Anti-scaling agent used for hydrogenation plant and its preparation method and application

A technology of hydrogenation unit and antiscalant, which is applied in the direction of treatment equipment corrosion/scaling inhibition, petroleum industry, refining to remove heteroatoms, etc. Possess problems such as polymerization inhibition to achieve the effects of preventing deposition, non-toxic and harmless environment, and reducing bed pressure drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The structure and preparation method of the new compound A.

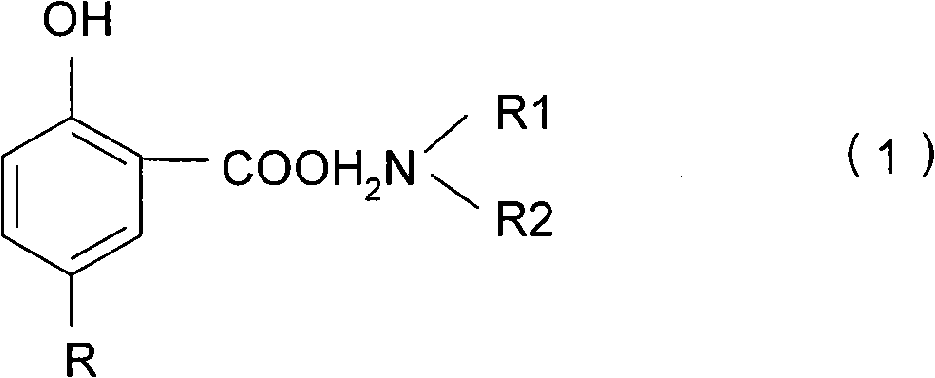

[0037] 1. The structure of the new compound A

[0038]

[0039] 2. Preparation method

[0040] Place 114g (0.5mol) dodecyl salicylic acid, 134.5g (0.5mol) octadecyl primary amine and 50g xylene in a three-necked flask equipped with a thermometer, a stirrer, and a condenser tube, and heat to 80~ React at 90°C for 1 hour, filter and evaporate the solvent to obtain the new compound antiscalant A.

Embodiment 2

[0042] The structure and preparation method of the new compound B.

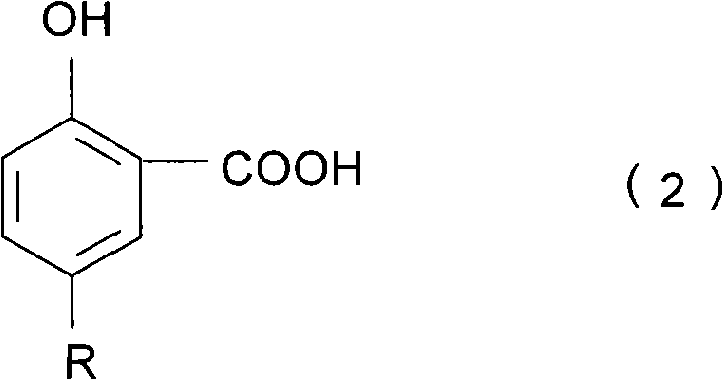

[0043] 1. The structure of the new compound B

[0044]

[0045] 2. Preparation method

[0046] Put 128g (0.5mol) tetradecyl salicylic acid, 91.5g (0.5mol) dodecyl primary amine and 50g aromatic hydrocarbon solvent oil (distillation range is 180~200°C) in a condenser equipped with a thermometer, agitator, In a three-neck flask, heat to 80-90°C for 1 hour, filter and evaporate the solvent to obtain the new compound antiscalant B.

Embodiment 3

[0048] The structure and preparation method of the new compound C.

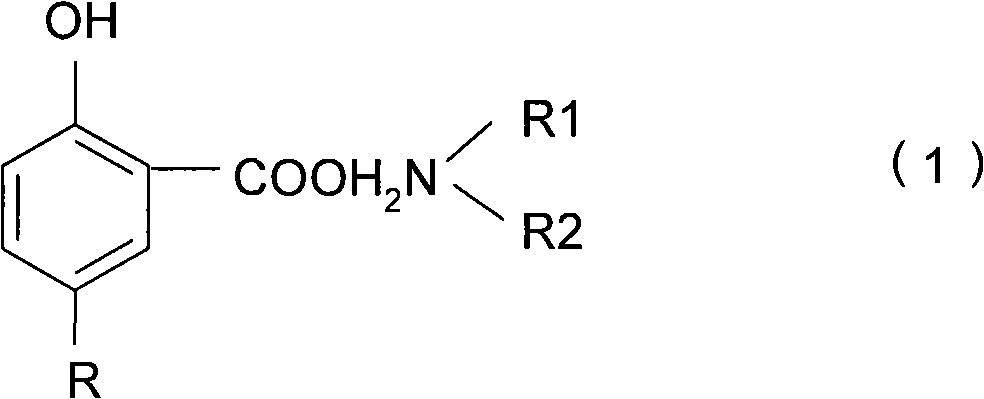

[0049] 1. The structure of the new compound C

[0050]

[0051] 2. Preparation method

[0052] Put 142g (0.5mol) of hexadecyl salicylic acid, 30.5g (0.5mol) of monoethanolamine and 36g of aromatic solvent oil (distillation range 180-200°C) into a three-necked flask equipped with a thermometer, a stirrer, and a condenser , heated to 40-50°C for 1 hour, filtered and evaporated to obtain the new compound antiscalant C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com