Article storage apparatus

A storage device and article technology, applied in the directions of packaging, transportation and packaging, rigid containers, etc., can solve the problem that article storage devices cannot be stacked in high density.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0099] The best mode for carrying out the present invention will be described below while referring to the accompanying drawings.

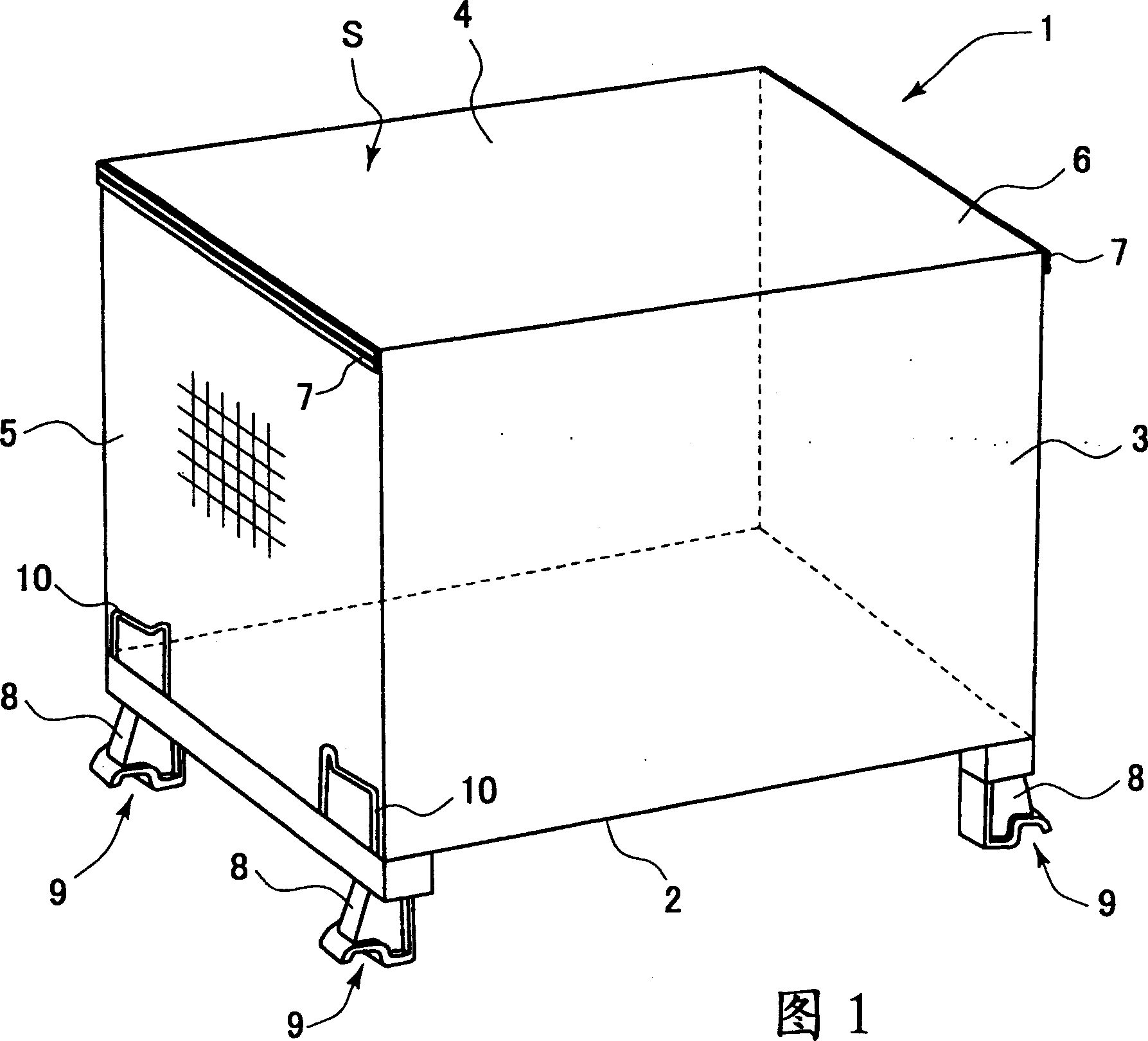

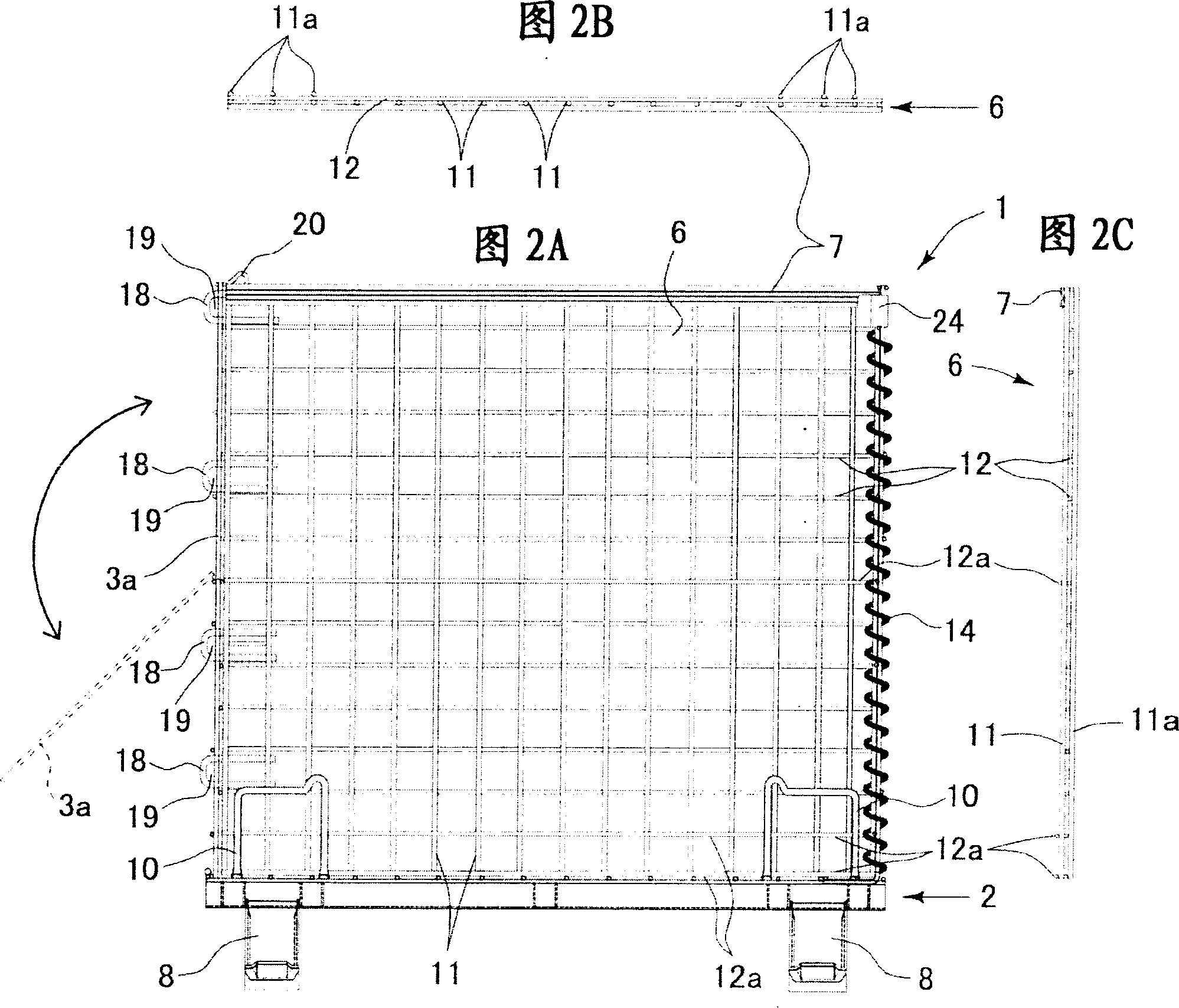

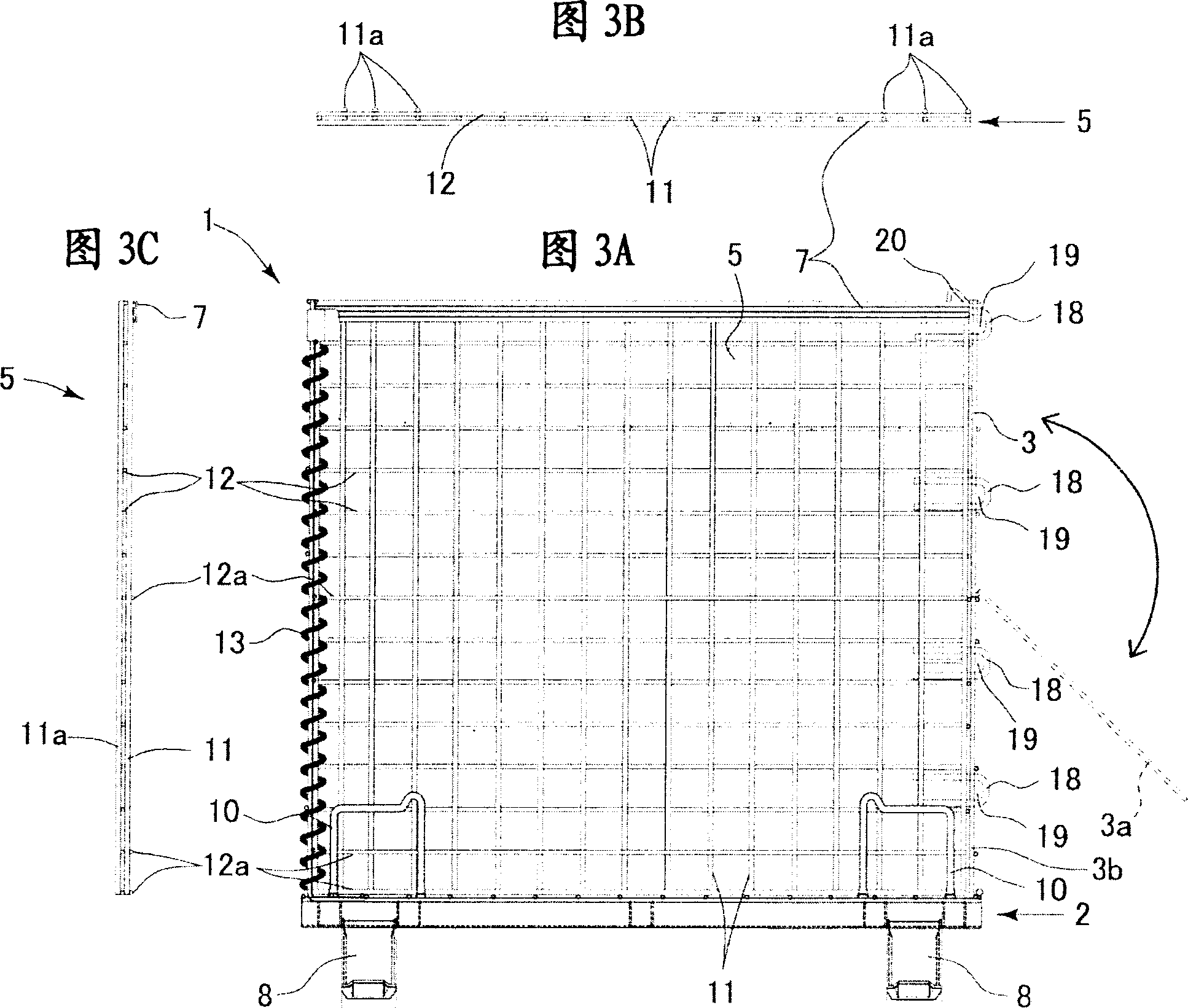

[0100] Figure 1 is a schematic perspective view of an object storage device 1 according to the invention. The article storage device 1 has a bottom lattice plate 2 (an example of a bottom plate), a front lattice plate 3 and a rear lattice plate 4 erected from the front and rear ends of the bottom lattice plate 2, and side lattices. Plates 5 and 6. In addition, an article storage space S is formed which is surrounded by each lattice-shaped plate 2-6 and opened to the upper side. In addition, the upper reinforcing member 7 is connected to the side surfaces of the side lattice panels 5 and 6 along the upper end of the panel. The reinforcing member 7 is obtained by forming using a metal plate or the like, and has a higher flexural strength than the bar-shaped members constituting each lattice-shaped plate 2-6. Further, leg portions 8 are provided i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com