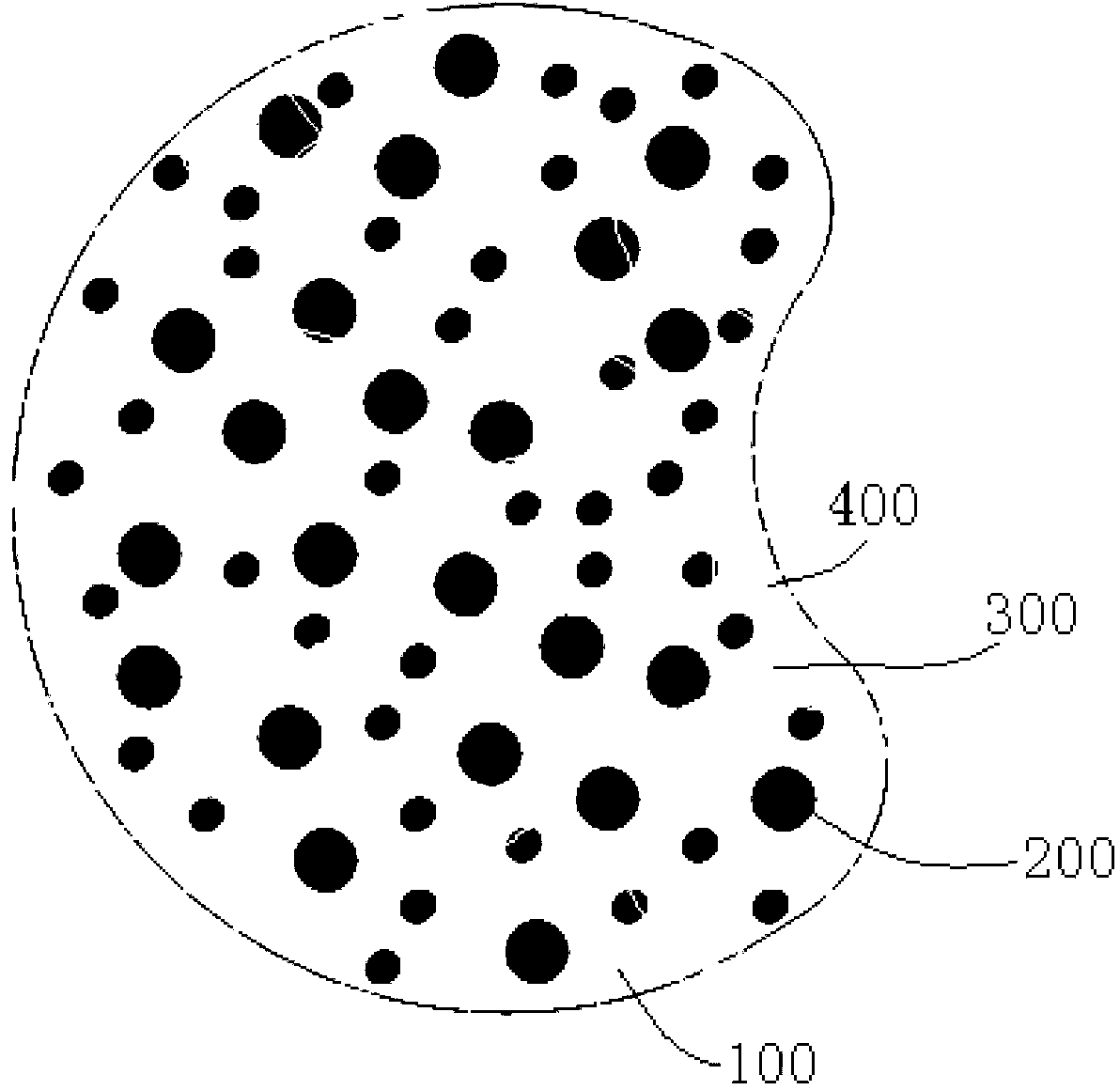

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

A technology of silicon-carbon composite materials and nano-silicon, which is applied in the manufacture of rayon, the chemical post-treatment of synthetic polymer rayon filaments, and the chemical characteristics of fibers, etc., can solve the problem that silicon expansion cannot be completely solved, and the carbon matrix does not really stabilize Structure and other issues, to achieve the effect of improving electrochemical performance, improving lithium storage capacity, and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Compared with Comparative Example 1.

[0054] Step 1: Preparation of spinning solution. The preparation method and conditions of the spinning solution were the same as the first step in Comparative Example 1, and a mixed solution in which Si was uniformly dispersed in the DMF solution of PAN was obtained.

[0055] The second step: electrospinning to prepare Si-doped PAN nanofibers. Put the mixed solution prepared in the first step into a syringe, extrude the spinning solution at a flow rate of 0.3mL / h, and perform electrospinning under a high-voltage electric field of 18kV. After passing through the air for a certain distance, the spinning solution enters the solidification Cured in a bath to form. The air section distance between the spinneret and the coagulation bath was 3 cm, the coagulation bath was a water bath at room temperature, and the coagulation time was 2 h. The as-spun fibers were vacuum-dried at 60 °C for 12 h to obtain porous PAN-Si composite nanofibers...

Embodiment 2

[0061] Compared with Comparative Example 1.

[0062] Step 1: Preparation of spinning solution. The preparation method and conditions of the spinning solution were the same as the first step in Example 1, and a mixed solution in which Si was uniformly dispersed in the DMF solution of PAN was obtained.

[0063] The second step: electrospinning to prepare PAN nanofibers doped with Si and PVC. Put the mixed solution prepared in the first step into a syringe, extrude the spinning solution at a flow rate of 0.3mL / h, and perform electrospinning under a high-voltage electric field of 18kV. After passing through the air for a certain distance, the spinning solution enters the solidification Cured in a bath to form. The air section distance between the spinneret and the coagulation bath was 3 cm, the coagulation bath was absolute ethanol at room temperature, the coagulation time was 2 h, and the as-spun fibers were vacuum-dried at 60 °C for 12 h to obtain porous PAN-Si composite nanof...

Embodiment 3

[0069] Compared with Comparative Example 2.

[0070]Step 1: Preparation of spinning solution. The preparation method and conditions of the spinning solution are the same as the first step in Comparative Example 2.

[0071] The second step: electrospinning to prepare Si-doped PAN nanofibers. The spinning conditions were the same as the second step in Example 1.

[0072] The third step: oxidation treatment of primary nanofibers. The oxidation treatment conditions were the same as the third step in Comparative Example 2.

[0073] The fourth step: carbonization of nanofibrous oxide and formation of nano-silicon-carbon composite material. The carbonization conditions were the same as in the fourth step of Comparative Example 2.

[0074] Step 5: Preparation and electrochemical performance testing of silicon-carbon nanocomposite anode materials. The material preparation and testing methods are the same as the fifth step in Comparative Example 2.

[0075] According to the above...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com