Ultra-high molecular weight polysiloxane emulsion, preparation method and special equipment thereof

A polysiloxane emulsion, ultra-high molecular weight technology, applied in chemical instruments and methods, applications, mixers, etc., can solve the problems of insufficient smoothness and oily feeling, short holding time of hand feeling, low monomer conversion rate, etc. To achieve the effect of good emulsification effect, high molecular weight and high dispersion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

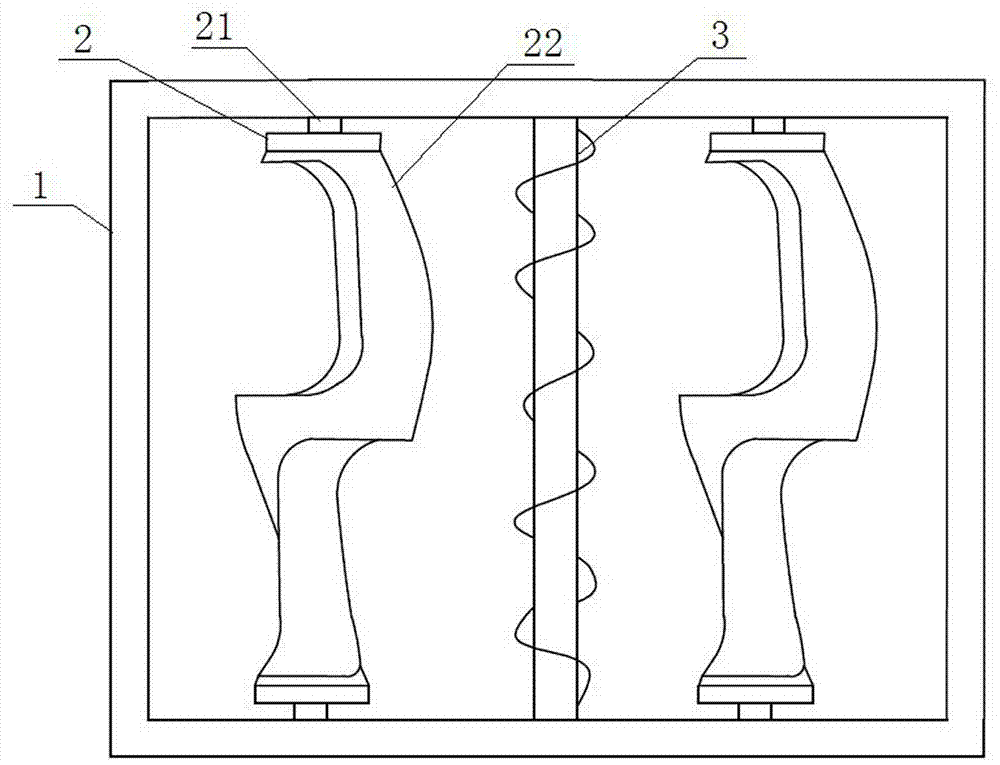

Image

Examples

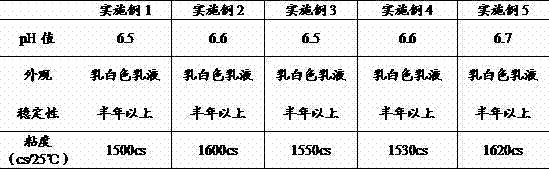

Embodiment 1

[0025] A kind of ultrahigh molecular weight polysiloxane emulsion, the preparation method of this ultrahigh molecular weight polysiloxane emulsion is as follows: (1) 20g of fatty alcohol polyethylene oxide, 4g of fatty alcohol polyoxyethylene ether, lauryl Put 6g of sodium sulfonate and 4g of glycerin in turn into a stirred reactor and stir for 1h, and stir while adding to prepare a composite emulsifier for use. The HLB value of the composite emulsifier is 12.3; Put 100g of oxane, 33g of composite emulsifier and 200g of deionized water into the disperser in sequence, evacuate to -0.01Mpa, heat to 40°C, stir for 2h, and discharge to obtain ultra-high molecular weight polysiloxane emulsion.

Embodiment 2

[0027] A kind of ultrahigh molecular weight polysiloxane emulsion, the preparation method of this ultrahigh molecular weight polysiloxane emulsion is as follows: (1) 20g of fatty alcohol polyethylene oxide, 5g of fatty alcohol polyoxyethylene ether, lauryl Put 6g of sodium sulfonate and 3g of glycerin in turn into a stirred reactor and stir for 1h, and stir while adding to prepare a composite emulsifier for use. The HLB value of the composite emulsifier is 12.4; Put 100g of oxane, 33g of composite emulsifier and 220g of deionized water into the disperser in sequence, vacuumize to -0.01Mpa, heat to 45°C, stir for 3h, and discharge to obtain ultra-high molecular weight polysiloxane emulsion.

Embodiment 3

[0029] A kind of ultrahigh molecular weight polysiloxane emulsion, the preparation method of this ultrahigh molecular weight polysiloxane emulsion is as follows: (1) 20g of fatty alcohol polyethylene oxide, 5g of fatty alcohol polyoxyethylene ether, lauryl Put 4g of sodium sulfonate and 4g of glycerin in turn into a stirred reactor and stir for 1.5h, and stir while adding to prepare a composite emulsifier for use. The HLB value of the composite emulsifier is 12.3; 100g of siloxane, 32g of composite emulsifier and 250g of deionized water were placed in the disperser in sequence, vacuumed to -0.01Mpa, heated to 42°C, stirred for 2.5h, and discharged to obtain an ultra-high molecular weight polysiloxane emulsion.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com