Preparation of rubber nano fibre

A technology of rubber nanofibers and rubber, which is applied in fiber processing, spinning solution preparation, fiber chemical characteristics, etc. It can solve the problems of high elastic rubber that is difficult to be continuous and stabilized, the fiber diameter is thick, and the shape stability is poor, so as to achieve continuous Good performance and stability, stable shape, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

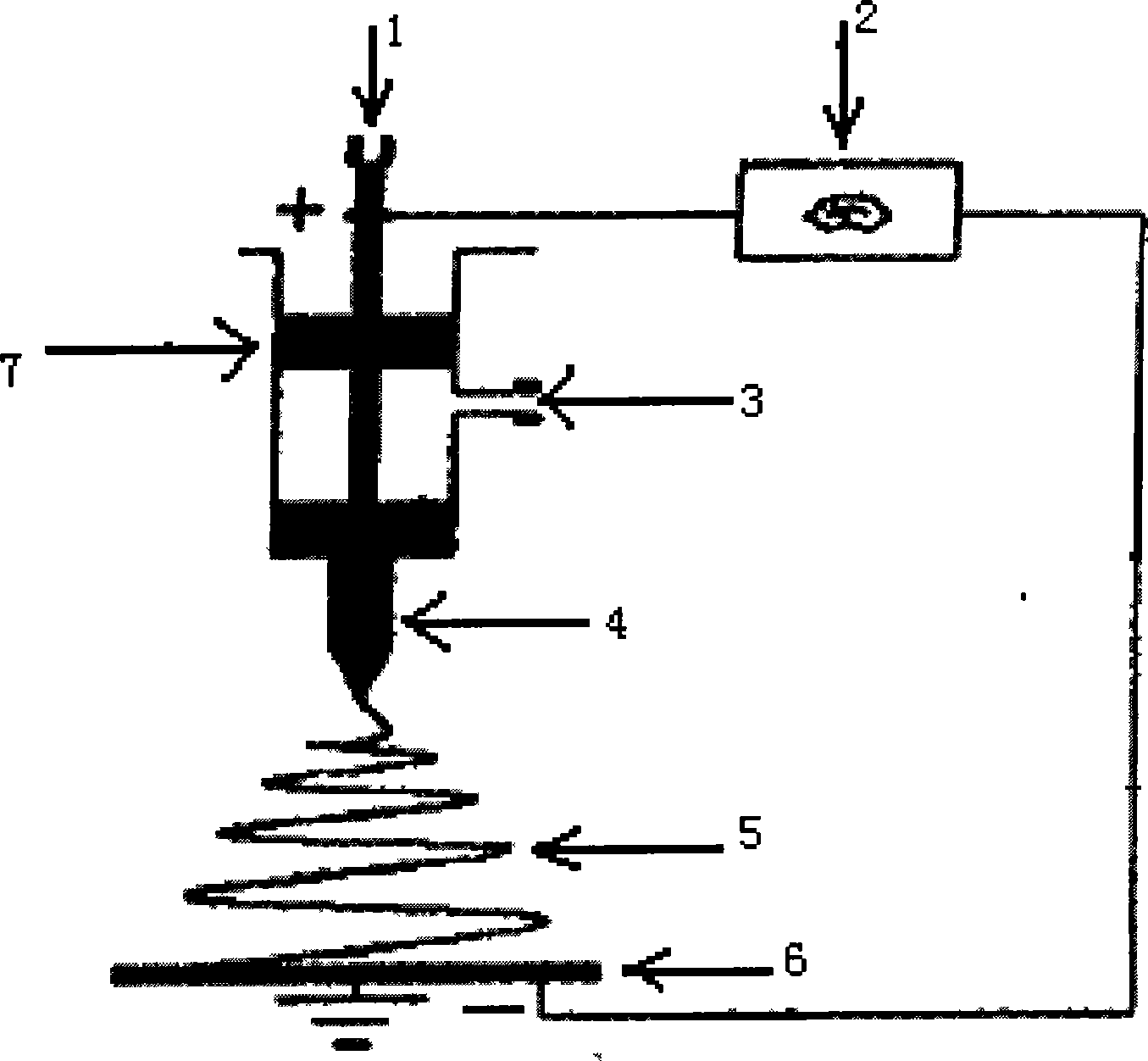

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Mix 1g (100 parts) of silicone rubber, 0.25g NaCl (25 parts) and 0.3g (30 parts) silane coupling agent-modified fumed silica in 10g of dichloromethane, stir evenly to prepare rubber solution to obtain a core layer solution, before electrospinning, add 0.005g (0.5 part) of a crosslinking agent to the core layer solution (in the crosslinking agent, organopolysiloxane A is a molecular chain with trimethylsilane at both ends Oxygen-terminated methylhydrogenpolysiloxane, platinum metal content in alcohol solution B of chloroplatinic acid is 10000ppm, and the mass ratio of A and B components is 1:1); 1.5g polyvinylpyrrolidone is dissolved in 10g ethanol , stir evenly to obtain the shell layer solution; coaxial electrospinning, set the distance between the spinneret and the receiving plate to be 15cm, the flow rate of the core layer solution is 1.0ml / h, the diameter of the spinneret is 0.5mm, the shell layer solution The flow rate was 2.0ml / h, the diameter of the sp...

Embodiment 2

[0021] Example 2: 1g (100 parts) butyl rubber, 0.05g AgNO 3(5 parts) and 0.05g (5 parts) of fumed silica modified with a silane coupling agent were mixed in 10 g of tetrahydrofuran, and stirred evenly to prepare a rubber solution to obtain a core layer solution. Before electrospinning, in the core layer solution Add 0.1g (10 parts) of cross-linking agent (organopolysiloxane A in the cross-linking agent is methyl hydridopolysiloxane whose molecular chain ends are capped by trimethylsiloxy, alcohol of chloroplatinic acid) The platinum metal content in solution B is 100 ppm, and the mass ratio of the two components A and B is 1:2); 1.2 g of polyethylene oxide is dissolved in 10 g of ethanol, and the shell solution is prepared by stirring uniformly; coaxial electrospinning, set The distance between the spinneret and the receiving plate is 20cm, the flow rate of the core layer solution is 0.8ml / h, the diameter of the spinneret is 0.6mm, the flow rate of the shell layer solution is ...

Embodiment 3

[0022] Example 3: 1g (100 parts) cis-butadiene rubber, 0.2g AgNO 3 (20 parts) and 0.1 g (10 parts) of silane coupling agent-modified precipitated silica were mixed in 8 g of tetrahydrofuran, stirred evenly to prepare a rubber solution to obtain a core layer solution, before electrospinning, in the core layer solution Add 0.03g (3 parts) of cross-linking agent (organopolysiloxane A in the cross-linking agent is dimethylsiloxane-methylhydrosiloxane whose molecular chain ends are capped by trimethylsilyloxy groups) Copolymer, the platinum metal content in the alcohol solution B of chloroplatinic acid is 3000ppm, and the mass ratio of the two components A and B is 1:3); 1.0g of polyvinyl alcohol is dissolved in 10g of ethanol, and the shell layer solution is obtained by stirring evenly ; Coaxial electrospinning, set the distance between the spinneret and the receiving plate to be 15cm, the flow rate of the core layer solution is 1.5ml / h, the diameter of the spinneret is 1.0mm, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com