Method for supplying oxygen to hydrocarbon oil

A technology of hydrocarbon oil and oxygen supplementation, which is applied in the direction of refining with oxygen-containing compounds, etc., can solve the problems of low mercaptan efficiency and inability to convert mercaptans well, and achieve convenient operation, increased effective oxygen content, and simple process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

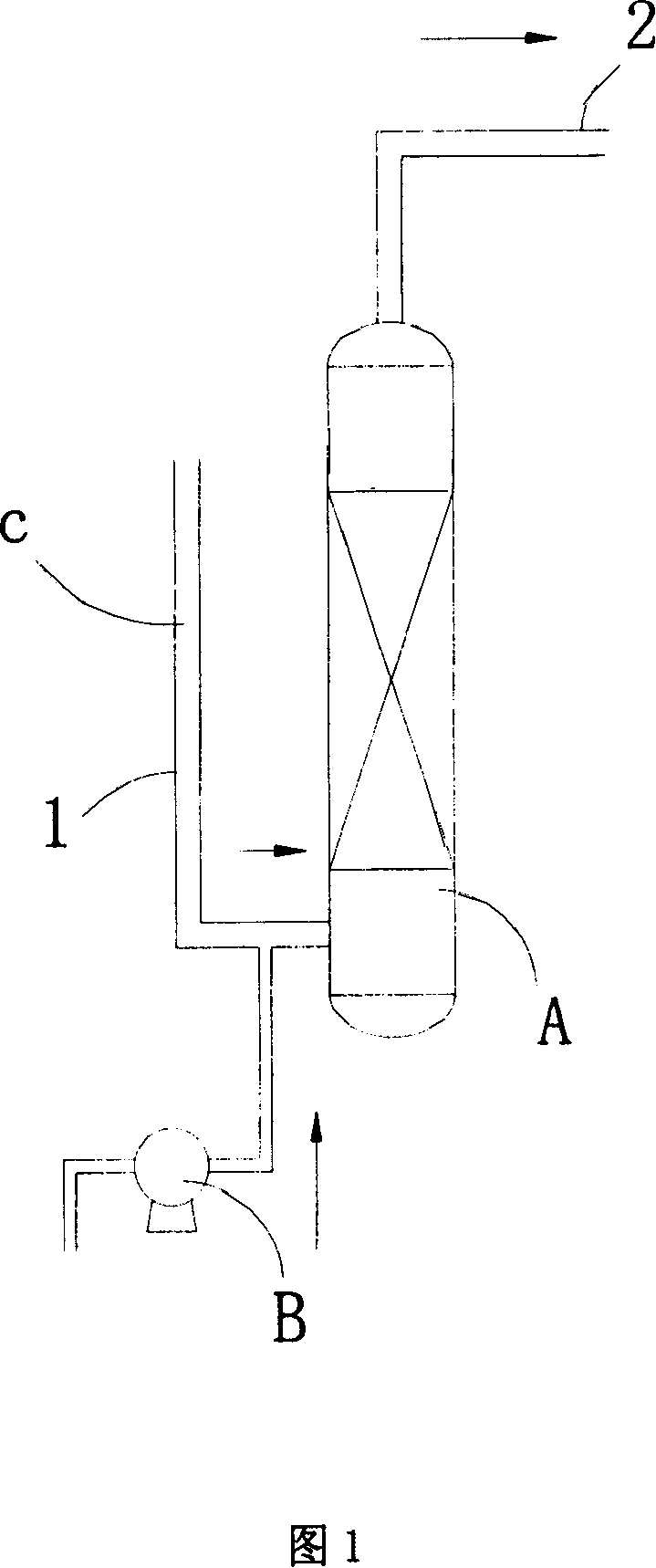

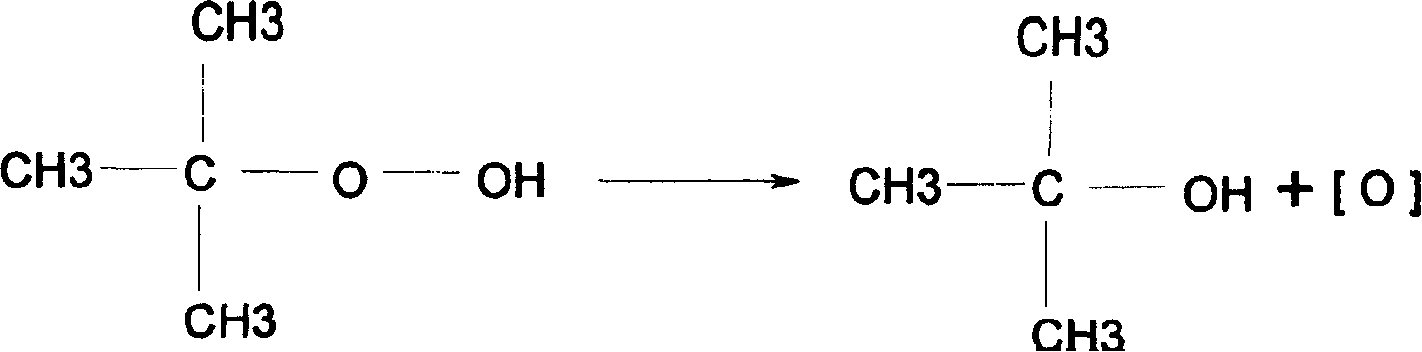

Method used

Image

Examples

manufacture example 1 to manufacture example 3

[0032] Cylindrical catalyst A1 whose active component is manganese dioxide, the catalyst A1 is entirely composed of manganese dioxide. The manufacturing method is as follows: Each manufacturing example takes a certain weight of powdered manganese dioxide respectively, and uses a tablet machine or a tablet press to press the powdered manganese dioxide under corresponding pressure into a cylindrical shape with a certain lateral pressure strength. The finished catalyst A11 of Production Example 1, the finished catalyst A12 of Production Example 2, and the finished catalyst A13 of Production Example 3 were obtained respectively. The diameters of these finished catalysts are all 6.5 mm, and the heights are all 6.2 mm to 6.5 mm. See Table 1 for the relevant parameters of the specifications and properties of the catalysts of each manufacturing example. In Manufacturing Example 1 to Manufacturing Example 3, the manufacturers of the powdery manganese dioxide used in different manufact...

manufacture example 4 to manufacture example 6

[0034]Cylindrical catalyst A2 whose active component is manganese carbonate, the catalyst A2 is entirely composed of manganese carbonate. The manufacturing method is as follows: Each manufacturing example weighs a certain weight of powdered manganese carbonate respectively, and presses the powdered manganese carbonate under corresponding pressure into a cylindrical solid with a certain lateral pressure strength by using a tablet machine or a tablet press. The finished catalyst product A21 of Production Example 4, the finished catalyst product A22 of Production Example 5, and the finished catalyst product A23 of Production Example 6 were respectively obtained from the molded products. The diameters of these finished catalysts are all 6.5 mm, and the heights are all 6.2 mm to 6.5 mm. See Table 1 for the relevant parameters of the specifications and properties of the catalysts of each manufacturing example. In manufacturing example 4 to manufacturing example 6, the manufacturers...

manufacture example 7 to manufacture example 9

[0036] Cylindrical catalyst A3 whose active component is trimanganese tetraoxide, the catalyst A3 is entirely composed of trimanganese tetraoxide. The manufacturing method is as follows: Each manufacturing example weighs a certain weight of powdered trimanganese tetroxide, respectively, and presses the powdered trimanganese tetraoxide under corresponding pressure with a tablet machine or a tablet press to form a tablet with a certain lateral pressure strength. The finished catalyst A31 of Production Example 7, the finished catalyst A32 of Production Example 8, and the finished catalyst A33 of Production Example 9 were respectively obtained as cylindrical solid moldings. The diameters of these finished catalysts are all 6.5 mm, and the heights are all 6.2 mm to 6.5 mm. See Table 1 for the relevant parameters of the specifications and properties of the catalysts of each manufacturing example. In Manufacturing Example 7 to Manufacturing Example 9, the manufacturers of the powder...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com