Removable device for reheating and emulsifying a liquid and machine provided with such a device

A liquid, main body technology, applied in the field of hot milk foam, can solve the problems of tube rupture, deformation, etc., and achieve the effect of simple implementation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

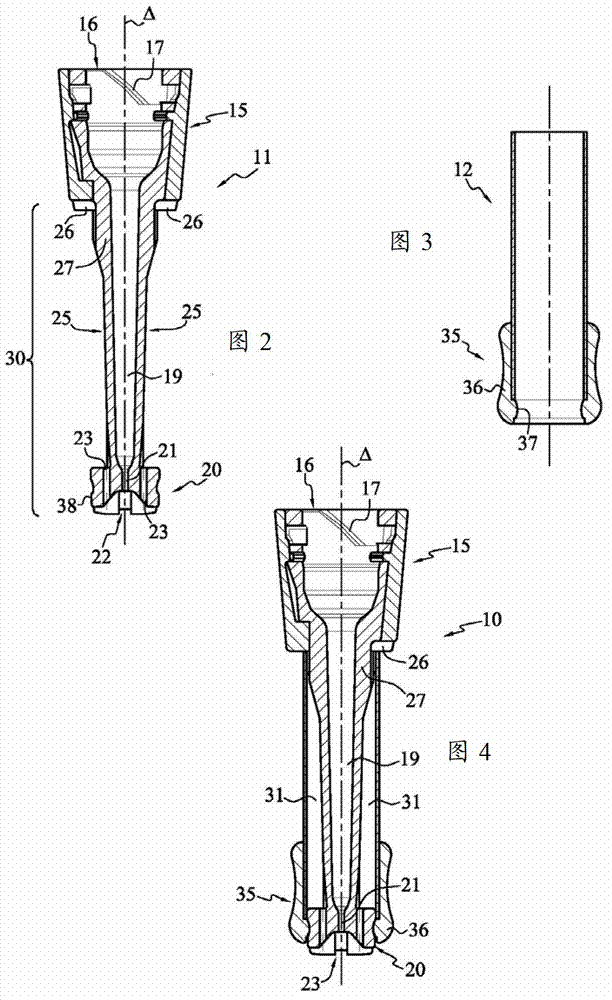

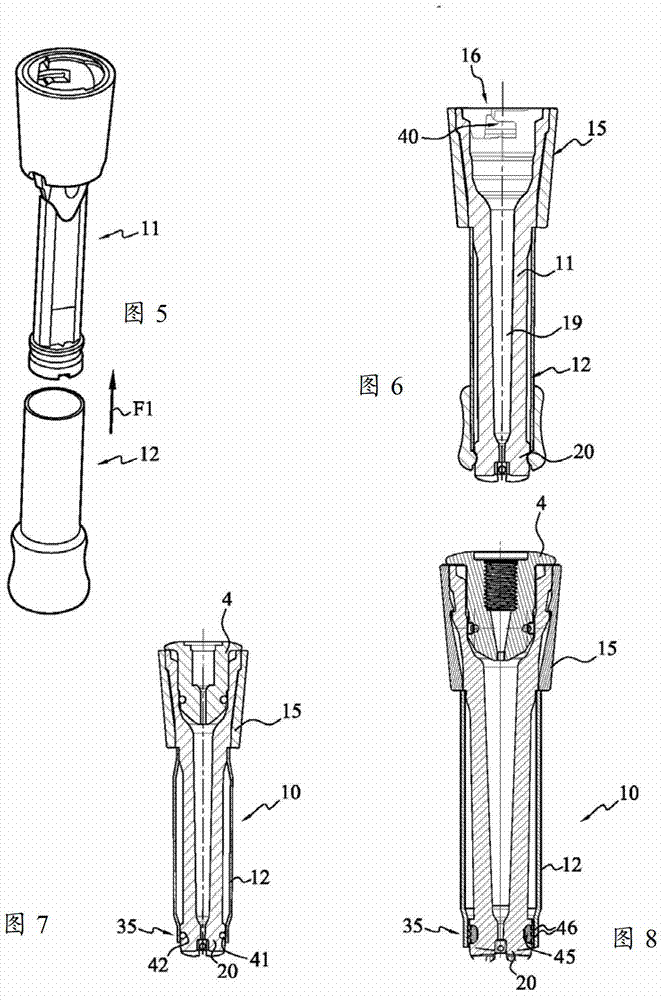

[0032] It should be noted that structural and / or functional elements common to different variants in these figures may have the same reference numerals.

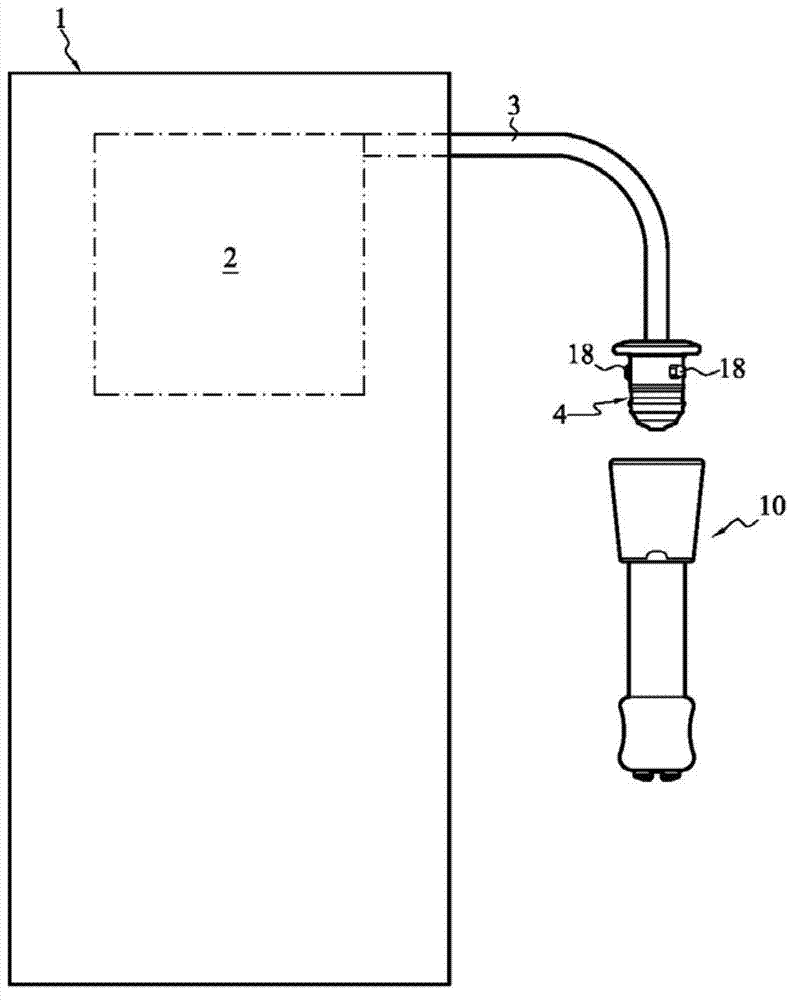

[0033] Machines for preparing hot beverages according to the invention are, for example but not exclusively, "espresso-type" coffee machines, such as figure 1 Shown includes a frame 1 containing a steam source 2, such as an electric boiler, which is connected to figure 1 A high pressure pump not shown is connected to the water container. The steam source 2 is connected to a drainage tube 3 which extends outside the frame 1 and whose end is equipped with a connection element 4 of a device 10 for heating and emulsifying the liquid. According to an example, the device 10 is mounted on the connection element 4 in a detachable manner.

[0034] Once mounted on this connecting element 4, the device 10 serves to ensure the injection of steam mixed with air into the liquid to be heated and emulsified. Thus, within the context of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com