The glue filling process of the increased safety glue filling drive box, the increased safety glue filling drive box and the lamp

A driving box and glue filling technology, which is applied to the safety devices of lighting devices, lighting and heating equipment, lighting devices, etc., can solve the problems of complex manufacturing process, low compatibility, poor reliability, etc., so as to save glue filling costs and save The effect of manufacturing cost and reducing the amount of glue poured

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

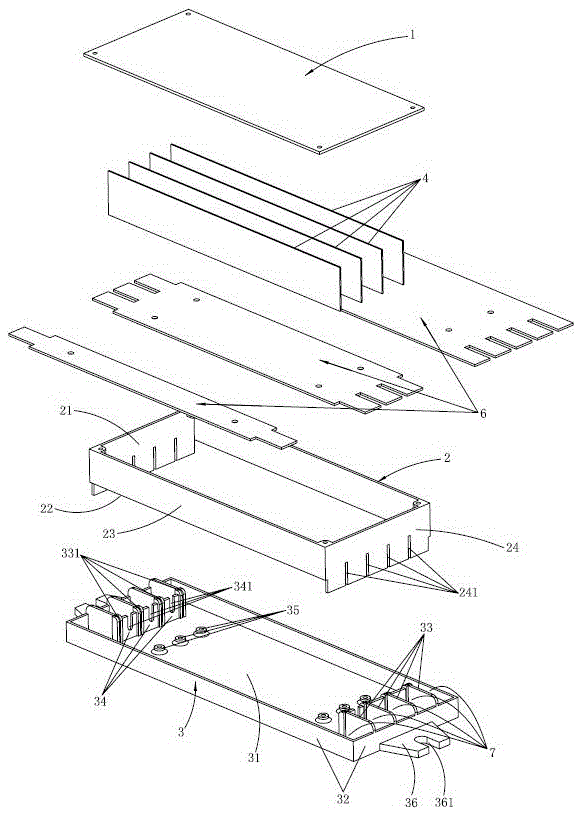

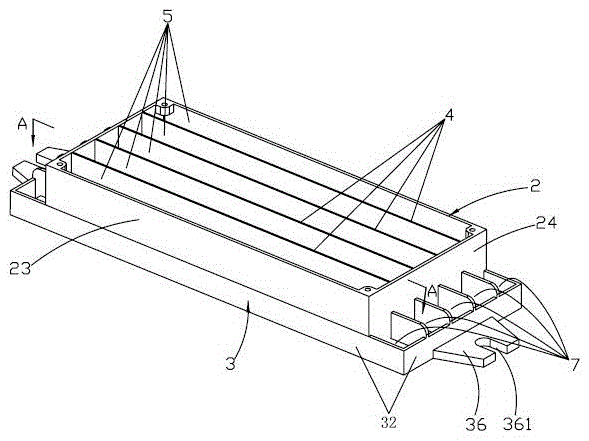

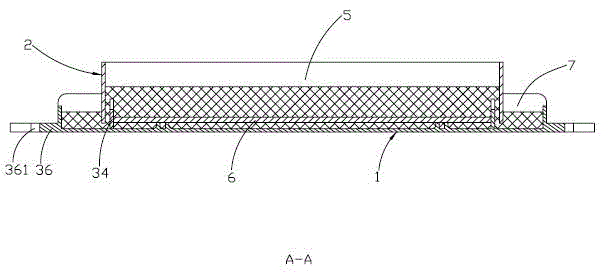

[0026] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the drawings in the embodiments of the present invention.

[0027] Such as figure 1 , 2 , 3, the embodiment of the present invention provides a kind of glue-filling process of increasing safety glue-filling drive box, comprising the following steps:

[0028] (1) A number of driver board glue tanks 5 and wiring glue tanks 7 that are independent of each other are set on the drive box. The wiring glue tanks 7 are located on both sides of the driver board glue tank 5 . A plurality of partitions 4 plugged into the drive box are formed;

[0029] (2) Install the driving board 6 in the glue filling groove 5 of the driving board, and install the wiring of the driving board 6 in the glue filling groove 7;

[0030] (3) Glue the wiring glue tank 7;

[0031] (4) Fill glue into the glue groove 5 of the drive board.

[0032] When the glue is pou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com