Heat pump type air-conditioning heat exchanger with heat exchange working medium flow direction and flow path number in synchronous change

A technology of synchronously changing and heat-exchanging working medium, which is applied in household heating, heating methods, household heating, etc., can solve the problems of long flow path, reduced heat exchange performance, and high refrigerant flow rate, etc. reliability effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

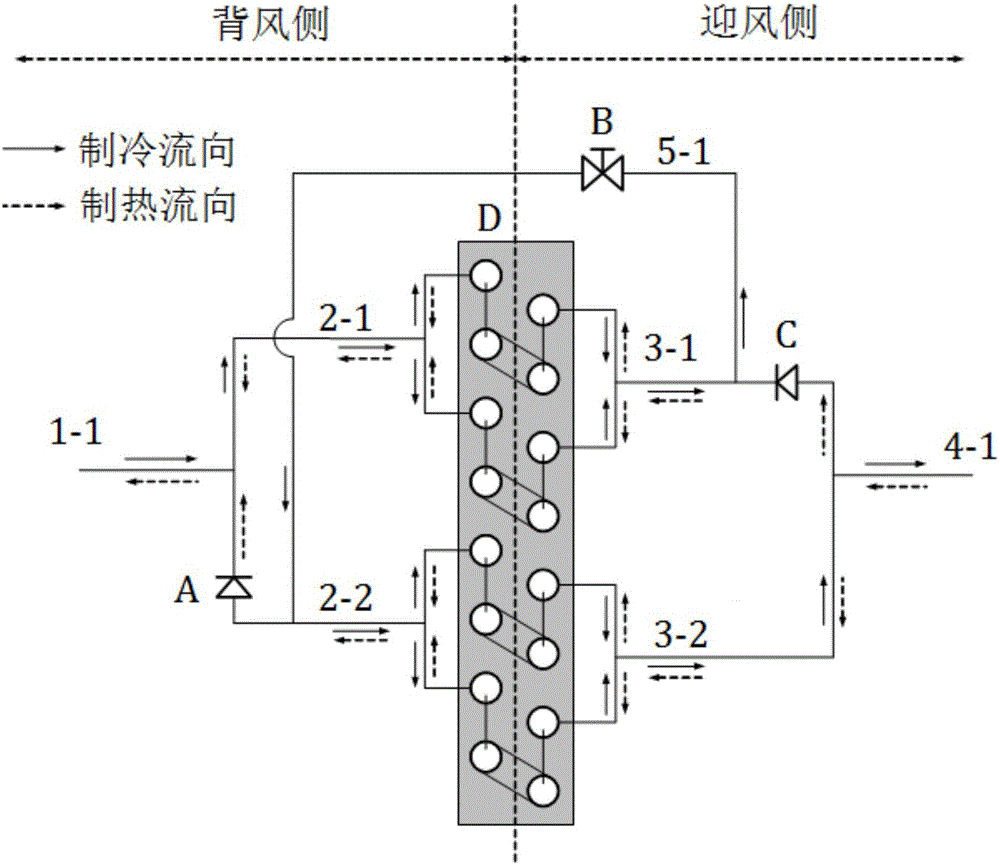

[0015] Such as figure 1 As shown, the present embodiment includes: main pipe 1-1 on the leeward side, first branch pipe 2-1 on the leeward side, second branch pipe 2-2 on the leeward side, main pipe 4-1 on the windward side, first branch pipe 3-1 on the windward side, The second branch pipe 3-2 on the side and the heat exchanger D, wherein: the heat exchanger D is provided with 2n flow paths, the main pipe 1-1 on the leeward side is connected with the first branch pipe 2-1 on the leeward side and the second branch pipe 2-1 on the leeward side respectively. 2 connected, the main pipe 4-1 on the windward side is connected to the first branch pipe 3-1 on the windward side and the second branch pipe 3-2 on the windward side respectively, and the first branch pipe 2-1 on the leeward side and the first branch pipe 3-1 on the windward side are set correspondingly and They are respectively connected to the leeward side port and the windward side port of the n flow paths in the heat ex...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com