Emulgator for producing nitro-sulfenyl slow-release fertilizer

A long-acting fertilizer, nitrosulfur-based technology, applied in chemical instruments and methods, applications, fertilization devices, etc., can solve problems such as low efficiency, uneven emulsification, poor emulsification effect, etc. The effect of emulsification efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

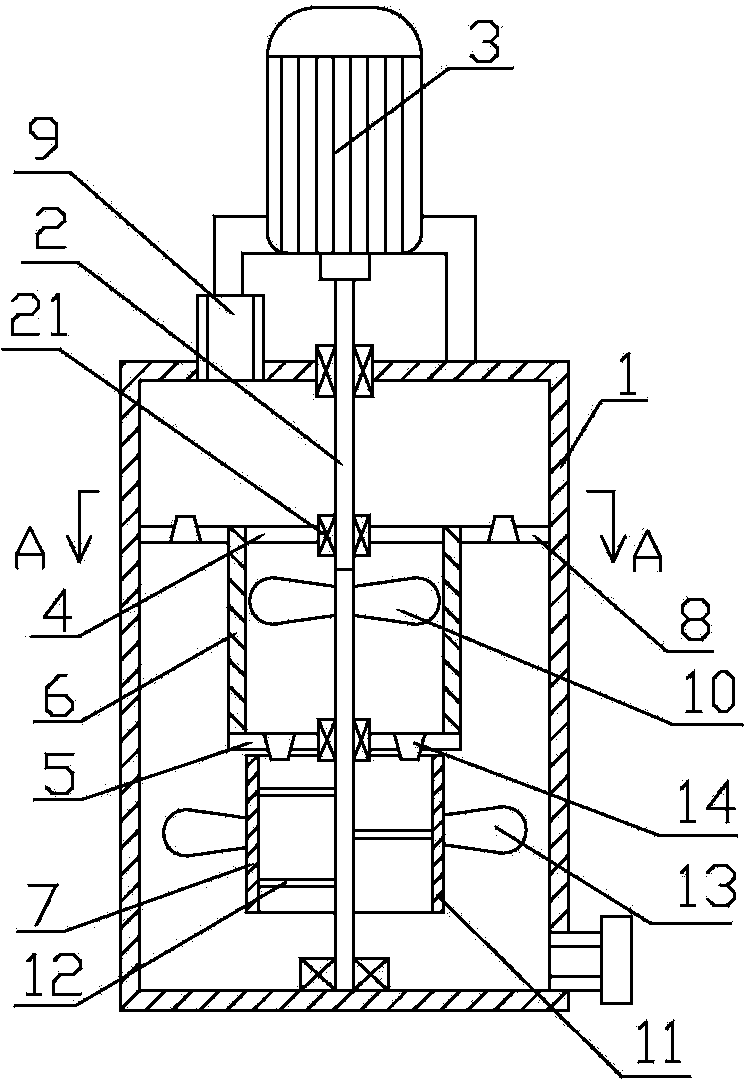

[0014] Such as figure 1 As shown, the emulsifier for the production of nitrosulfur-based long-acting fertilizer of the present invention comprises a housing 1 and a stirring shaft 2 arranged in the housing 1, the upper end of the housing 1 is provided with a feed inlet 9, and the The upper end of the stirring shaft 2 extends to the outside of the housing 1 and is connected to the motor 3 in transmission. When working, the mixed material is transported into the housing 1 through the feed port 9, and the motor 3 is used to drive the stirring shaft 2 to rotate to stir the material evenly to achieve the purpose of emulsification.

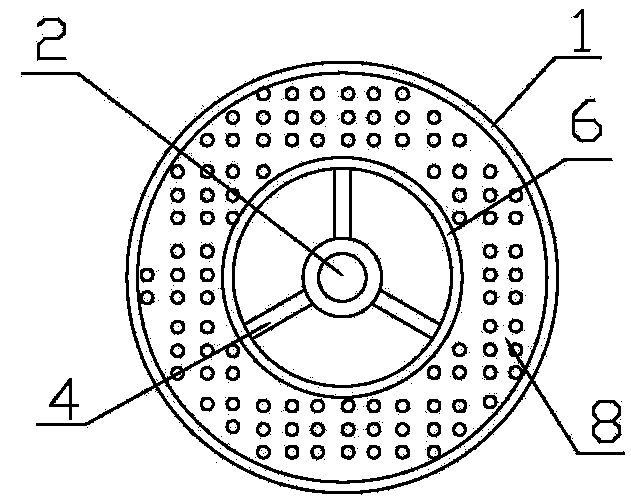

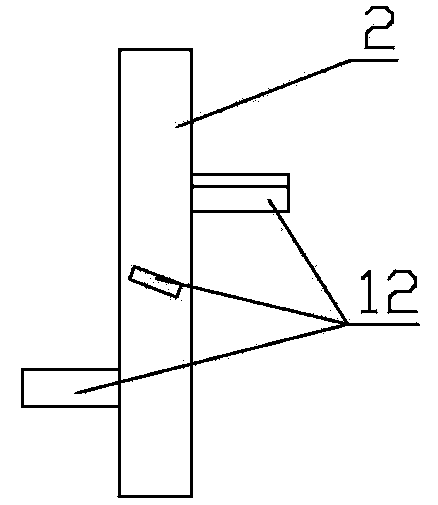

[0015] Such as figure 1 , figure 2 As shown, the inner cavity of the housing 1 is provided with a fixed cylinder 6, the fixed cylinder 6 is coaxially arranged with the stirring shaft 2, the upper end of the fixed cylinder 6 is provided with a connecting spoke 4, and the lower end of the fixed cylinder 6 is provided with There is a circular leaking p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com