Gas dehydration and dealkylation method for supersonic vortex tube

A vortex tube and supersonic technology, which is applied in the direction of gas fuel, separation methods, chemical instruments and methods, etc., can solve the problem that the gas-gas heat exchanger cannot fully exchange heat and make full use of the cooling capacity, and the pressure difference between the inlet and outlet of the supersonic vortex tube and other problems to achieve the effect of preventing overpressure explosion or leakage of raw material gas, ensuring smooth operation, and preventing blockage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

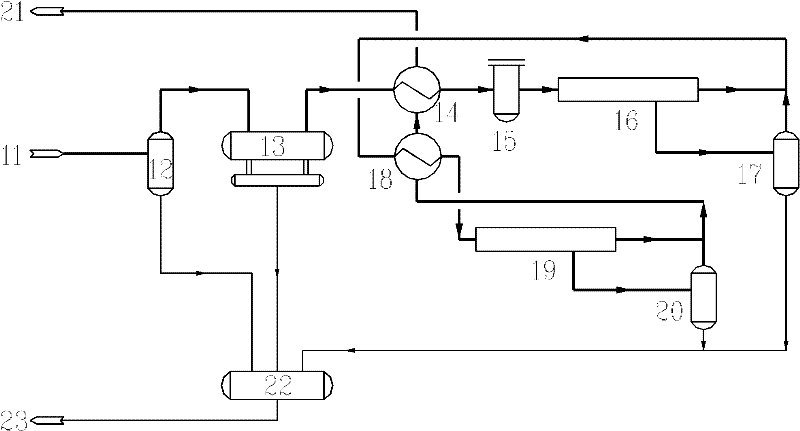

[0045] The implementation of two-stage (or multi-stage) supersonic vortex tube technology is illustrated by taking the dehydration of high-pressure natural gas with two-stage supersonic vortex tube as an example.

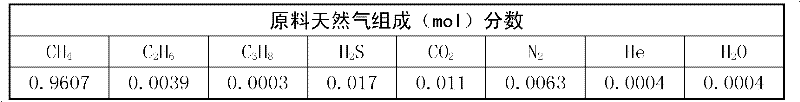

[0046] The inlet pressure of raw natural gas is 10MPa, and its specific composition is shown in Table 1.

[0047] Table 1 Example raw material natural gas composition table

[0048]

[0049]According to the calculation, the hydrate formation temperature of this raw natural gas is 16.35°C. In order to prevent hydrate from clogging the gas-gas heat exchanger, the inlet temperature of the first-stage supersonic vortex tube is set at 20°C.

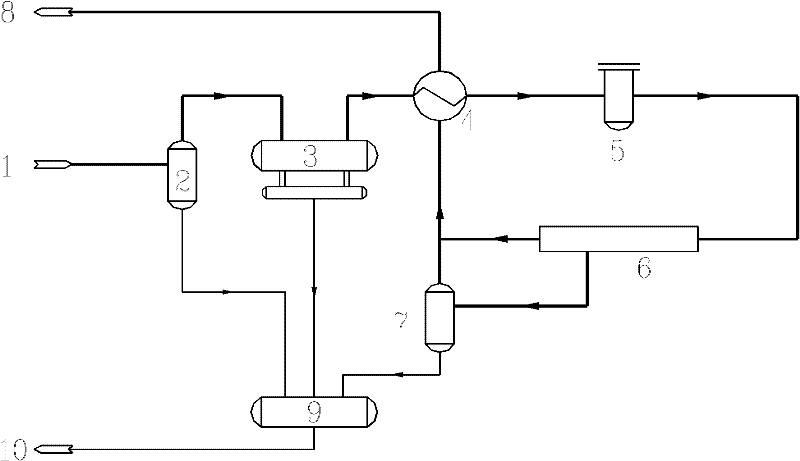

[0050] Its process is as figure 2 shown.

[0051] Containing saturated water and a small amount of free water, the raw material gas 11 with a pressure of 10.0MPa and a temperature of 30°C first enters the raw gas separator 12 and the raw gas filter separator 13 to remove large particles respectively to reduce abrasion under hi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com