Valves having ceramic trim with protected shut-off surfaces

A closing member, non-ceramic technology, used in the field of control valves, which can solve problems such as valve plug and valve seat cracking, crushing or collapsing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

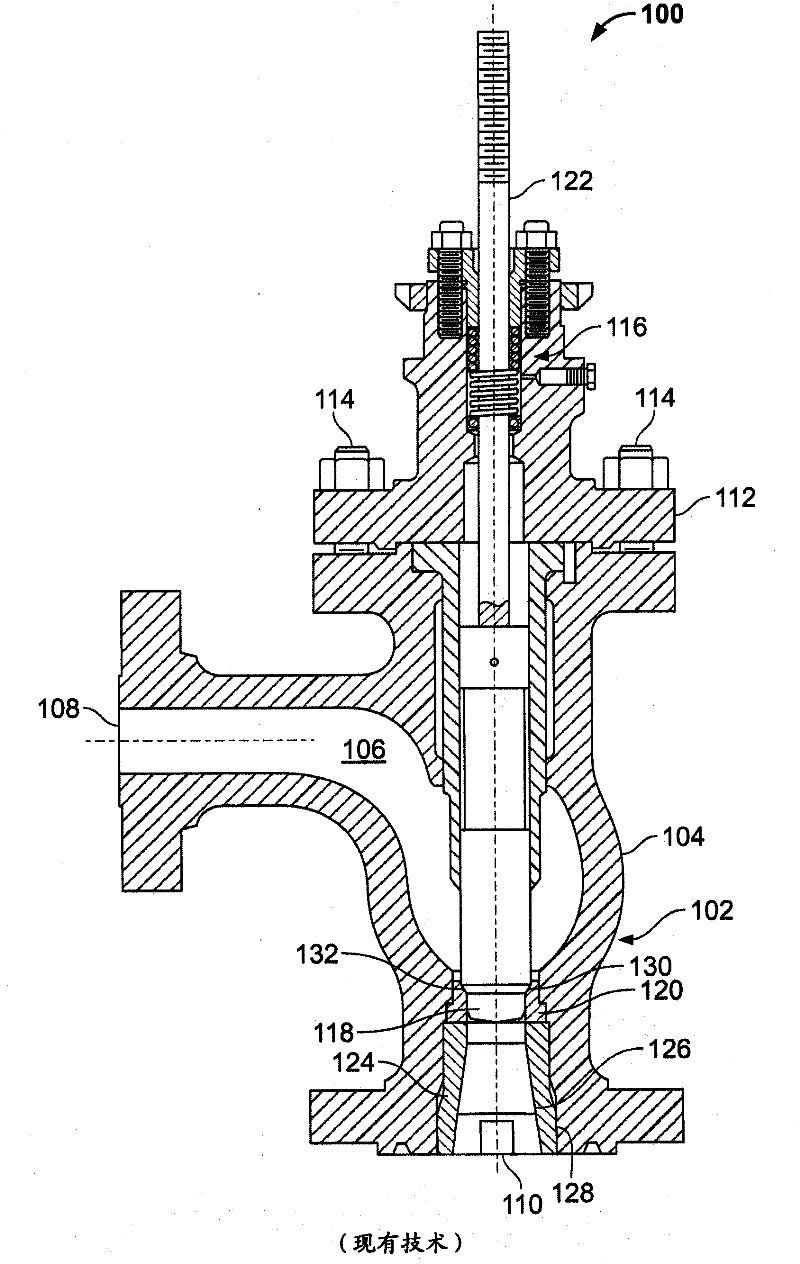

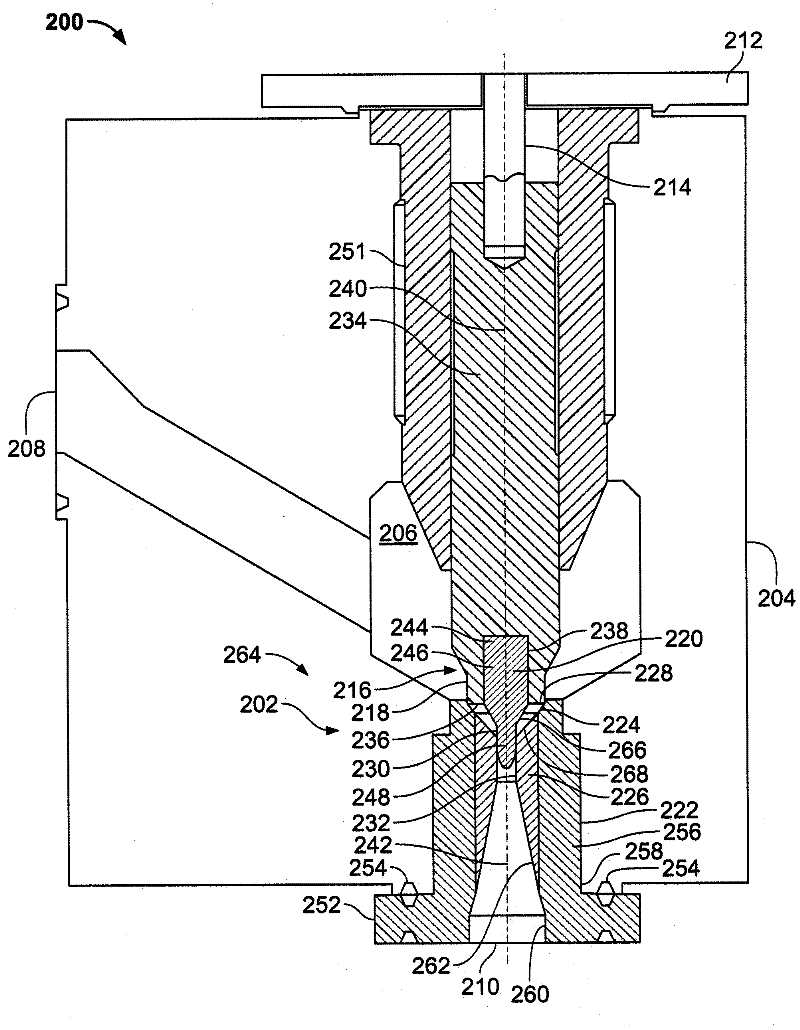

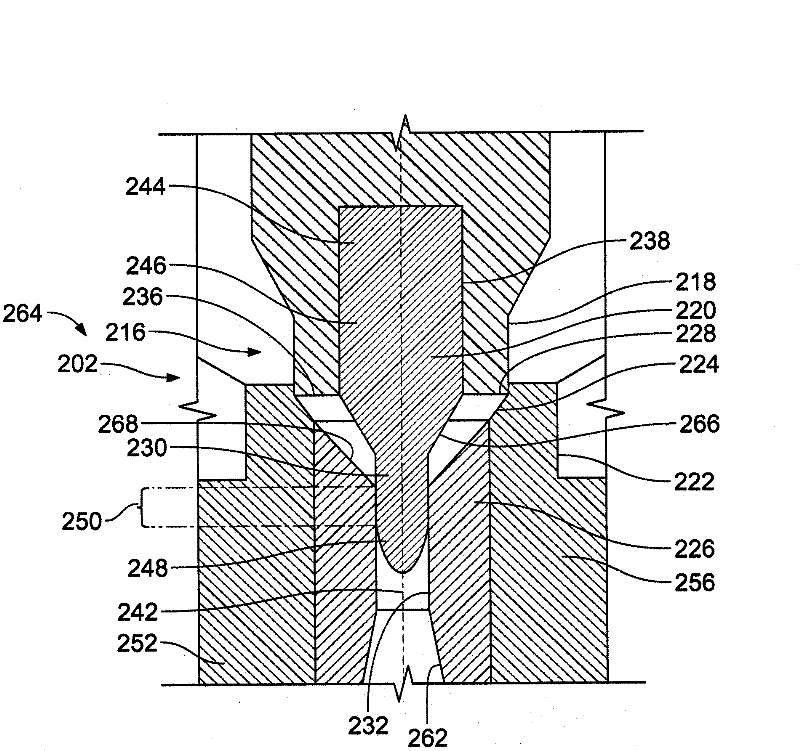

[0016] In general, the example valve trim arrangement described here can be used with heavily aggressive process fluids, such as process fluids (such as hydrogen fluids) that contain entrained particles (such as ceramic catalysts) that often damage or corrode traditional valve trim parts. The example valve trim apparatus described herein significantly increases the operating life of the valve trim compared to the conventional valve trim.

[0017] More specifically, the example valve trim apparatus described herein provides a throttling portion or function that is separate from a closing portion or function. Still further, the example trim device diverts a significant portion of the pressure differential of the process fluid to the restricted portion of the trim device and, thus, minimizes the differential pressure across the closed portion of the trim device . Additionally, relatively large seat loads or thrusts may be applied to the closing portion of the trim device while ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com