Hydrogen sulfide selective oxidation catalyst and preparation method thereof

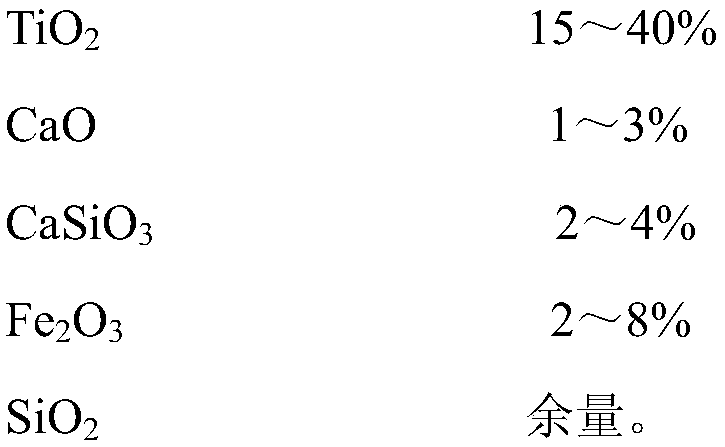

A selective oxidation and catalyst technology, applied in catalyst activation/preparation, physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, etc. It can solve problems such as poor performance, achieve significant economic and social benefits, high H2S conversion rate, and improve the effect of sulfur recovery rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

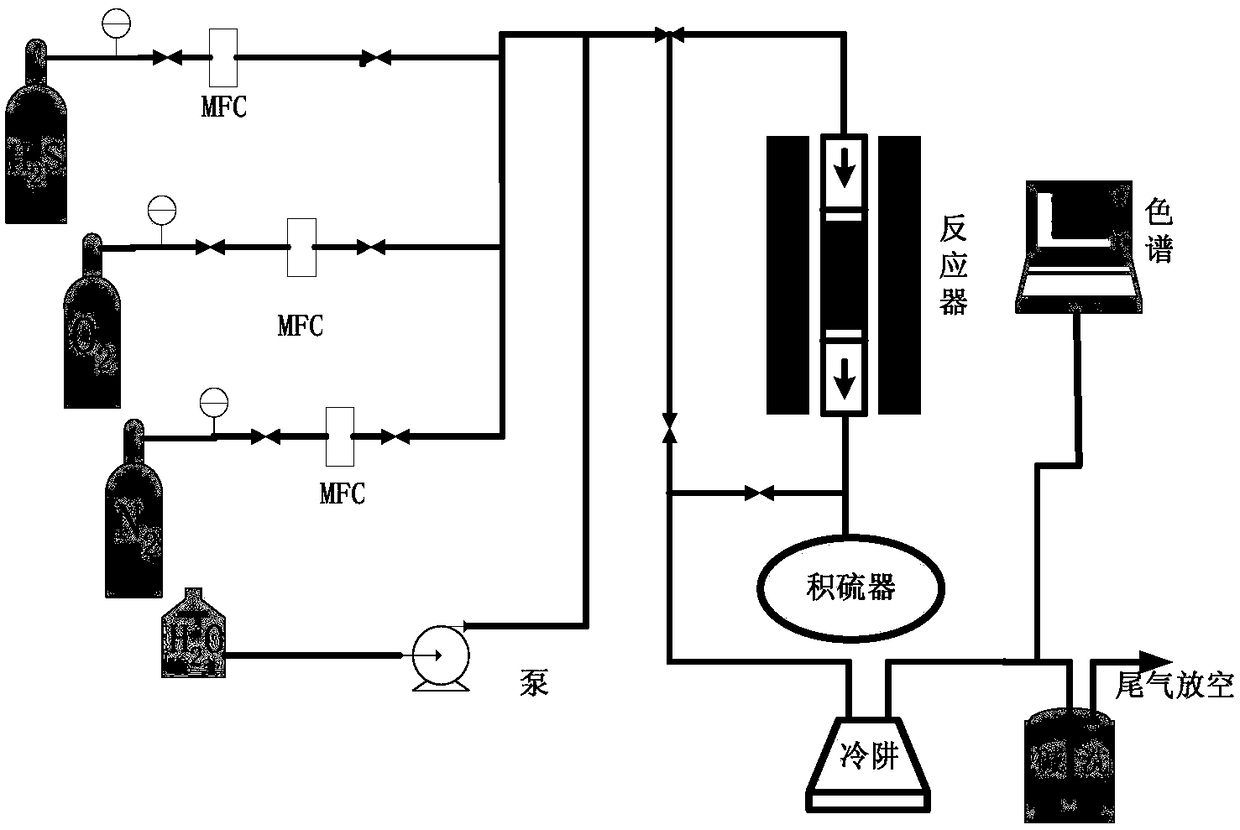

Method used

Image

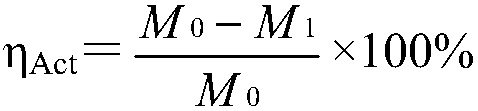

Examples

Embodiment 1

[0039] Weigh 650.6 grams specific surface is 50m 2 / g fumed silica powder (silicon oxide content is 99.9%), 312.5 grams of anatase metatitanic acid with a purity of 98%, 20.2 grams of calcium oxide with a purity of 99%, 30 grams of calcium silicate, 30 grams Sesame powder, mixed evenly to form material A. Mix 50 grams of concentrated nitric acid with 1300 grams of distilled water evenly, add to material A, extrude on an extruder, dry at 120°C for 4 hours, and roast at 700°C for 4 hours. The carrier thus obtained is Bar shape, the specific surface area of the carrier is 38m 2 / g, the pore volume is 0.66ml / g, and the average pore diameter is 41nm.

[0040] 305 grams of ferric ammonium citrate (FeC 6 h 5 o 7 .NH 4 OH) was added to 1200 grams of water, mixed evenly, and the obtained carrier was impregnated with the obtained solution for 1 hour, dried at 120°C for 4 hours, and calcined at 500°C for 4 hours. Surface area is 32m 2 / g, the pore volume is 0.62ml / g, and the a...

Embodiment 2

[0042] Weigh 500.6 grams specific surface is 40m 2 99% calcium oxide, 30 grams of calcium silicate, 30 Gram safflower powder, mix evenly to form material A. Mix 50 grams of concentrated nitric acid with 1100 grams of distilled water evenly, add it to material A, extrude it on an extruder, dry it at 120°C for 4 hours, and roast it at 700°C for 4 hours. The carrier thus obtained is Bar shape, the specific surface area of the carrier is 43m 2 / g, the pore volume is 0.64ml / g, and the average pore diameter is 39nm.

[0043] 305 grams of ferric ammonium citrate (FeC 6 h 5 o 7 .NH 4 OH) was added to 600 grams of water, mixed evenly, and the obtained carrier was impregnated with the obtained solution for 1 hour, dried at 120° C. for 4 hours, and calcined at 500° C. for 4 hours. Surface area is 36m 2 / g, the pore volume is 0.60ml / g, and the average pore diameter is 33nm.

Embodiment 3

[0045] Weigh 750.7 grams specific surface is 60m 2 / g fumed silica powder (silicon oxide content is 99.9%), 187.5 gram purity is 98% anatase metatitanic acid, 20.2 gram purity is 99% calcium oxide, 30 gram calcium silicate, 30 Gram safflower powder, mix evenly to form material A. Mix 50 grams of concentrated nitric acid with 1420 grams of distilled water evenly, add to material A, extrude on an extruder, dry at 120°C for 4 hours, and roast at 700°C for 4 hours. The carrier thus obtained is Bar shape, the specific surface area of the carrier is 31m 2 / g, the pore volume is 0.69ml / g, and the average pore diameter is 43nm.

[0046] 305 grams of ferric ammonium citrate (FeC 6 h 5 o 7 .NH 4 OH) was added to 600 grams of water, mixed evenly, and the obtained carrier was impregnated with the obtained solution for 1 hour, dried at 120° C. for 4 hours, and calcined at 500° C. for 4 hours. Surface area is 25m 2 / g, the pore volume is 0.65ml / g, and the average pore diameter is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com