Cooling module

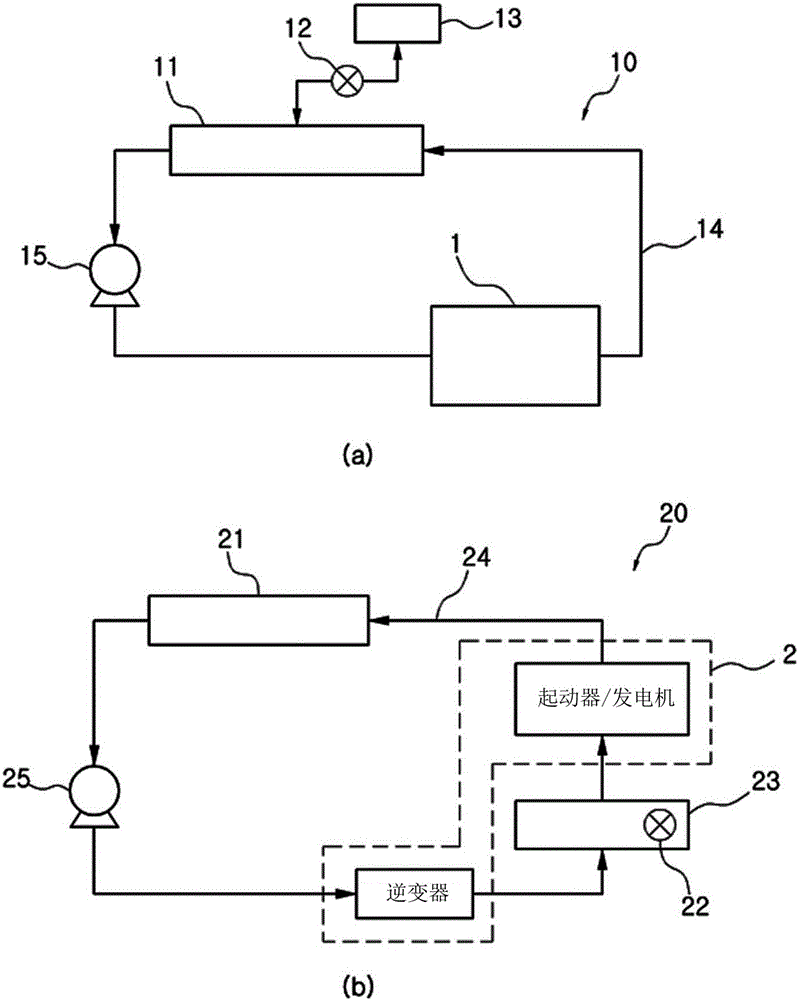

A technology of cooling modules and cooling liquids, applied to the arrangement of cooling combination of power plants, fixed conduit components, lighting and heating equipment, etc., can solve the problem of ensuring the stable performance of the second radiator 21 and affecting the performance of the second radiator 21 etc. to achieve the effect of size reduction, size reduction, and enhanced condensation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0047] Hereinafter, a cooling module 1000 according to an embodiment of the present invention will be described in detail with reference to the accompanying drawings.

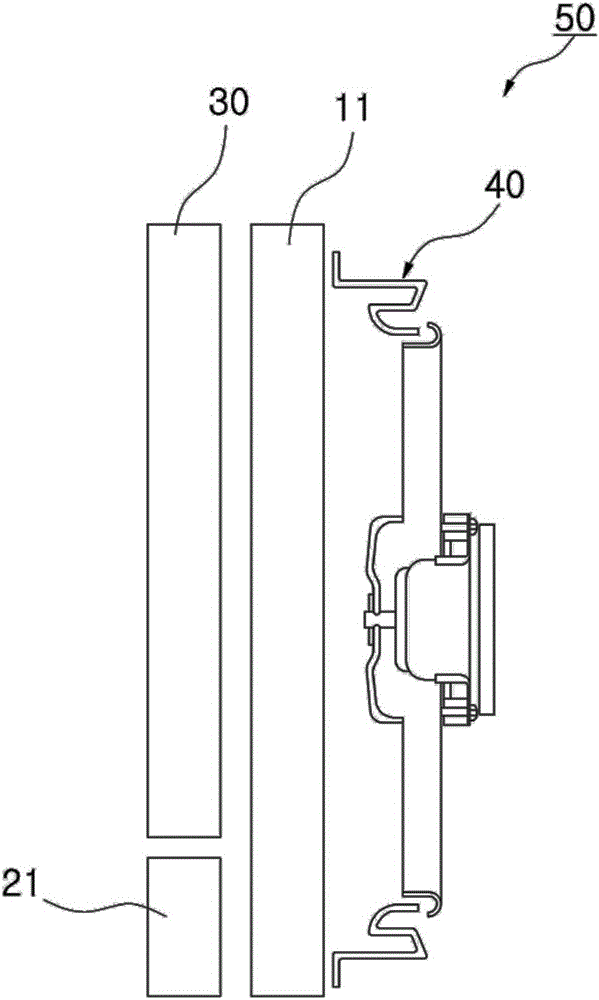

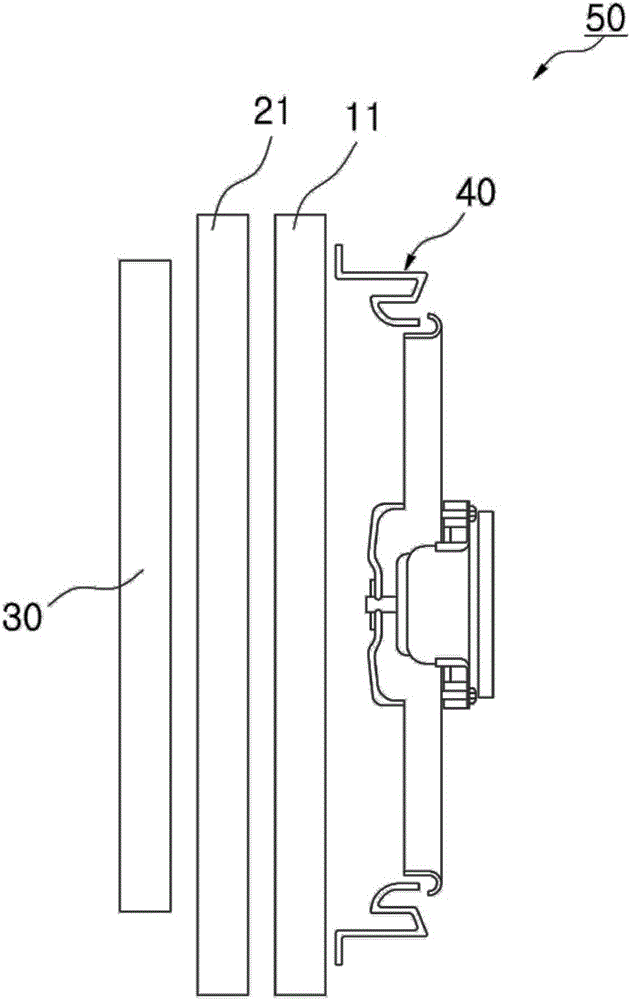

[0048] Figure 4 to Figure 6B is a perspective view, an exploded perspective view and a front view of a cooling module 1000 according to an embodiment of the present invention, Figure 7 is a schematic cross-sectional view of a region forming the second heat sink 200 of the cooling module 1000 according to an embodiment of the present invention, Figure 8 is a schematic cross-sectional view of a region forming the first condenser 300 of the cooling module 1000 according to an embodiment of the present invention.

[0049] The cooling module 1000 according to an embodiment of the present invention includes a first radiator 100 , a second radiator 200 , a first condenser 300 and a second condenser 400 .

[0050] The first radiator 100 (for cooling the components of the fuel cell stack) may include: a pair of wat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com