Method and device for treating waste gas generated by printing and dyeing wastewater

A printing and dyeing wastewater and waste gas treatment technology, applied in separation methods, chemical instruments and methods, air quality improvement, etc., to achieve the effects of avoiding the increase of operating costs, ensuring the odor load, and reducing the impact load

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

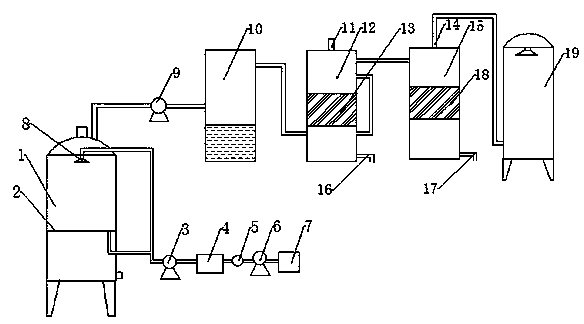

[0051] Fan 9 The humidifier is connected in sequence through the pipeline 10, biological drip filter bed 12, biological filter bed 15;

[0052] The top of the biological dripping bed 12 is the purification gas emissions port I11, the lower part of the biological dripping bed 12 has the waste liquid discharge port I16, the biological drip filter bed 12 has the filler layer Ⅰ13 inside the biological dripping bed;The type of pipeline is connected below and above the filler layer;

[0053] The top 15 of the biological filter bed is Ⅱ14, the lower part of the biological filter bed 15 has the waste liquid emission port II, and the internal filler layer II18 is in the biological filter bed 15;

[0054] The purification gas emission port of the biological filter bed 15 is connected to the absorbent 19 in adjacent places with the deepening treatment of the absorption tower. The upper part of the absorption tower 1 is sprayed.

[0055] The above -mentioned filler layer 2 is located at a hei...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com