Complex frequency emulsified fluid power sounding device

A sounding device and fluid power technology, applied in chemical instruments and methods, shaking/oscillating/vibrating mixers, dissolving, etc., to achieve the effects of high emulsification and mixing efficiency, easy vibration, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

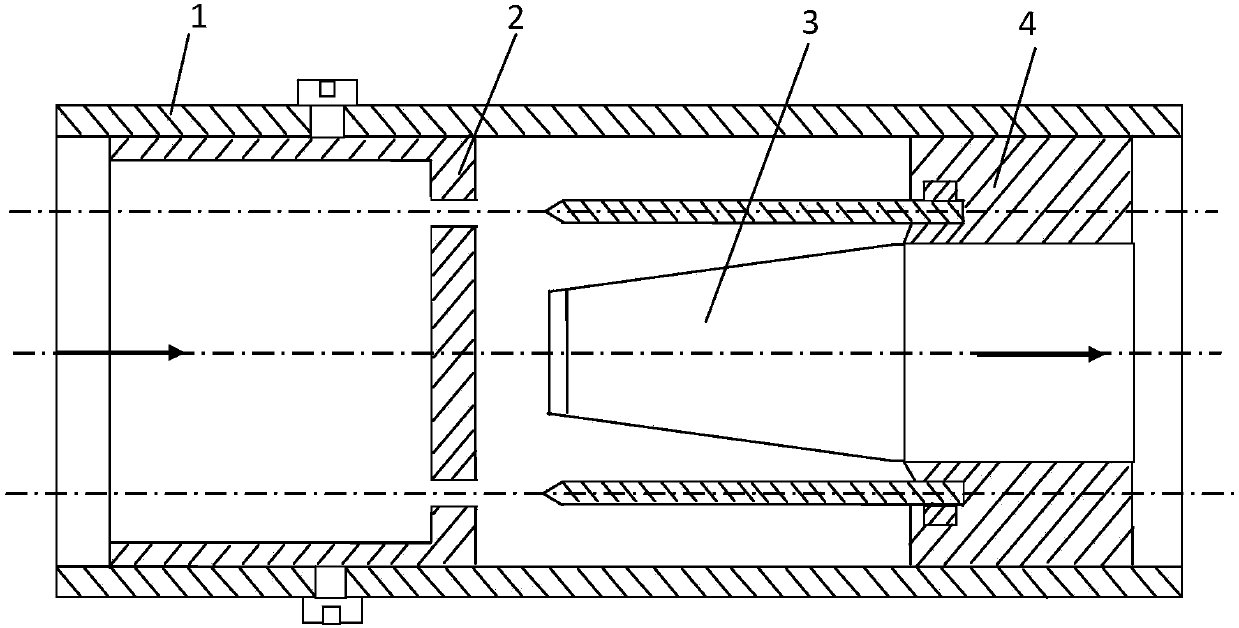

[0023] combine figure 1 It can be seen that the multiple-frequency emulsification hydrodynamic sound generating device of this embodiment is composed of the casing 1 , the nozzle 2 , the reed 3 and the bracket 4 .

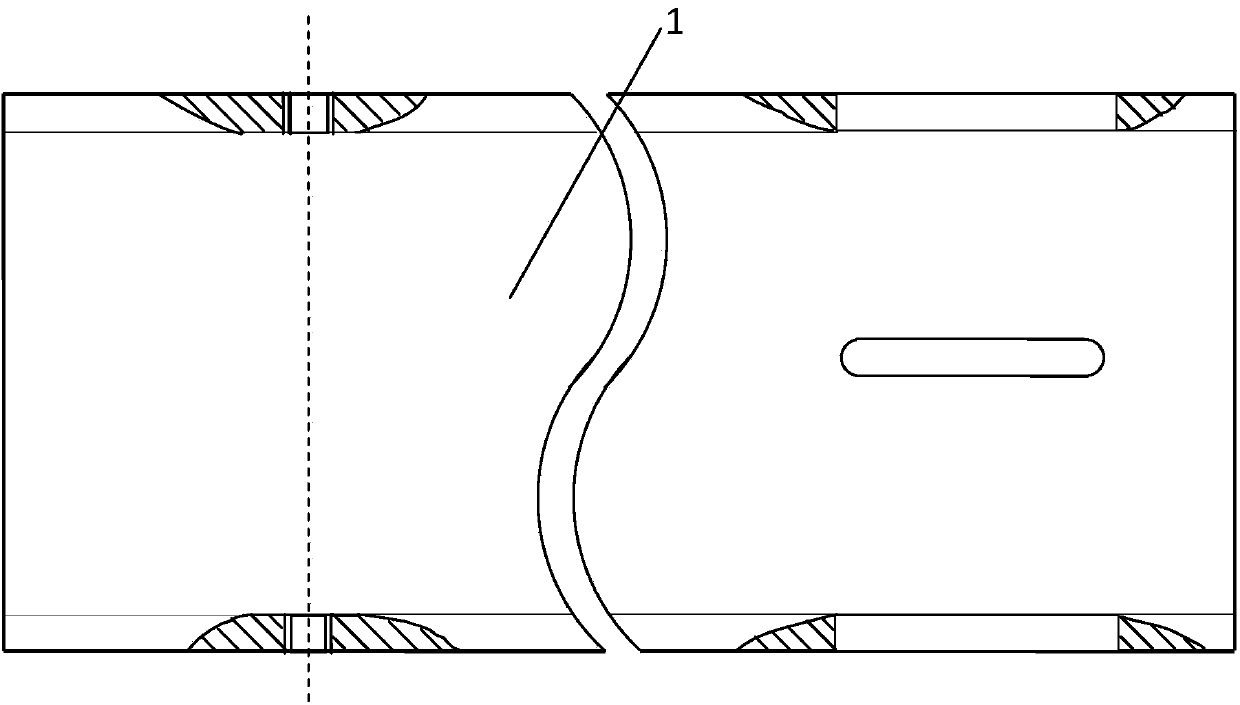

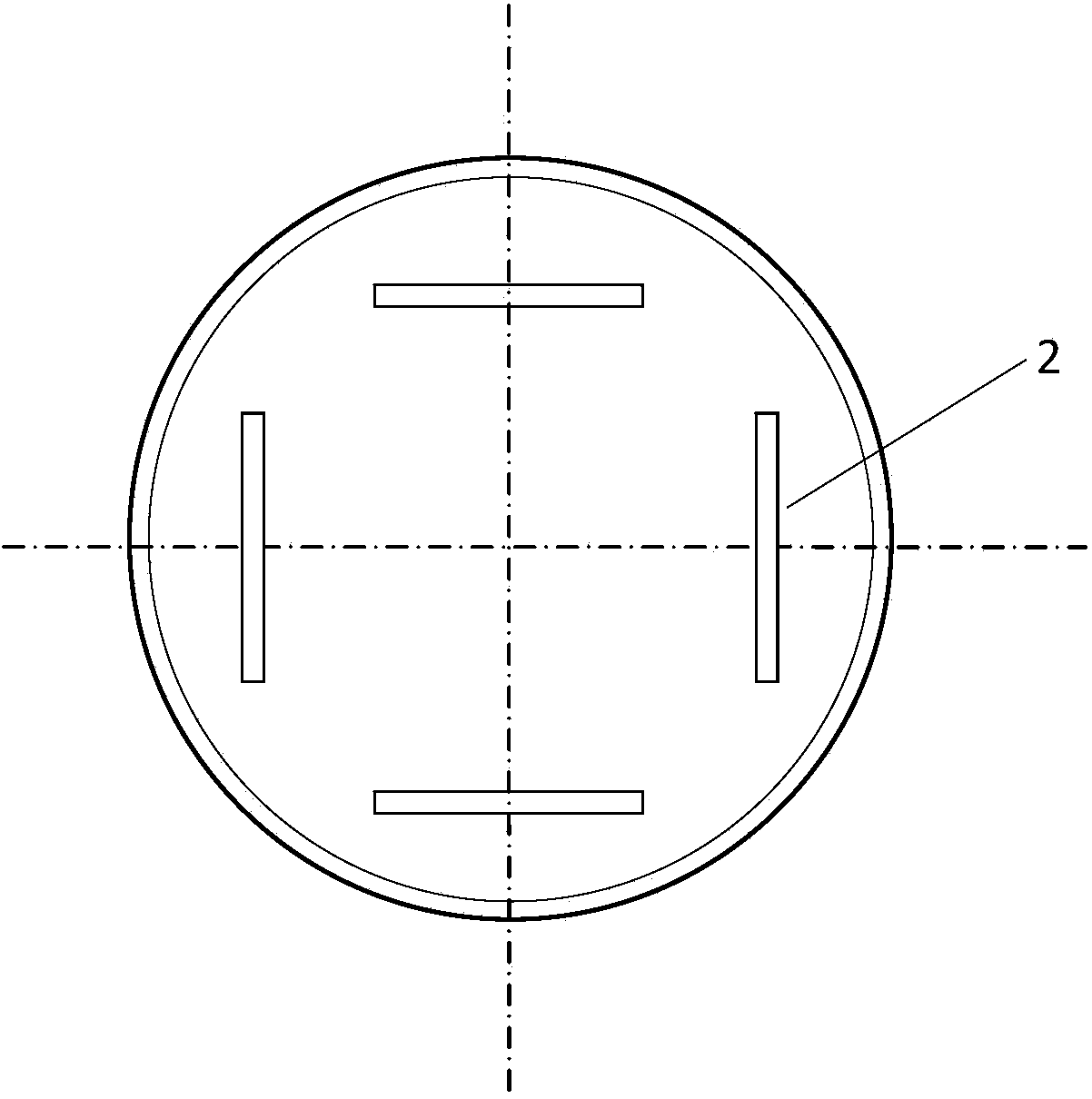

[0024] see figure 1 , the casing 1 of this embodiment is circular, and four symmetrically distributed positioning holes and two positioning grooves parallel to each other are processed on its side wall, and an internal thread is processed on the inner wall of the casing 1. Both ends have external threads for joining fittings or pipes. Nozzle 2 is installed in sleeve 1, see figure 2 On the outside of the side wall of the nozzle 2, an external thread matching the casing 1 is processed, and the pitch of the external thread is 4 mm. Two slot holes corresponding to the positioning groove of the casing 1 are also processed on the side wall of the nozzle 2. Tighten to realize the positioning of the nozzle 2 and the casing 1. Four rectangular nozzles are processed on t...

Embodiment 2

[0027] The end face of the nozzle 2 of this embodiment is processed with 4 rectangular nozzles, and the 4 rectangular nozzles are distributed in a regular quadrilateral on the nozzle 2. The flow channel section of each nozzle is tapered, and the length of the flow channel is 5mm. 10mm, 2mm wide rectangle. A circular bracket 4 is installed on the jet flow direction of the nozzle 2, and 4 concave surfaces are also processed on the side wall of the bracket 4 in the direction corresponding to the nozzle, and a reed 3 is fastened with a screw on each concave surface, and each spring The piece 3 is facing the nozzle, and its free end is 1mm away from the nozzle. The length and thickness of one reed 3 and the adjacent reed 3 are different, but the length and thickness of the two opposite reeds 3 are the same. A group of reeds The effective length of 3 is 20mm, and the thickness is 0.5mm. The effective length of an adjacent reed 3 is 22mm, and the thickness is 0.6mm.

[0028] Other c...

Embodiment 3

[0030] The end face of the nozzle 2 of this embodiment is processed with 4 rectangular spouts, and the 4 rectangular spouts are distributed in a regular quadrilateral on the nozzle 2. The flow passage section of each spout is streamlined, the flow passage length is 20mm, and its cross-sectional length is 20mm and a width of 1mm. A circular bracket 4 is installed on the jet flow direction of the nozzle 2, and 4 concave surfaces are also processed on the side wall of the bracket 4 in the direction corresponding to the nozzle, and a reed 3 is fastened with a screw on each concave surface, and each spring The piece 3 is facing the spout, and its free end is 6mm away from the spout. The length and thickness of one reed 3 and the adjacent reed 3 are different, but the length and thickness of the two reeds 3 arranged oppositely are the same. A group of reeds 3 The effective length of the reed is 50mm, and the thickness is 2mm, and the effective length of another group of reeds 3 is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com