Triangular oblique surface type splash-proof denoising device

A technology of noise reducer and angled bevel, which is applied in the direction of instruments, sounding equipment, water shower coolers, etc., can solve the problems of poor processability and stability of processing and assembly, and it is difficult to connect the holes accurately and correctly, so as to achieve anti-corrosion The side water pressure capacity is strong, the side compressive strength is enhanced, and the effect of preventing slipping and falling defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

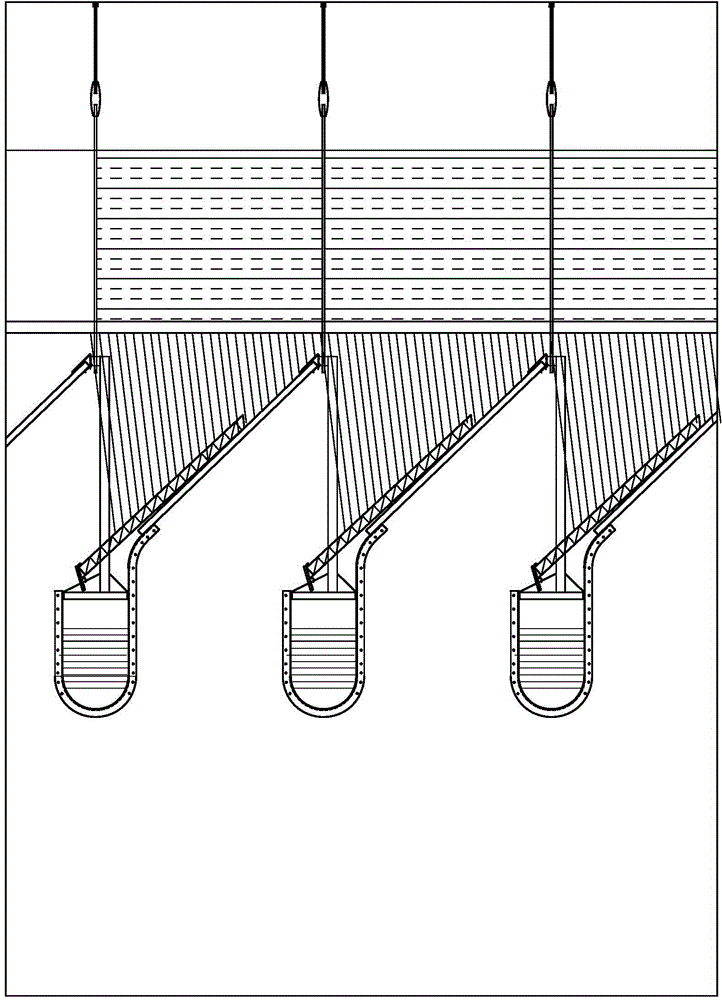

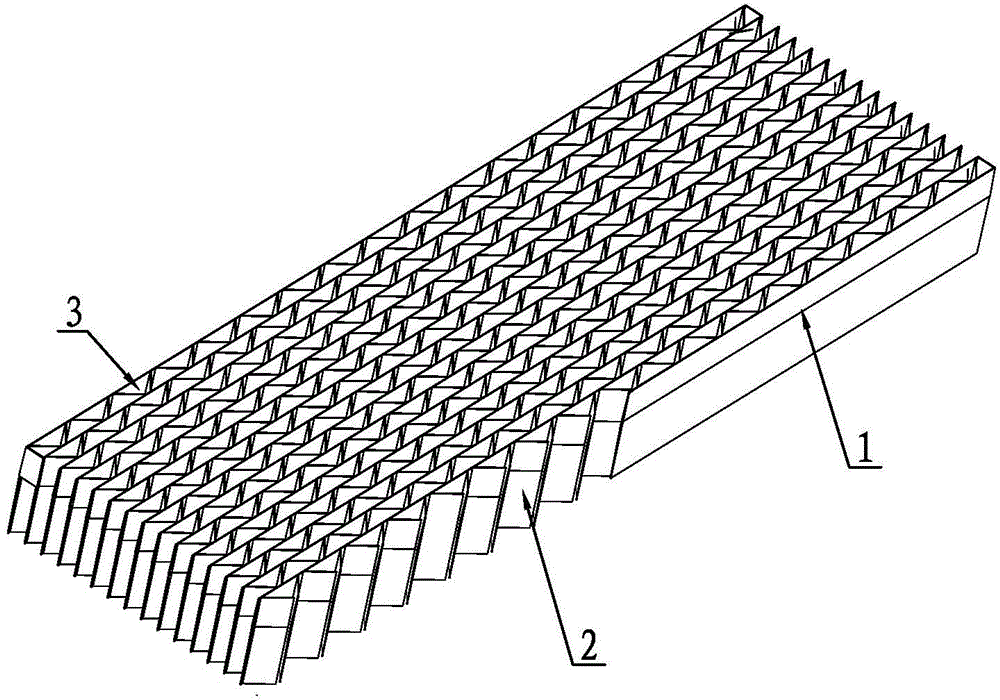

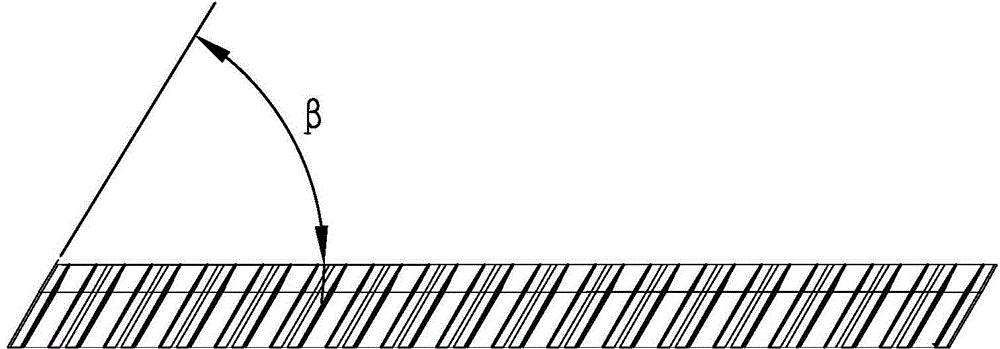

[0023] Embodiment 1: A kind of triangular slope noise reduction anti-splash noise reducer, such as Figure 2 to Figure 5 As shown, it is composed of a partition 1 and a triangular corrugated plate 2, the partition 1 and the triangular corrugated plate 2 are distributed at intervals, and a uniformly distributed triangular water chamber 3 is formed between the partition 1 and the triangular corrugated plate 2, and the triangular The inclination angle β between the center of gravity axis of the water-holding chamber 3 and the horizontal plane is 60°, the cross-sectional shape of the triangular water-holding chamber 3 is an equilateral triangle, and the triangular water-holding chamber 3 is provided with draft angles at both ends. The longitudinal cross-sectional shape of the plate 1 is small at both ends and large in the middle, the wall thickness of the top 11 of the partition is 1.0mm, the wall thickness of the boundary 12 of the partition is 2.5mm, the wall thickness of the bot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com