Stearic acid soap paper coating lubricant

A technology of stearic acid soap and lubricant, which is applied in lubricating compositions, papermaking, textiles and papermaking, etc., can solve the problems of low stearic acid soap content, high production cost, poor stability, etc., and achieve stearate content High, low production cost, good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

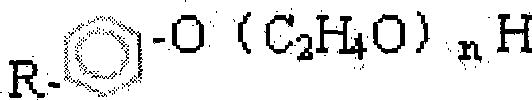

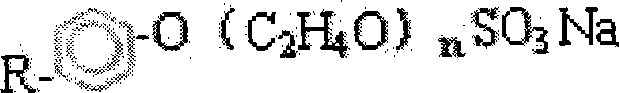

[0024] In a 1000-liter shearing reactor, add water 500kg, calcium stearate 450kg, polyoxyethylene nonyl aryl ether (n=15) 10.5kg, polyoxyethylene nonyl aryl ether (n=4) Sodium sulfonate 10.5kg, calcium hydroxide 3.5kg, diethylene glycol 15kg and oleic acid 22kg, open agitator in the high-shear reactor, and the agitator rotating speed is 1200rpm, until the material in the above-mentioned high-shear kettle is stirred evenly, then The homogeneously mixed material is passed through a flow energy mill to make it homogenized, and the obtained product is a white dispersion liquid.

[0025] Polyoxyethylene nonylaryl ether (n=15) and polyoxyethylene nonylaryl ether (n=4) were purchased from Dow Chemical NP-15 and NP-4 products, in which polyoxyethylene nonylaryl ether was used Ether (n=4) prepares polyoxyethylene nonyl aryl ether (n=4) sodium sulfonate, and method is conventional sulfonation reaction, and preparation process is as follows: in reactor, add NP-4 (polyoxyethylene nonyl A...

Embodiment 2

[0029] In a 1000-liter shearing reactor, add water 450kg, calcium stearate 500kg, polyoxyethylene octyl aryl ether (n=15) 12kg, polyoxyethylene octyl aryl ether (n=3.5) sodium sulfonate 12kg, Calcium hydroxide 3.8kg, diethylene glycol 22kg, oleic acid 25kg, open the agitator in the high-shear reactor, the agitator rotating speed is 1200rpm, until the material is stirred evenly, it is homogenized through the flow energy mill, and the product obtained is White dispersion.

[0030] The product obtained in Example 2: a solid content of 55%, a viscosity of 110 mPa·s, a pH value of 11, and a particle size of 5 μm.

Embodiment 3

[0032] In a 1000-liter shearing kettle, add water 440kg, calcium stearate 550kg, polyoxyethylene nonyl aryl ether (n=15) 14kg, polyoxyethylene nonyl aryl ether (n=3.5) sulfonic acid Sodium 14kg, calcium hydroxide 3.8kg, glycerin 22kg, oleic acid 25kg, open the agitator in the high-shear reactor, the agitator rotating speed is 1200rpm, until the material is stirred evenly, it is homogenized through the flow energy mill, and the obtained product It is a white dispersion.

[0033] The product obtained in Example 3: a solid content of 57%, a viscosity of 150 mPa·s, a pH value of 11, and a particle size of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com