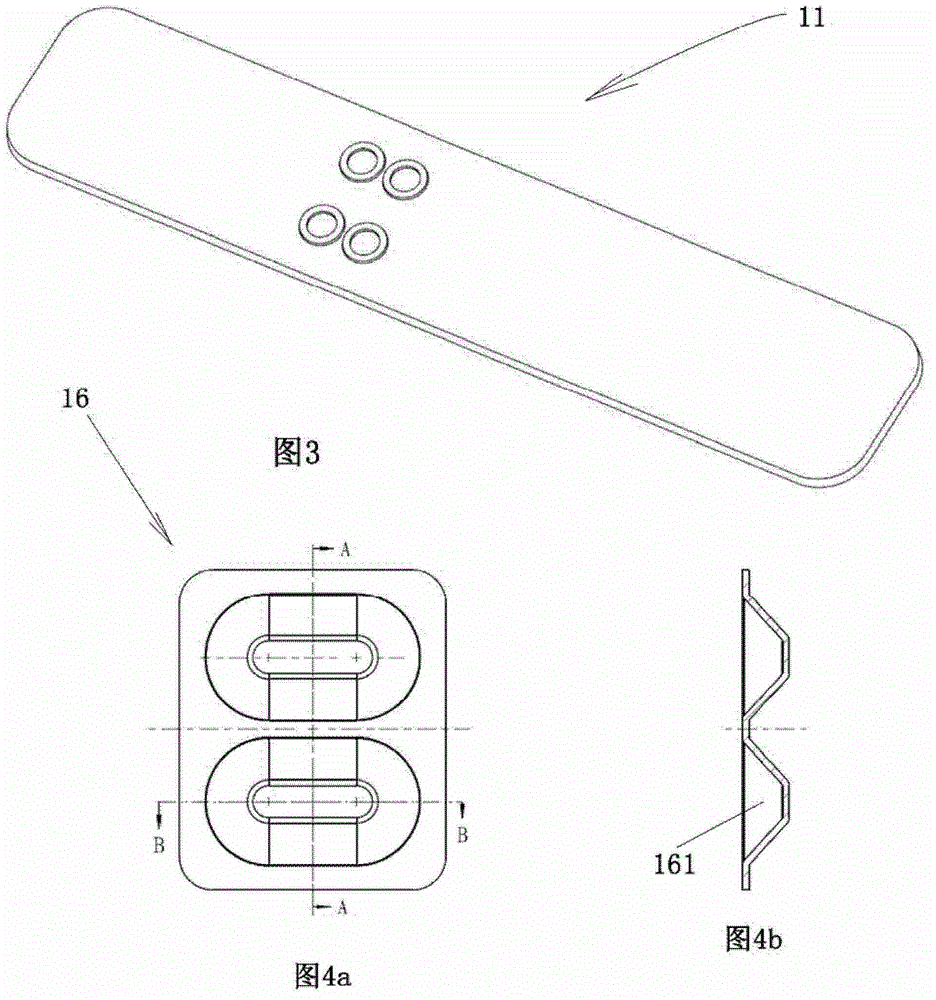

[0042] see Figure 1 to Figure 8 , The plate heat exchanger 100 according to the embodiment of the present invention includes: a heat exchange plate 10 and end plates 11 and 13 forming a first fluid channel 12 and a second fluid channel. End plates 11 and 13 are arranged on the outer sides of the heat exchange plate 10 .

[0043] Such as figure 2 and 3 As shown, the end plates 11 and 13 respectively have the same through holes as the sides of the corresponding heat exchange plate 10 . The heat exchange plate 10 may be integrated. The plate heat exchanger 100 further comprises: a first fluid inlet 1 , a first fluid outlet 7 , a second fluid outlet 2 (for the counter-flow evaporator) and a second fluid inlet 6 (for the counter-flow evaporator). A first fluid, such as refrigerant, flows in the first fluid passage 12, and a second fluid, such as water, flows in the second fluid passage. The aperture of the first fluid inlet 1 may be smaller than the aperture of the first flu...

Embodiment 2

[0062] Such as Figure 9 and 10 As shown, for a wide plate heat exchanger 100 with a small aspect ratio, rectangular flow holes or multiple flow holes can also be used to realize the communication and mixing of the upstream area and the downstream area, such as Figure 9 and Figure 10 shown. That is, the outlet 3 of the first fluid passage upstream portion 12U and the inlet 5 of the first fluid passage downstream portion 12D have a substantially rectangular shape or the plate heat exchanger 100 has a plurality of outlets 3 of the first fluid passage upstream portion 12U and a plurality of second fluid passages. An inlet 5 of the downstream portion 12D of the fluid passage.

Embodiment 3

[0064] The present invention is also applicable to dual circle evaporators. Figure 11 is a schematic diagram of a dual-flow path refrigerant plate heat exchanger 100 . The plate heat exchanger 100 has two refrigerant circulation loops, both of which share a water circulation system for heating. Figure 11 Among them, W represents the circuit of water, R1 represents the circuit of the first refrigerant, and R2 represents the circuit of the second refrigerant. The present invention's solution to this type of application is as Figure 12 As shown, for the unilateral flow channel, 1 is the inlet of the first refrigerant (the first fluid inlet), 3 and 5 are the upstream and downstream communication plate holes (the outlet of the upstream part of the first fluid channel 12U and the first fluid channel) 1' is the inlet of the second refrigerant (first fluid inlet), 3 and 5 are its upstream and The downstream connecting plate hole (the outlet of the upstream part 12U of the first ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com