Road roadbed structure

A subgrade and road technology, applied in roads, roads, buildings, etc., can solve the problems of easy detachment of multi-layer lime soil layers, lateral compression resistance and poor resistance to soil erosion, so as to prevent water and soil erosion, enhance structural strength, enhance The effect of binding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the accompanying drawings.

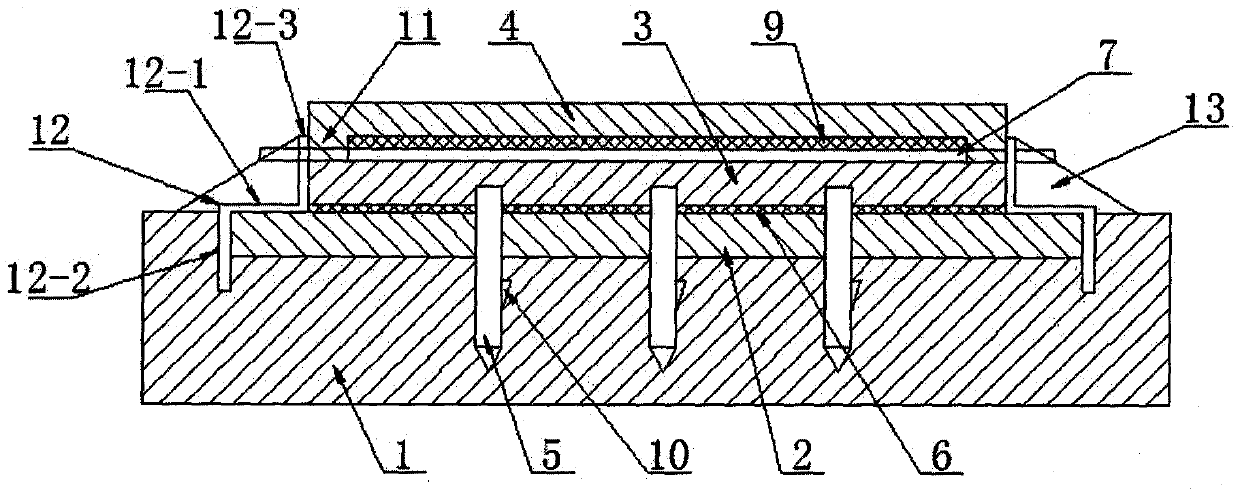

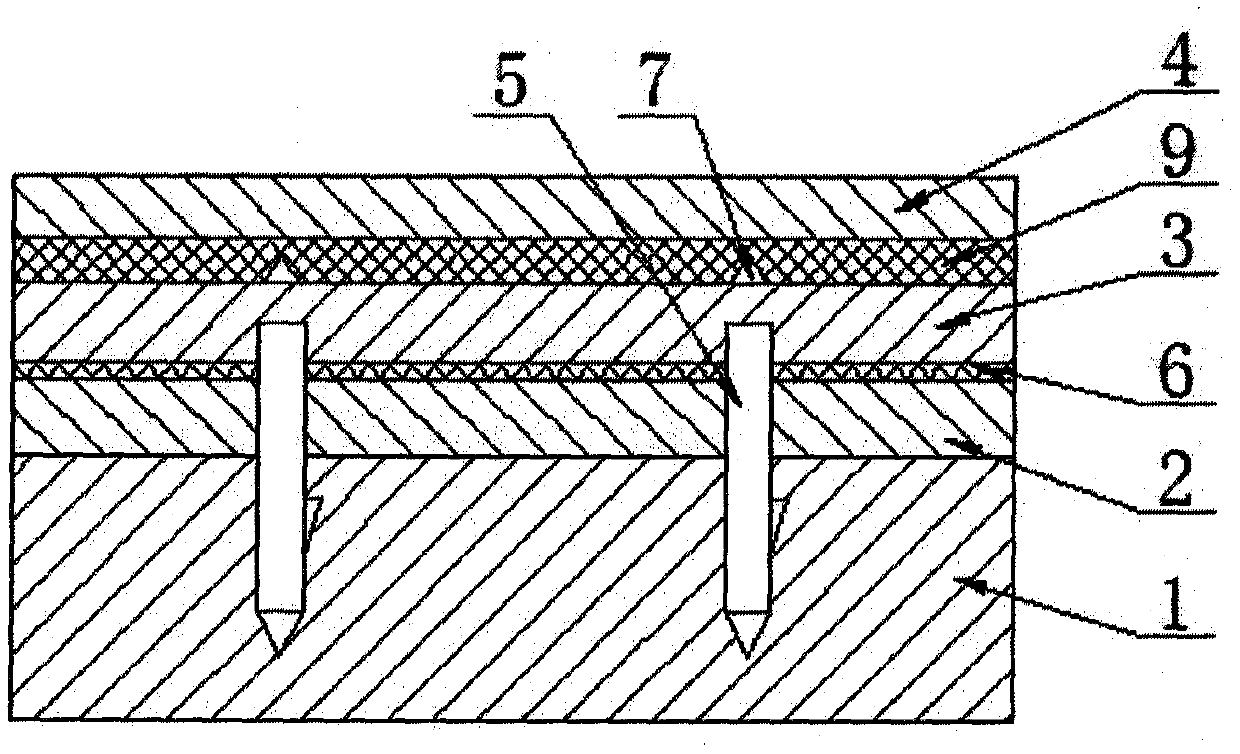

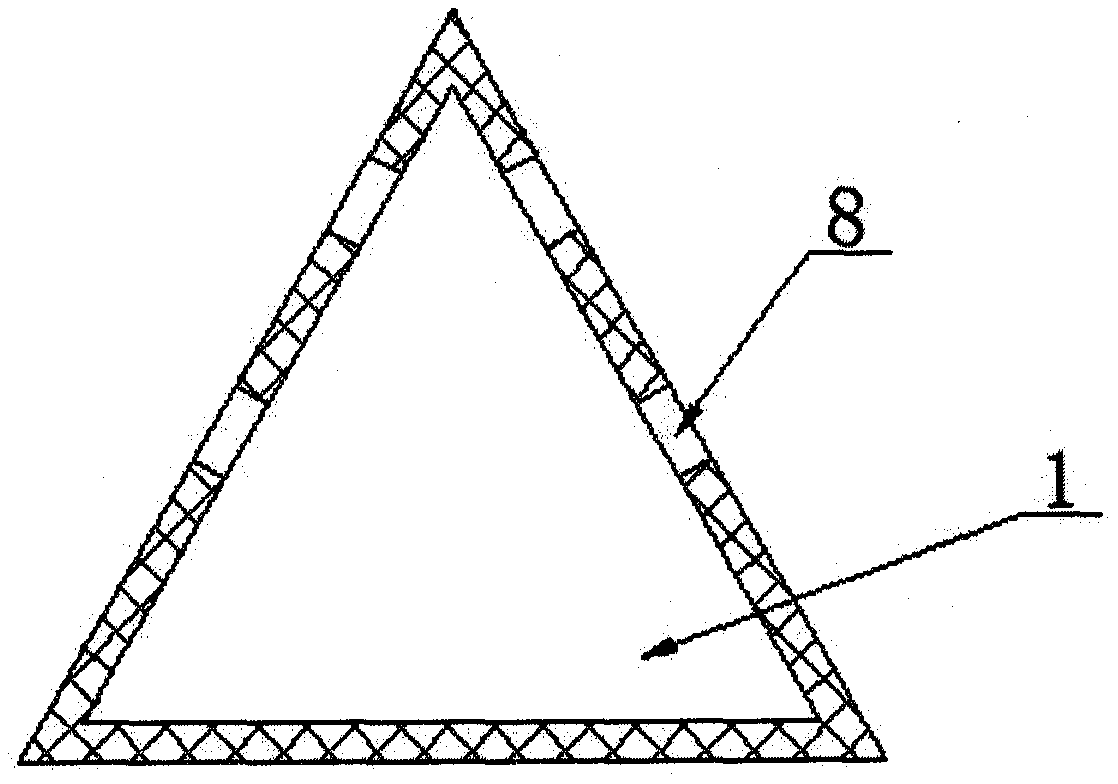

[0025] see as Figure 1-Figure 5 As shown, the specific embodiment includes a foundation 1, a first lime soil layer 2, a second lime soil layer 3, and a stable gravel layer 4, wherein the first lime soil layer 2 is laid on the foundation 1, and the first lime soil layer 2 is laid with the second lime soil layer. Lime soil layer 3, the second lime soil layer 3 is paved with crushed stone stable layer 4, and the crushed stone stable layer 4 is laid with surface course; Described first lime soil layer 2 is inserted with holding pile 5, holding pile The lower end of 5 passes through the first lime soil layer 2 and is inserted in the foundation 1, the upper end of the holding pile 5 is exposed above the first lime soil layer 2, and the first lime soil layer 2 and the second lime soil layer 3 are interposed There is a reinforced net 6, which is set on the holding pile 5, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com