Process for continuously preparing emulsified paraffin and device thereof

A technology for emulsifying paraffin and paraffin, applied in the field of emulsifying paraffin, can solve the problems of poor stability, intermittent operation and high energy consumption, and achieve the effects of good stability, enhanced interface strength and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

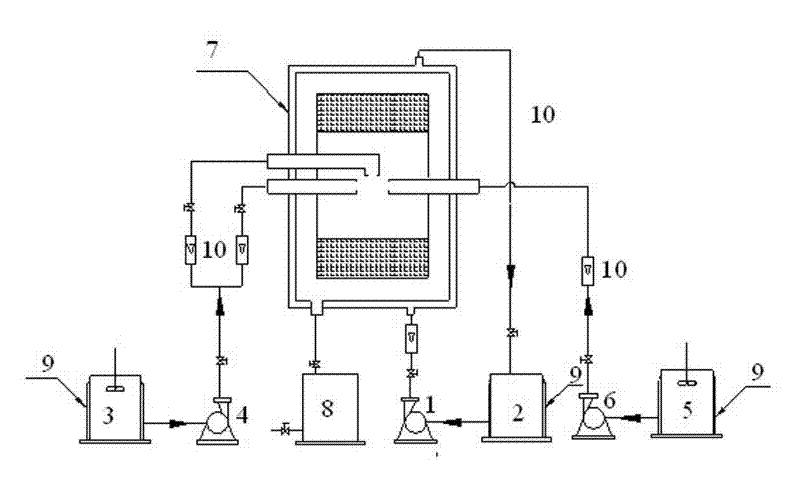

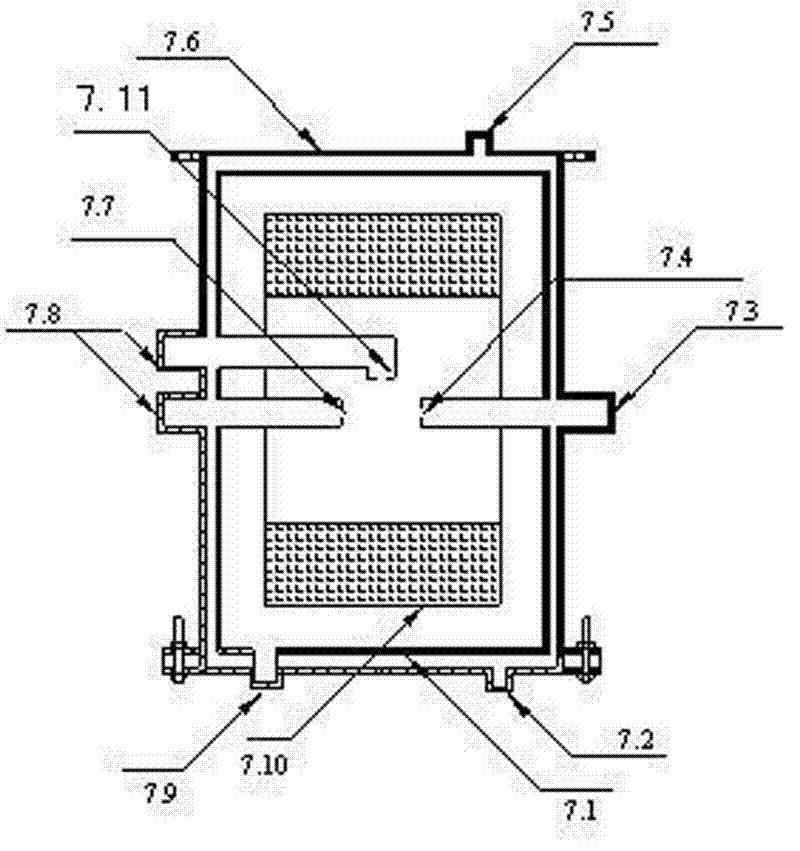

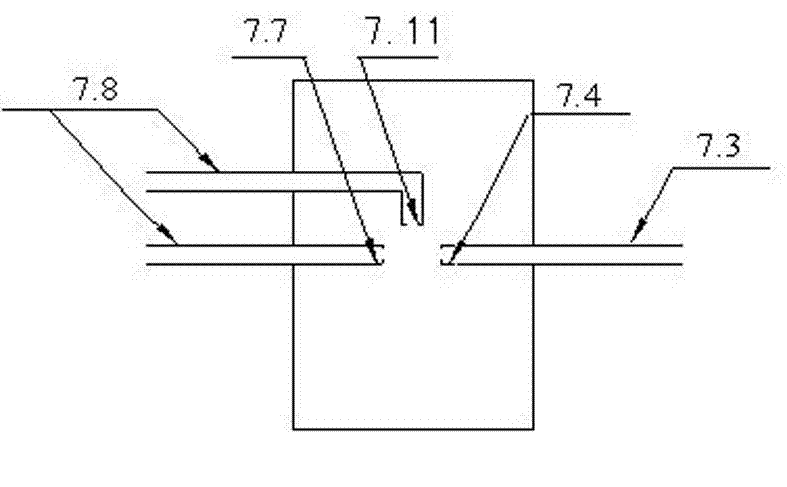

[0038] Heat the temperature of water phase storage tank 3, oil phase storage tank 5, and circulating water storage tank 2 to 80°C to maintain stability, set the temperature of the heating belt to 80°C, and use industrial grade 58 # Fully refined paraffin wax, deionized water as the main raw material, an aqueous solution containing a hydrophilic emulsifier is prepared in the water phase storage tank 3, and a paraffin wax emulsion containing a lipophilic emulsifier is prepared in the paraffin wax storage tank 5. Enter the emulsifier according to the ratio of water phase mass fraction: oil phase mass fraction = 95: 5, the opening diameter of the nozzle is 1mm, which is a circular hole, the filler is plastic mesh, and the initial impact velocity of the water phase and oil phase is 5m / s, the initial velocity of the compensation water phase is 5m / s, the rotational speed of the annular filler is 300rpm, the emulsifier is oleic acid and tween80, the HLB value is 10.5, and the total ma...

Embodiment 2

[0040] Heat the temperature of water phase storage tank 3, oil phase storage tank 5, and circulating water storage tank 2 to 85°C to maintain stability, set the temperature of the heating belt to 85°C, and use industrial grade 54 # Fully refined paraffin wax, deionized water as the main raw material, an aqueous solution containing a hydrophilic emulsifier is prepared in the water phase storage tank 3, and a paraffin wax emulsion containing a lipophilic emulsifier is prepared in the paraffin wax storage tank 5. According to the ratio of water phase mass fraction: oil phase mass fraction = 90:10, it enters the emulsifier. The opening diameter of the nozzle is 1.5mm, which is a square hole. The filler is plastic mesh. The initial impact velocity of the water phase and the oil phase is 8m. / s, the initial velocity of the compensation water phase is 6m / s, the rotational speed of the annular filler is 800rpm, the emulsifier is span80 and OP-10, the HLB value is 12, the fraction of th...

Embodiment 3

[0042] Heat the temperature of water phase storage tank 3, oil phase storage tank 5, and circulating water storage tank 2 to 90°C to maintain stability, set the heat preservation temperature of the heating belt to 90°C, and use industrial grade 68 # Fully refined paraffin wax, deionized water as the main raw material, an aqueous solution containing a hydrophilic emulsifier is prepared in the water phase storage tank 3, and a paraffin wax emulsion containing a lipophilic emulsifier is prepared in the paraffin wax storage tank 5. According to the ratio of water phase mass fraction: oil phase mass fraction = 85:15, it enters the emulsifier. The opening diameter of the nozzle is 2mm, which is a square hole. The filler is stainless steel wire mesh. The initial velocity of the water phase and oil phase is 10m / s, the initial velocity of the compensation water phase is 15m / s, the rotational speed of the annular filler is 1400rpm, the emulsifier is span80 and sodium dodecylbenzenesulfo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com