Increased safety glue filling drive box and lamps using the increased safety glue filling drive box

A driving box and glue filling technology, which is applied to the safety devices of lighting devices, lighting and heating equipment, lighting devices, etc., can solve the problems of low compatibility, high cost, complicated manufacturing process, etc., to meet explosion-proof requirements and save manufacturing. Cost, the effect of saving the cost of gluing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

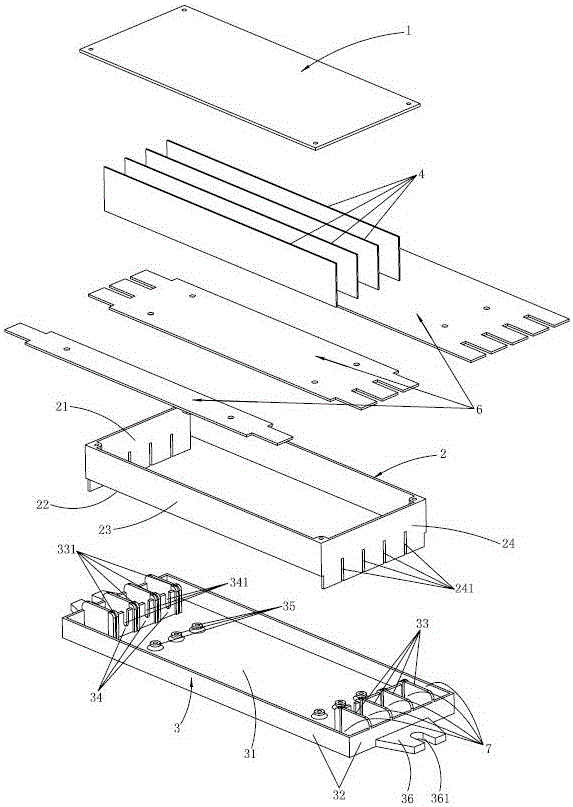

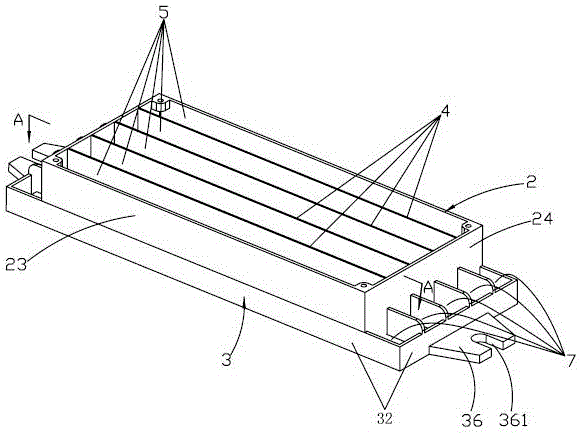

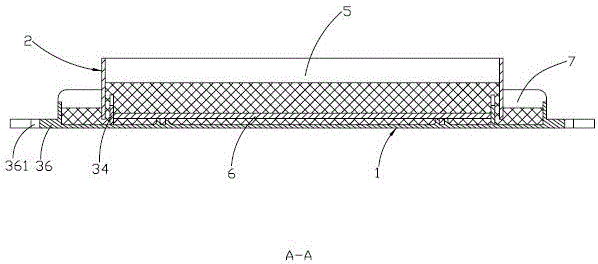

[0021] Such as figure 1 , 2 , 3, the embodiment of the present invention provides an increased safety glue filling drive box, including an upper cover 1, a surrounding shell 2 and a bottom shell 3, the surrounding shell 2 is a through hollow frame structure, the surrounding shell 2 Including a first open end 21 and a second open end 22 oppositely arranged, the bottom shell 3 is a frame structure with one end closed and one end open, the bottom shell 3 includes a bottom plate 31 and four side plates vertically connected to the bottom plate 31 32. The first opening end 21 of the surrounding shell 2 is sealed with the upper cover 1, and the second opening end 22 of the surrounding shell 2 is fixedly connected with the bottom plate 31 of the bottom shell 3. There are several bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com