Preparation method of aluminum oxide carrier

An alumina carrier, ionic liquid technology, applied in catalyst carriers, chemical instruments and methods, chemical/physical processes, etc., can solve the problems of amorphous pseudo-boehmite, sol aggregation into gel, uneven particle size distribution, etc. , to achieve the effect of large pore size and pore volume, improving comprehensive performance and high specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

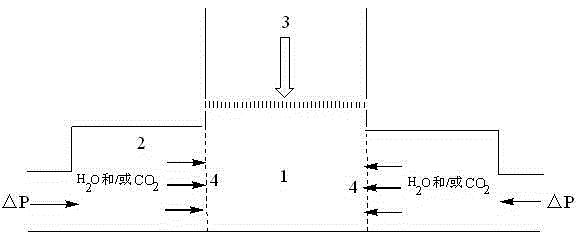

[0040] The preparation method of alumina carrier of the present invention comprises the following steps:

[0041] (a) The concentration and preparation method of the working solution are well known to those skilled in the art. For example, the concentration of an acidic aluminum salt solution is Al 2 o 3 It is calculated as 3g / 100mL~15g / 100mL; the concentration of alkali metal aluminum salt solution is expressed as Al 2 o 3 Calculated as 8g / 100mL~35g / 100mL, the alkali metal aluminum salt aqueous solution is selected from NaAlO 2 , KAlO 2 One or more in aqueous solution, preferably NaAlO 2 aqueous solution;

[0042] (b) by M 1 respectively and M 2 , M 3 Made into ionic liquids I and II;

[0043] (c) Add bottom water and a certain amount of ionic liquid I to the bottom of reactor 1, and heat to 25-45°C;

[0044] (d) Adjust the feeding speed of the feeding pipe on the reactor, and flow a certain concentration of alkaline metal salt solution into the reactor at a flow r...

Embodiment 1

[0052] 400g of triethylammonium chloride, 220g of sodium hexafluorophosphate, and 450g of pure water were mixed, heated to 90°C under stirring, kept at a constant temperature for 3 hours, clarified, naturally cooled to about 30°C, and centrifuged to filter out the solid to obtain 450g of ionic liquid I. The water content is about 3.5wt%, and the yield is 72wt%.

[0053] Trimethylphenylammonium chloride 500g, sodium hexafluorophosphate 260g, pure water 450g, mix, heat to 90°C under stirring, keep the temperature for 3 hours, clarify, naturally cool to about 30°C, centrifuge and filter out the solid to obtain the ionic liquid II 550g, water content about 3.5wt%, yield 74wt%.

[0054] 1L of bottom water and 40g of ionic liquid I were added to the bottom of reactor 1, and the reaction temperature was adjusted to 30°C. Regulate the feed rate of feed pipe on the reactor, the NaAlO that concentration is 10g / 100ml 2 The flow rate of the solution is 20ml / min and CO is injected at a f...

Embodiment 2

[0057] Triethylammonium chloride 300g, sodium hexafluorophosphate 160g, pure water 350g, mixed, heated to 100°C under stirring, kept at constant temperature for 2.5h, clarified, naturally cooled to about 30°C, centrifuged to filter out the solid to obtain 420g of ionic liquid I , the water content is about 3.7wt%, and the yield is 72wt%.

[0058] Dimethylphenylammonium chloride 600g, sodium tetrafluoroborate 300g, pure water 550g, mix, heat to 70°C under stirring, keep the temperature for 3 hours, clarify, naturally cool to about 30°C, centrifuge and filter out the solid to obtain the ionic liquid II 550g, water content about 4.0wt%, yield 74wt%.

[0059] Add 2L of bottom water and 35g of ionic liquid I to the bottom of reactor 1, and adjust the reaction temperature to 40°C. Regulate the feeding speed of feed pipe on the reactor, the NaAlO that concentration is 15g / 100ml 2 The flow rate of the solution is 25ml / min and CO is injected at a flow rate of 3.5L / min through the sem...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| crystallinity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com