Water-soluble polymer/graphene composite fiber as well as preparation method and application thereof

A water-soluble polymer and graphene composite technology, applied in the direction of spinning solution preparation, single-component synthetic polymer rayon, chemical post-treatment of synthetic polymer rayon, etc., can solve the problem of high brittleness of pure graphene fibers, Difficult to mix and disperse, high cost of raw materials, etc., to achieve the effects of easy continuous scale, wide application prospects, and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

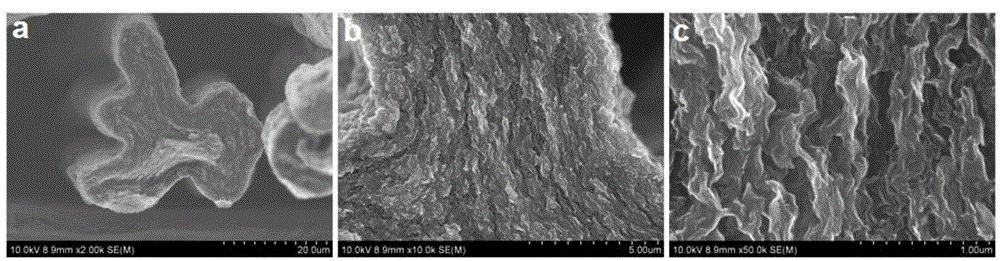

[0053] The process of preparing polyvinyl alcohol / graphene composite fibers with a spinning solution with a mass ratio of PVA / GO of 5 / 95 is as follows:

[0054] (1) 1.9 g of graphene oxide was added to 96 g of NaOH aqueous solution with a pH value of 10, and ultrasonically treated for 30 min to obtain a graphene oxide solution. Then add 2g of 5wt% (mass fraction) PVA aqueous solution, and add 5M NaOH solution to adjust the pH value to 11, and continue ultrasonic treatment for 30min to obtain a PVA / GO mass ratio of 5 / 95, a pH value of 11, and a solid content of 2%. Composite spinning solution of composite spinning solution.

[0055] (2) Extrude the composite spinning solution obtained in (1) through the spinneret hole at a speed of 1.5m / min into static methanol for solidification, lead the wet fiber out of the coagulation bath, dry it with hot air, and wind it on the silk tube , to obtain PVA / GO composite fibers; wherein, the winding line speed of the filament package is 1.5m / ...

Embodiment 2

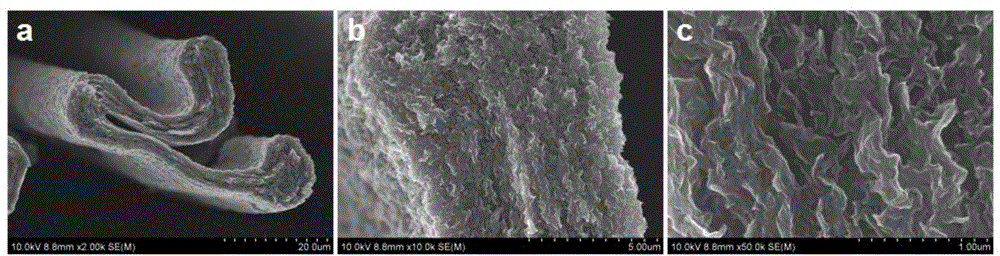

[0059] The process of preparing polyvinyl alcohol / graphene composite fibers with a spinning solution with a mass ratio of PVA / GO of 10 / 90 is as follows:

[0060] (1) Add 1.8g graphene oxide and 4g 5wt% PVA aqueous solution to 94.2g water, use concentrated ammonia water to adjust the pH value to 9, then use a high-speed emulsifier to disperse and mix for 1 hour, and finally continue to add ammonia water to adjust the pH value to 11, A composite spinning solution is obtained.

[0061] (2) The composite spinning solution obtained in (1) is extruded at a speed of 1.5 m / min through a spinneret hole into a parallel-flowing 80% acetic acid aqueous solution and solidified into fibers. Wherein, the flow velocity of acetic acid is 1.5 m / min, that is, the drawing ratio of the nozzle is 1.0 times. Then the wet fiber was taken out of the coagulation bath, dried by hot air, and then wound continuously on the silk tube to obtain the PVA / GO composite fiber.

[0062] (3) The fibers obtained ...

Embodiment 3

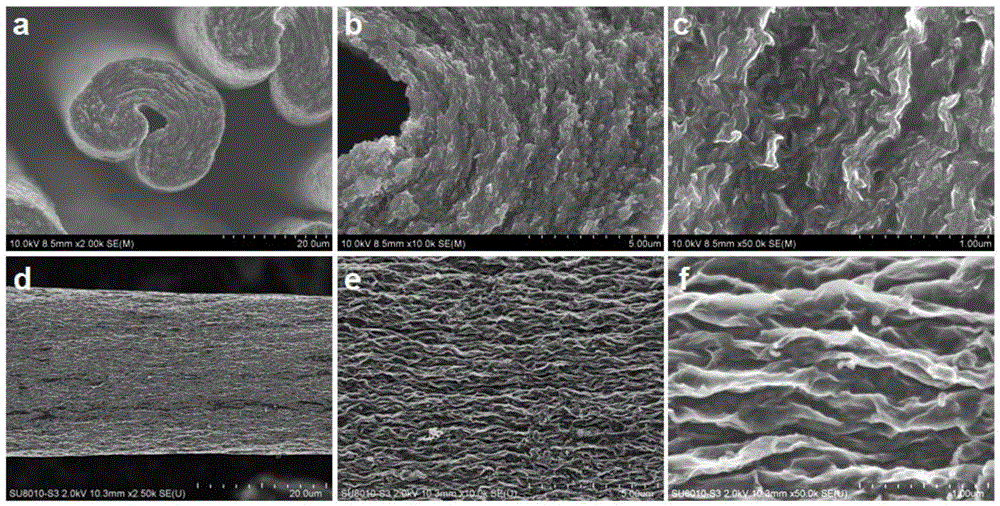

[0065] The process of preparing polyvinyl alcohol / graphene composite fibers with a nozzle draw ratio of 1.0 times with a spinning solution with a PVA / GO mass ratio of 20 / 80 is as follows:

[0066] (1) Add 1.6g graphene oxide and 8g 5wt% PVA aqueous solution to 90.4g water, use concentrated ammonia water to adjust the pH value to 9, then use a high-speed emulsifier to disperse and mix for 1 hour, and finally continue to add ammonia water to adjust the pH value to 10, A composite spinning solution is obtained.

[0067] (2) The composite spinning solution obtained in (1) is extruded into rotating acetic acid with a speed of 1.5m / min through the spinneret hole and solidified into fibers, wherein the distance between the spinneret and the center of rotation is 3cm, and the speed of rotation is 8rpm , that is, the nozzle stretch ratio is 1.0 times. The wet fiber was taken out of the coagulation bath, dried by an infrared lamp, and then wound continuously on a silk tube to obtain a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com