Preparation method of TiO2/gamma-Al2O3 composite carrier material

A composite carrier and carrier technology, which is applied in the direction of catalyst carrier, chemical instrument and method, chemical/physical process, etc., can solve the problems of limited development and application, complicated preparation process, and few surface active sites, and achieve good hydrodesulfurization performance , The preparation method is simple, and the effect that meets the production needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Incorporation of 30wt% mesoporous TiO in aluminum sol 2 Whiskers (converted according to alumina dry material, with a diameter of 0.1-1μm, an aspect ratio of 2-20, and a specific surface area of 118m 2 / g, pore volume 0.39ml / g), add 15 times the dry weight (TiO 2 with Al 2 o 3 The sum of mass) of deionized water, mix well; heat to 80 ℃, drop HNO 3 Adjust the pH to 2 and keep it warm for 24 hours; add ammonia water dropwise to adjust the pH of the system to 9 to form Ti-Al-H 2 O composite jelly; after aging for 2 hours, wash with deionized water and filter until neutral, dry in the air, and put it into a muffle furnace for roasting at 500°C to obtain TiO 2 TiO with a whisker content of 30 wt% 2 / γ-Al 2 o 3 Composite carrier material.

[0020] The above-mentioned composite support material is impregnated with a molybdenum-nickel salt solution to prepare a molybdenum-nickel catalyst, wherein MoO 3 , NiO loadings were 30wt% and 7.8wt% of the mass of the catalyst,...

Embodiment 2

[0022] Add 2wt% sodium carboxymethylcellulose and 1wt% citric acid to the material in Example 1, filter and dry it, knead it evenly, extrude it, put it into a muffle furnace for roasting at 500°C, and obtain TiO 2 TiO with a whisker content of 30 wt% 2 / γ-Al 2 o 3 Composite molding carrier. The preparation and hydrodesulfurization performance of the catalyst were evaluated according to the conditions in Example 1.

[0023] The above-mentioned catalyst can reduce the sulfur content in FCC diesel with a sulfur content of 5600 μg / g to 48 μg / g.

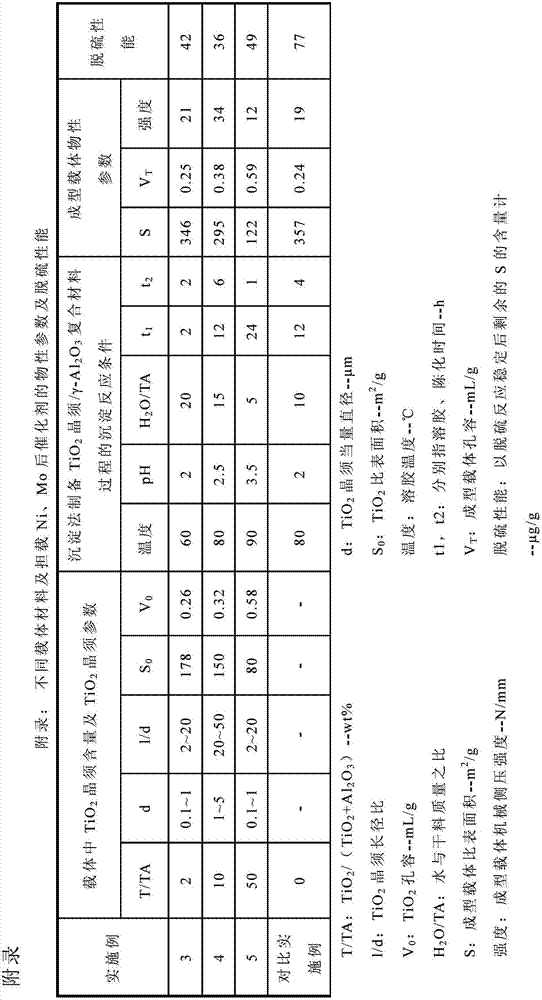

[0024] The preparation methods of Examples 3-5 and Comparative Examples are the same as those of Examples 1 and 2, and the parameters and performance evaluation of hydrodesulfurization are shown in the appendix.

[0025]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com