A quasi-three-dimensional reinforced composite lattice sandwich structure and its manufacturing method

A sandwich structure and composite material technology, applied in the field of composite material structure, can solve problems such as weak surface-core bonding strength, achieve the effect of improving interface strength, improving mechanical properties, and improving mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

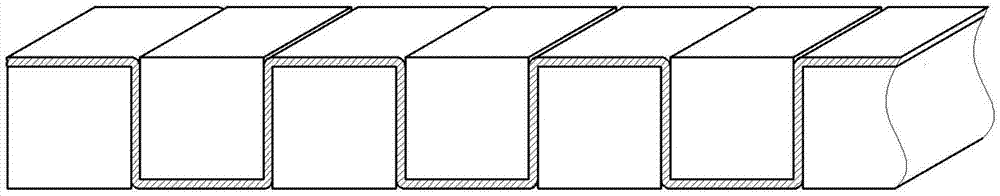

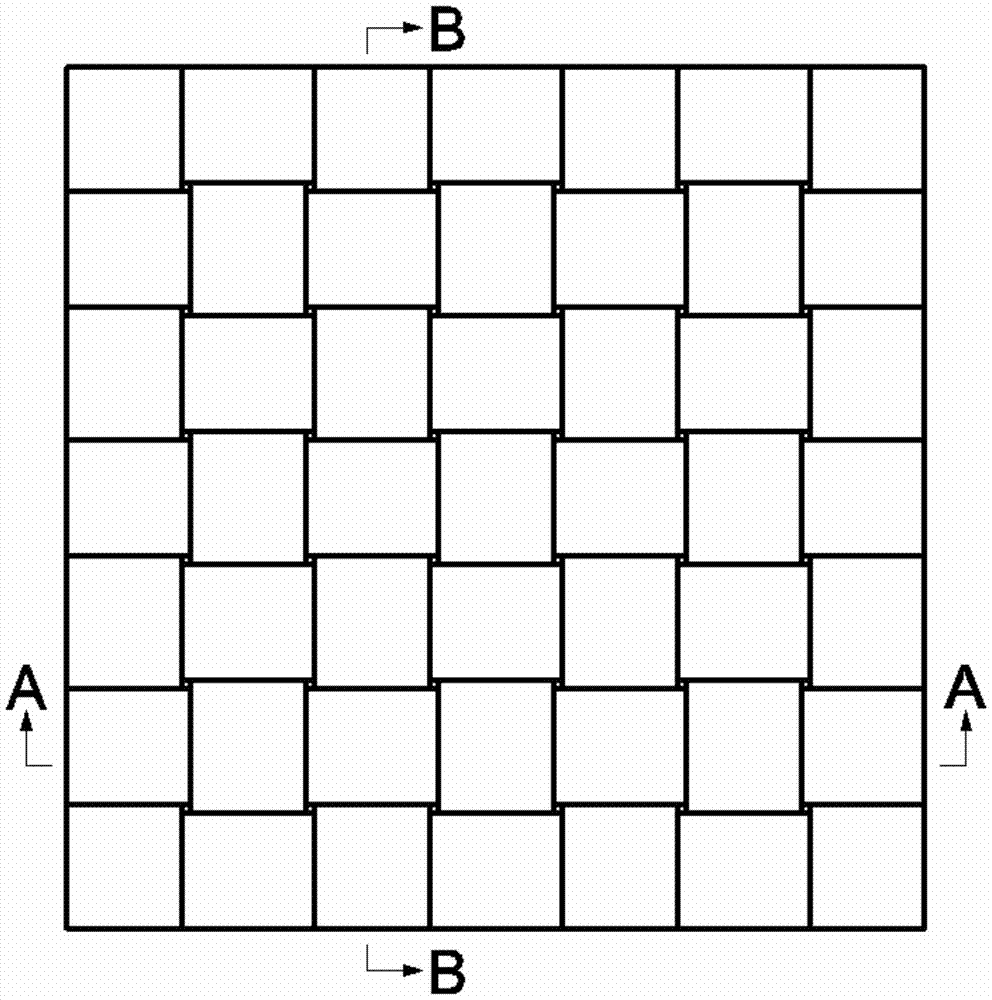

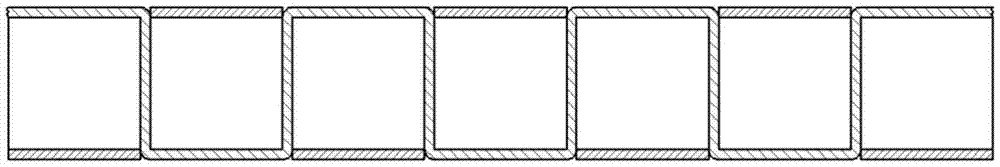

[0045] A quasi-three-dimensional reinforced composite material lattice sandwich structure, which is composed of fiber cloth and a woven lattice core. The woven lattice core is formed by interspersing and woven fiber cloth strips in an orthogonal manner. There is cubic foam as the core, the length of the quasi-three-dimensional reinforced composite lattice sandwich structure is [ml+xt(m-1)], and the structure width is [nl+xt(n-1)], The height of the structure is [2t(x+y)+l], where: m and n are the number of horizontal and vertical cube foams, l is the side length of the cube foam, and x and y are the lattice core and the panel ply. Number, t is the thickness of single-layer fiber cloth.

[0046] The fibers of the fiber cloth are glass fibers or carbon fibers.

Embodiment 2

[0048] A quasi-three-dimensional reinforced composite material lattice sandwich structure, which is composed of a prepreg and a braided lattice core. The braided lattice core is made of prepreg strips interspersed vertically and horizontally in an orthogonal manner. The prepreg There is a cubic foam between the strips as the core, the length of the structure is [ml+xt(m-1)], the width of the structure is [nl+xt(n-1)], and the height of the structure is [ 2t(x+y)+l], where: m and n are the number of horizontal and vertical cube foams, l is the side length of the cube foam, x and y are the number of dot matrix cores and panels, and t is a single layer Thickness of prepreg.

[0049] The prepreg is glass fiber reinforced resin-based prepreg or carbon fiber reinforced resin-based prepreg.

Embodiment 3

[0051] A method for manufacturing a quasi-three-dimensional reinforced composite material lattice sandwich structure includes the following steps:

[0052] 1) Determine that the lattice sandwich structure is composed of m rows and n columns of cubic foam cores and fiber cloth strips and upper and lower panel fiber cloth. m and n are non-zero natural numbers, the number of core layers is x, and the panel is laid The number of layers is y; the thickness of the single-layer fiber cloth is t, the side length of the cubic foam core is l, the total length of the target lattice sandwich structure is [ml+xt(m-1)], and the total width is [nl+xt (n-1)], the height is [2t(x+y)+l];

[0053] 2) Cut the fiber cloth raw materials into rectangular strips with a width of l according to the target structure size. The length of the longitudinal fiber cloth strips is greater than (2m-1)l, and the length of the transverse strips is greater than (2n-1)l. The cut rectangular strips are stacked neatly; c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com