Production technology of waterproof wax-impregnated corrugated paper box

A corrugated box and production process technology, applied in the field of water-impregnated wax corrugated box production technology, can solve the problems of unfriendly use of the surrounding environment, human health hazards, difficult quality assurance, etc., and improve the wax hanging effect and stability. Good, improve the effect of production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

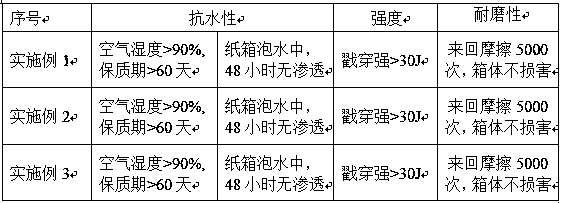

Examples

Embodiment 1

[0024] Preparation of wax liquid: The wax liquid is prepared from the following raw materials in weight ratio: 30% microcrystalline paraffin wax, 10% oxidized polyethylene wax, 5.0% amide wax, 1.5% silica nano powder, 1.0% rosin, surface The active agent is 0.5%, and the balance is water. The oxidized polyethylene wax is an oxidized modification of high-pressure low-density polyethylene wax; the surfactant is sorbitan fatty acid ester; the amide wax is ethylene bisstearic acid amide; and the water is tap water. First add the above-mentioned microcrystalline paraffin, oxidized polyethylene wax, amide wax, surfactant and rosin into the container and heat to 100~110°C, then add water and nano-powder materials, and quickly heat up to 130°C, wait for the microcrystalline paraffin, After the oxidized polyethylene wax and amide wax are fully dissolved, keep the temperature at 85-90°C, stir at a speed of 600-700r / min, stir for 30-40min, and cool to room temperature.

[0025] The prod...

Embodiment 2

[0027] Preparation of wax liquid: wax liquid is prepared from the following raw materials in weight ratio: microcrystalline paraffin wax 50%, oxidized polyethylene wax 5%, amide wax 1.0%, silica nano powder 1.5%, rosin 3.0%, surface Active agent 3%, balance is water. The oxidized polyethylene wax is an oxidized modification of low-pressure high-density polyethylene wax; the surfactant is sorbitan fatty acid ester and polyoxyethylene sorbitan fatty acid ester; the amide wax is ethylene bishard Fatty acid amide; water is deionized water; first add microcrystalline paraffin wax, oxidized polyethylene wax, amide wax, surfactant, rosin to the container and heat to 100~110°C, then add water, nano powder materials, and quickly heat up To 130 ℃, after the microcrystalline paraffin wax, oxidized polyethylene wax and amide wax are fully dissolved, keep the temperature at 85-90 ℃, stir at 600-700r / min, stir for 30-40min, and cool to room temperature.

[0028] The production process of a...

Embodiment 3

[0030] Preparation of wax liquid: the wax liquid is prepared from the following raw materials in weight ratio: microcrystalline paraffin wax 30-50%, oxidized polyethylene wax 5-10%, amide wax 1.0-5.0%, silica nano-powder 0.5~3%, rosin 1.0~5.0%, surfactant 0.5~8%, the balance is water. The oxidized polyethylene wax is an oxidized modified product of high-pressure low-density polyethylene wax; the surfactant is polyoxyethylene sorbitan fatty acid ester; the amide wax is ethylene bisstearic acid amide; water is deionized water. First add microcrystalline paraffin, oxidized polyethylene wax, amide wax, surfactant, and rosin into the container and heat to 100~110°C, then add water and nano powder materials, and quickly heat up to 130°C, wait for the microcrystalline paraffin, oxidized After the polyethylene wax and amide wax are fully dissolved, keep the temperature at 85~90°C, stir at 600-700r / min, stir for 30~40min, and cool to room temperature.

[0031] The production process ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com