Emulsifying unit for coating production and operation method thereof

An emulsification device and paint technology, applied in chemical instruments and methods, mixing methods, mixers with rotary stirring devices, etc., can solve the problems of small application range, inconvenient operation, poor paint emulsification quality, etc., to enhance product quality. , reduce labor intensity, improve emulsification efficiency and emulsification quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

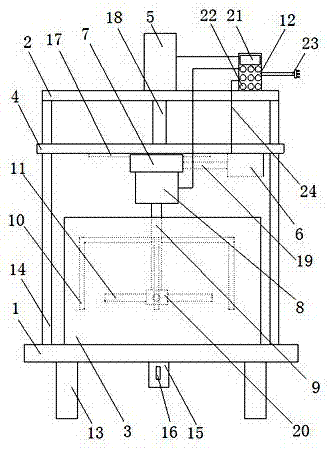

[0021] as attached figure 1 As shown, an emulsification device for paint production, including bottom plate 1, top plate 2, emulsification tank 3, adjustment plate 4, cylinder one 5, cylinder two 6, adjustment block 7, motor 8, transmission shaft 9, stirring rod one 10. Stirring rod 2 11 and controller 12, characterized in that: the bottom plate 1 is provided with feet 13 and uprights 14, the top plate 2 is set on the uprights 14, and the emulsification tank 3 is set on the bottom plate 1, and a discharge pipe 15 is set on the emulsification tank 3, the adjustment plate 4 is set on the column 14, and a guide rail 17 is set on the adjustment plate 4, and the cylinder one 5 is set on the top plate 2 , and cylinder one 4 is provided with piston rod one 18, described cylinder two 6 is arranged on the adjustment plate 4, and cylinder two 6 is provided with piston rod two 19, and described adjustment block 7 is arranged on guide rail 17 on, and the adjustment block 7 is connected w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com