Method for solidifying and stabilizing sludge

A sludge and dewatered sludge technology, applied in chemical instruments and methods, sludge treatment, water/sludge/sewage treatment, etc., can solve the problems of unfavorable utilization of landfills, high price of bentonite, obstacles to hydration reactions, etc. problem, to achieve the effect of enhanced lateral compressive strength, reduced leaching rate, and reduced capacity expansion ratio

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

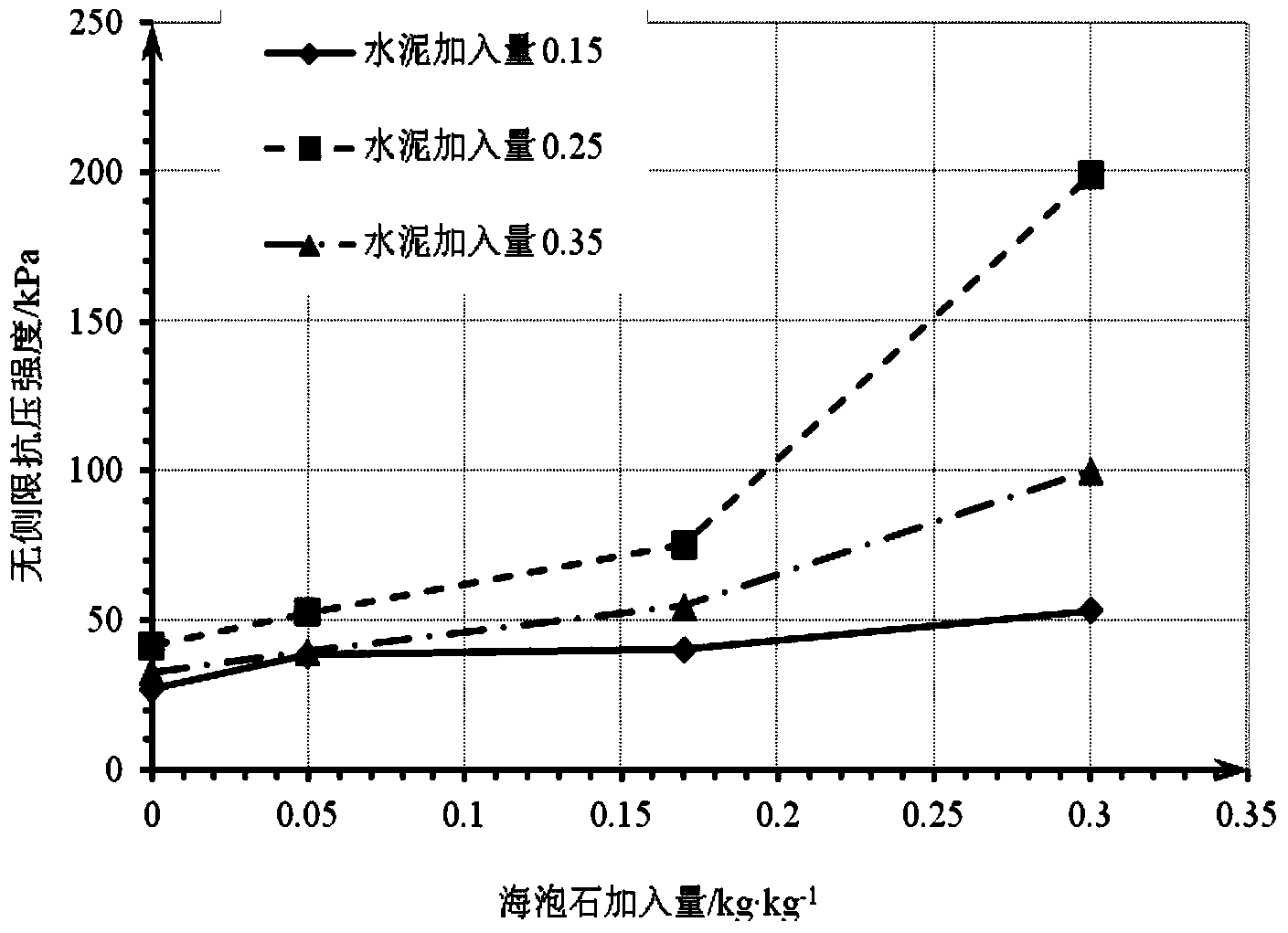

[0023] From figure 1 It can be seen that when the cement addition is 0.25kg / kg, the compressive strength of the solidified / stabilized sludge increases with the addition of sepiolite, and when the addition of sepiolite is 0.17kg / kg, the solidified sludge The strength of the mud is greater than 50kPa, which meets the requirements of the landfill plant; the addition of sepiolite is 0.3kg / kg, and the strength of the solidified sample reaches 100kPa, which meets the requirements of the building backfill. When the cement content is 0.35kg / kg, the effect of adding sepiolite to improve the strength of solidified sludge is very obvious. When the amount of sepiolite increases from 0 to 0.17kg / kg, the strength of solidified sludge rises from 32.7kPa to 54.8kPa, when the amount of sepiolite is 0.3kg / kg, the strength of solidifie...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com