Catalyst for preparing maleic anhydride from n-butane through oxidation and preparation method thereof

A catalyst and n-butane technology, applied in the direction of catalyst activation/preparation, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of high compressive strength, low compressive strength, high wear rate, etc., and achieve lateral The effect of high compressive strength, low wear rate, and low loss rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

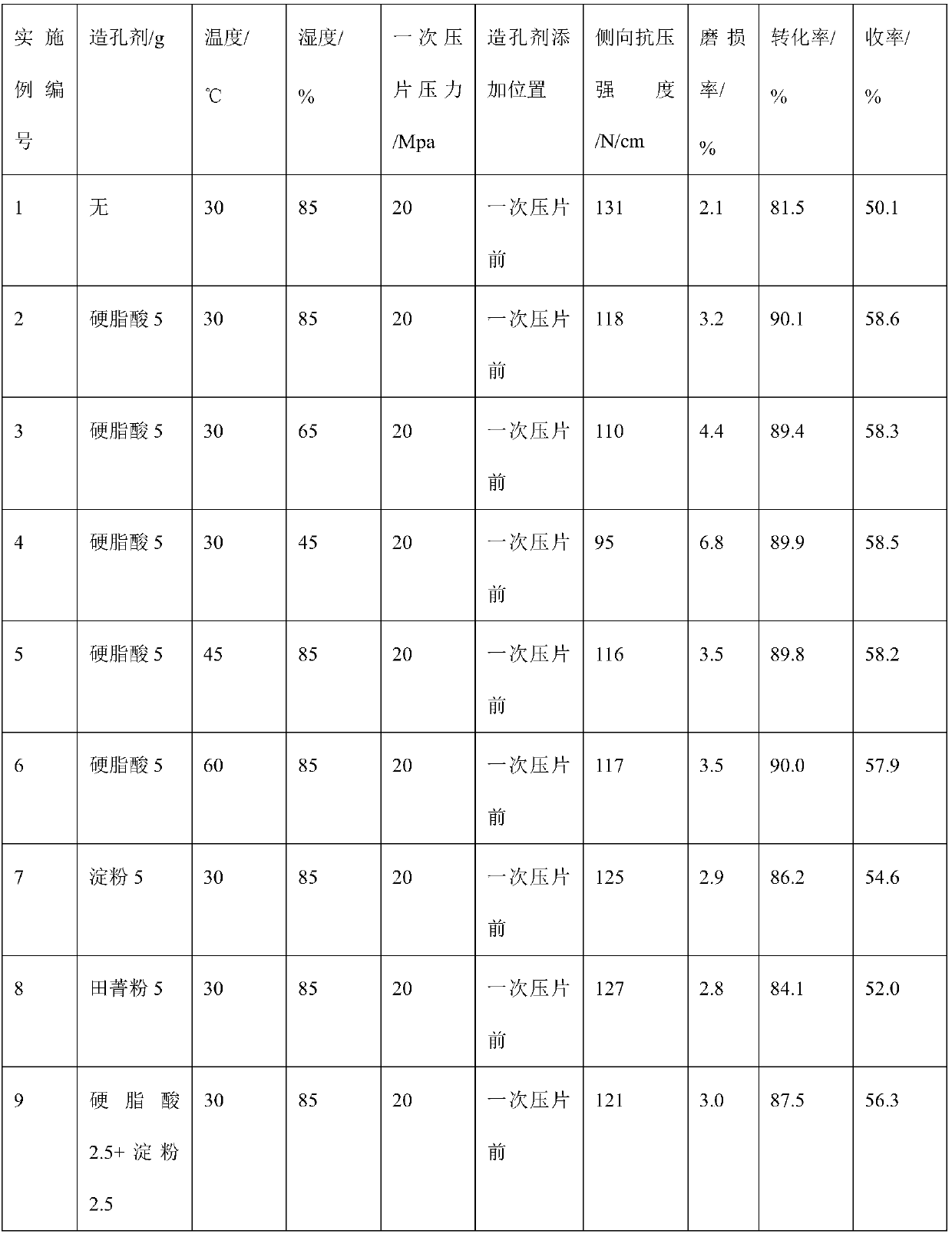

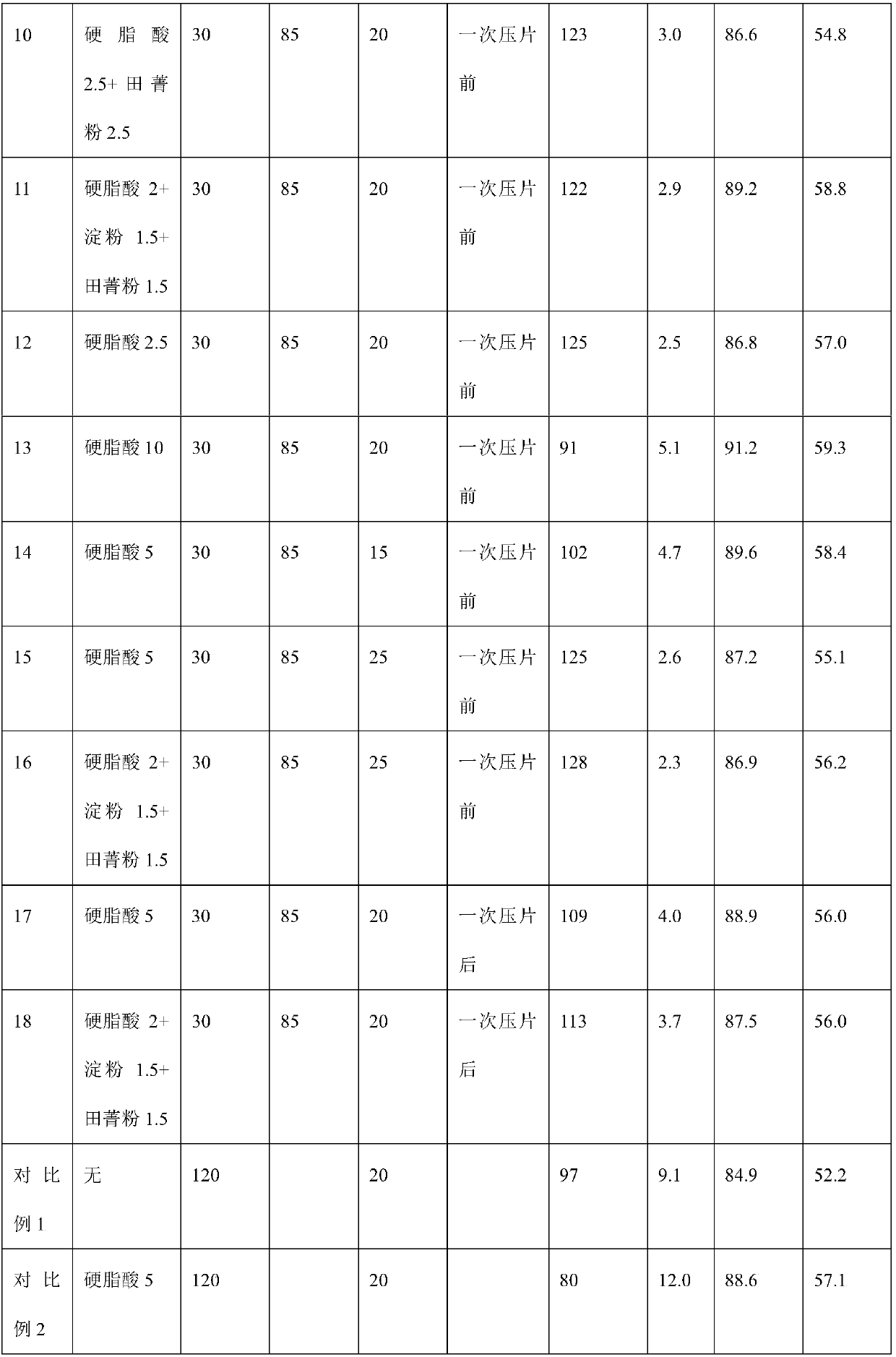

Embodiment 1

[0024] Mix 0.5g of phosphomolybdic acid with 100mL of benzyl alcohol and 400mL of isobutanol, then add 50.4g of vanadium pentoxide, then add 70mL of phosphoric acid, heat and reflux under constant stirring for 16 hours, filter and dry the resulting product to obtain a VPO catalyst precursor Powder, sieve the powdery catalyst precursor, take 50g of the precursor less than 200 mesh, and mix it well with 1.5g of graphite powder to form a mixture A; Treat in a wet oven for 12 hours; then compress the tablet under a pressure of 20 MPa to obtain a catalyst structure; then crush it, sieve it, and take the 80-140 mesh part; transfer the above-mentioned pre-granulated particles to a rotary tablet press, and the catalyst The height of the structure is 5mm, and the catalyst structure is obtained, the lateral compressive strength is 131N / cm, and the wear rate is 2.1%; the obtained catalyst is reacted with the butane raw material whose molar concentration is 1.5% mol, and the reaction proce...

Embodiment 2

[0026] Mix 0.5g of phosphomolybdic acid with 100mL of benzyl alcohol and 400mL of isobutanol, then add 50.4g of vanadium pentoxide, then add 70mL of phosphoric acid, heat and reflux under constant stirring for 16 hours, filter and dry the resulting product to obtain a VPO catalyst precursor Powder, sieve the powdery catalyst precursor, take 50g of the precursor less than 200 meshes, mix well with 1.5g graphite powder to form mixture A; ℃, and the relative humidity is 85% in a constant temperature and humidity oven for 12 hours; then press it under a pressure of 20MPa to obtain a one-time molded catalyst structure; The particles are transferred to the rotary tablet press, the height of the catalyst structure is 6mm, and the catalyst structure is obtained, the lateral compressive strength is 118N / cm, and the wear rate is 3.2%; Reaction, its reaction process conditions: 2000hr -1Space velocity and 400°C under normal pressure were evaluated in a fixed-bed reactor, and the convers...

Embodiment 3

[0028] Mix 0.5g of phosphomolybdic acid with 100mL of benzyl alcohol and 400mL of isobutanol, then add 50.4g of vanadium pentoxide, then add 70mL of phosphoric acid, heat and reflux under constant stirring for 16 hours, filter and dry the resulting product to obtain a VPO catalyst precursor Powder, sieve the powdery catalyst precursor, take 50g of the precursor less than 200 meshes, mix well with 1.5g graphite powder to form mixture A; ℃, with a relative humidity of 65% in a constant temperature and humidity oven for 12 hours; then press the tablet under a pressure of 20 MPa to obtain a one-time shaped catalyst structure; then crush it, sieve it, and take the 80-140 mesh part; The particles are transferred to the rotary tablet press, the height of the catalyst structure is 5mm, and the catalyst structure is obtained, the lateral compressive strength is 110N / cm, and the wear rate is 4.4%; Reaction, its reaction process conditions: 2000hr -1 Space velocity and 400°C under norma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com