Patents

Literature

49results about How to "Dimensionally stable structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Silicon-carbon composite material with nano micropores and preparation method as well as application thereof

ActiveCN103305965AImprove lithium storage performanceImprove electrochemical performanceCell electrodesFilament/thread formingCarbon compositesCarbon fibers

The invention discloses a silicon-carbon composite material with nano micropores and a preparation method as well as application thereof. The material comprises nano-silicon (Si) particles and a carbon nanofiber matrix, wherein the nano-silicon particles are dispersed in the carbon nanofiber matrix; and nano pores and micropores communicated with the nano pores are distributed in the carbon nanofiber matrix. The method comprises the steps of dissolving the nano-Si particles and polyacrylonitrile (PAN) in a solvent to prepare a mixed spinning solution, then carrying out electrostatic spinning on the mixed spinning solution, and curing spinning trickles in a coagulating bath to obtain a porous PAN-Si composite nanofiber; and then carrying out oxidation and carbonization treatment in sequence to obtain the silicon-carbon composite material with a nano micropore structure. The silicon-carbon composite material is applied to preparation of lithium ion battery cathode materials. Compared with the prior art, the silicon-carbon composite material ensures the overall electron transport capacity of the material while reserving buffer space for expansion of the nano-Si particles.

Owner:深圳石墨烯创新中心有限公司

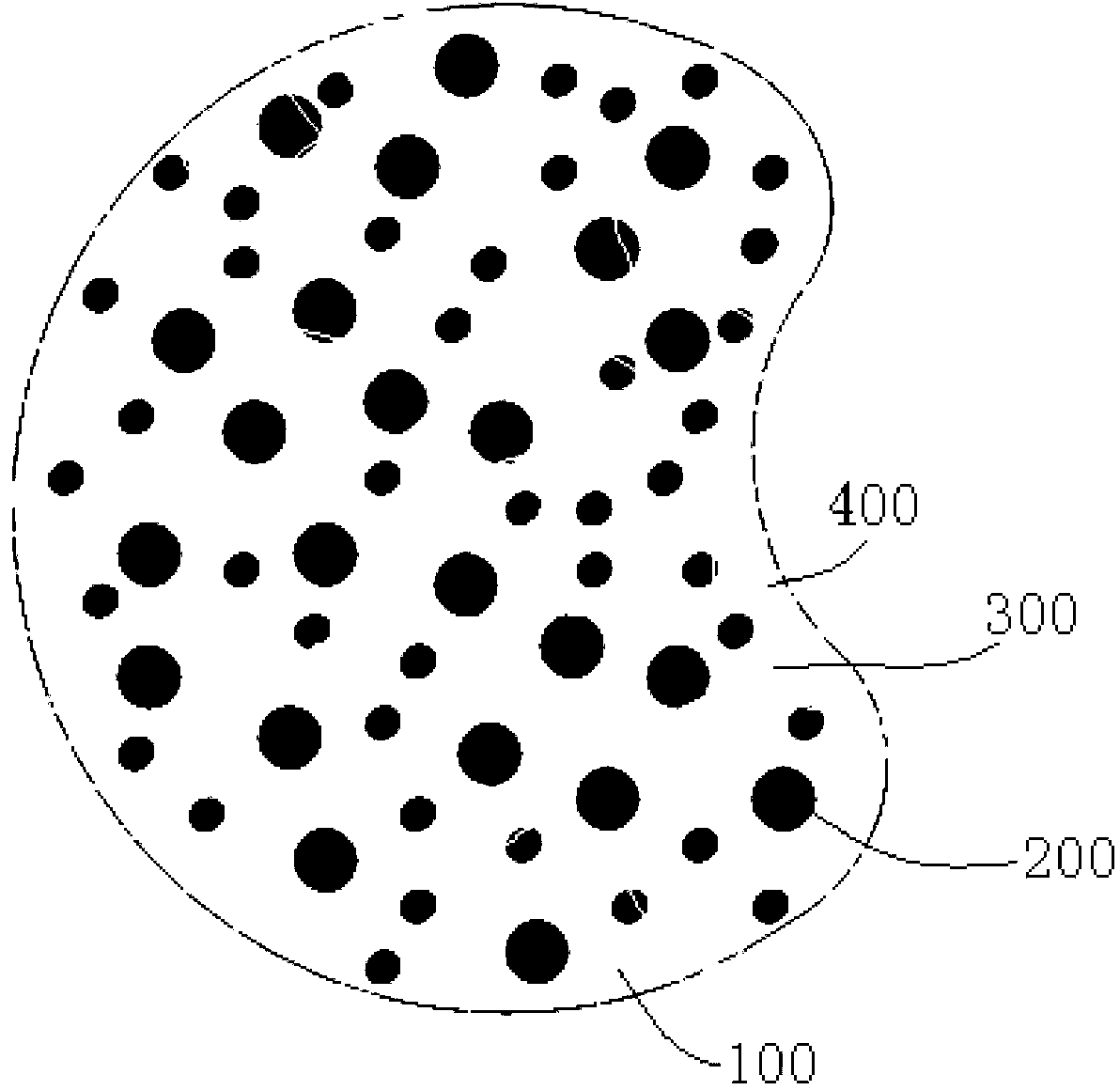

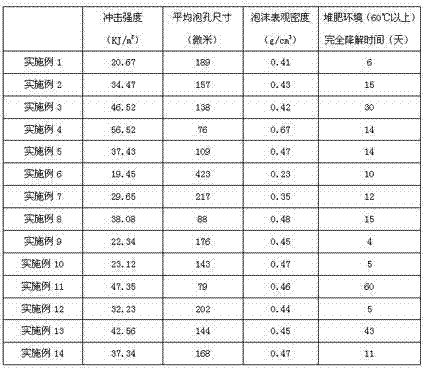

Blended foam material based on polycaprolactone (PCL) and modified polylactic acid (PLA) and preparation method thereof

The invention discloses a blended foam material based on PLC and modified PLA and a preparation method thereof, and belongs to the foam material field. The foam material comprises, by weight, 60-90 parts of PLA, 1-25 parts of PCL, 2-10 parts of reinforcing agents, 1-3 parts of nanometer nucleating agents, 4 parts of foaming agents, 0.1-1 part of a blowing promoter, 1-3 parts of environment-friendly flame retardants and 0.5-1 part of a surfactant. According to the foam material and the preparation method thereof, composite foamed plastics with good mechanical properties and superior surface quality can be prepared.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Solid oxide fuel battery anode and its production

InactiveCN1897337AOvercome carbon depositsOvercome stabilityCell electrodesCerium(IV) oxideMaterial physics

A solid oxide fuel battery anode and the preparation method, the characteristic is: adulterates the titanic mine cadmium acid lanthanum or the titanate compound oxide as the anode structure framework and the main electron conducting phase, uses the ion infusing method, the macromolecule modeling board method, the sol-gel method, or the suspending grain pulp spreading method, prepares the nanometer grain anode active substance multi-hole film with the thickness of 0.05-5 micron in the inner and outer hole surface of the multi-hole anode structure framework; the anode active substance includes the ceric oxide, or the adulterating ceric oxide, or the zirconia based oxygen ionic conductor electrolyte, or the cerate based proton conductor electrolyte, or the mixture of the above active substance, or the above active substance adding a small quantity of Ni or Ni-Cu and V2O5. The invention is structure stabilization, high conducting rate, high catalyzing activity of the fuel oxidation, matching with the closing material at physics and chemistry, structure size stabilization, anti-carbon deposition, is fit for the fuel operation of the hydrocarbon directly.

Owner:UNIV OF SCI & TECH OF CHINA

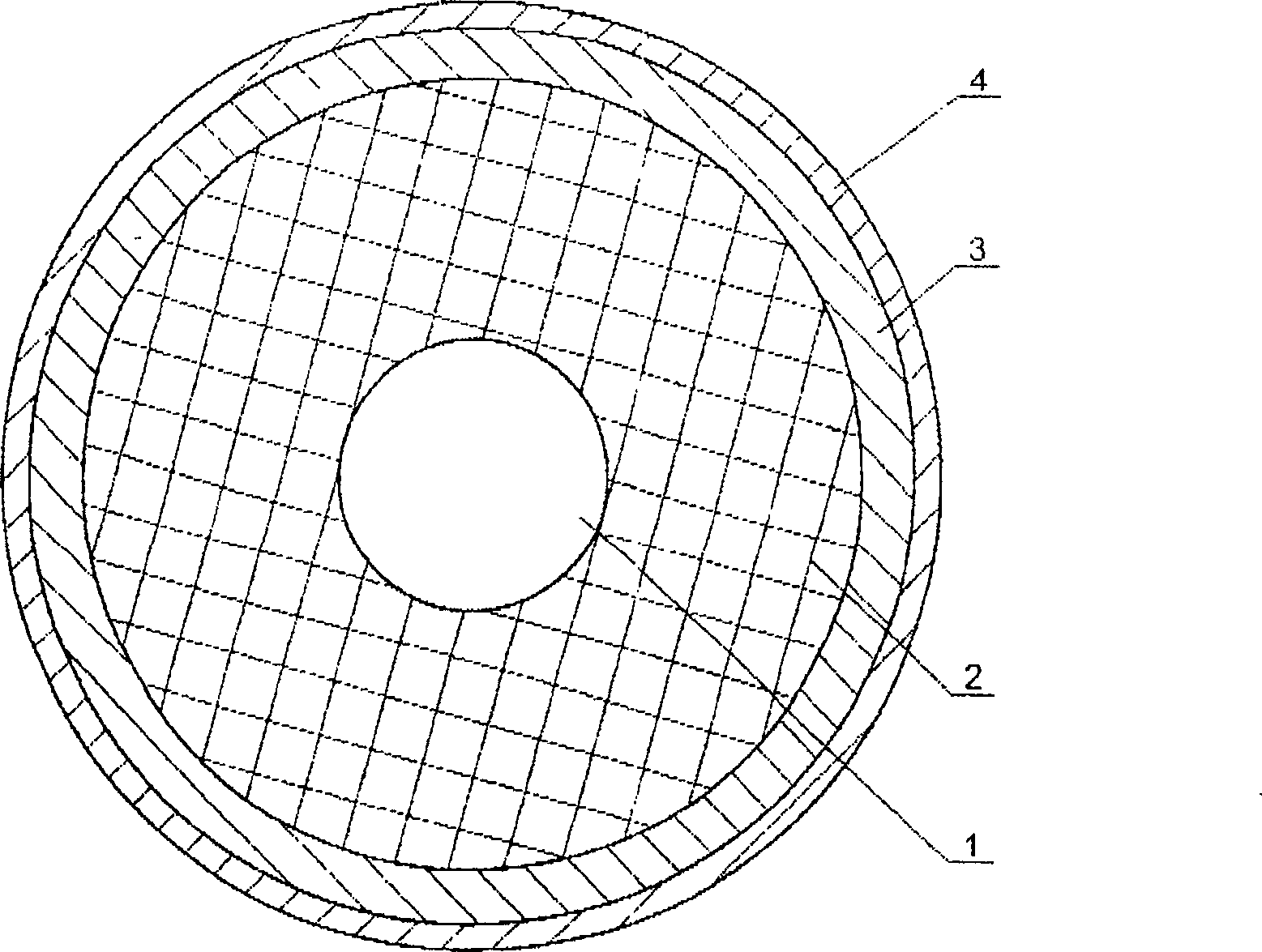

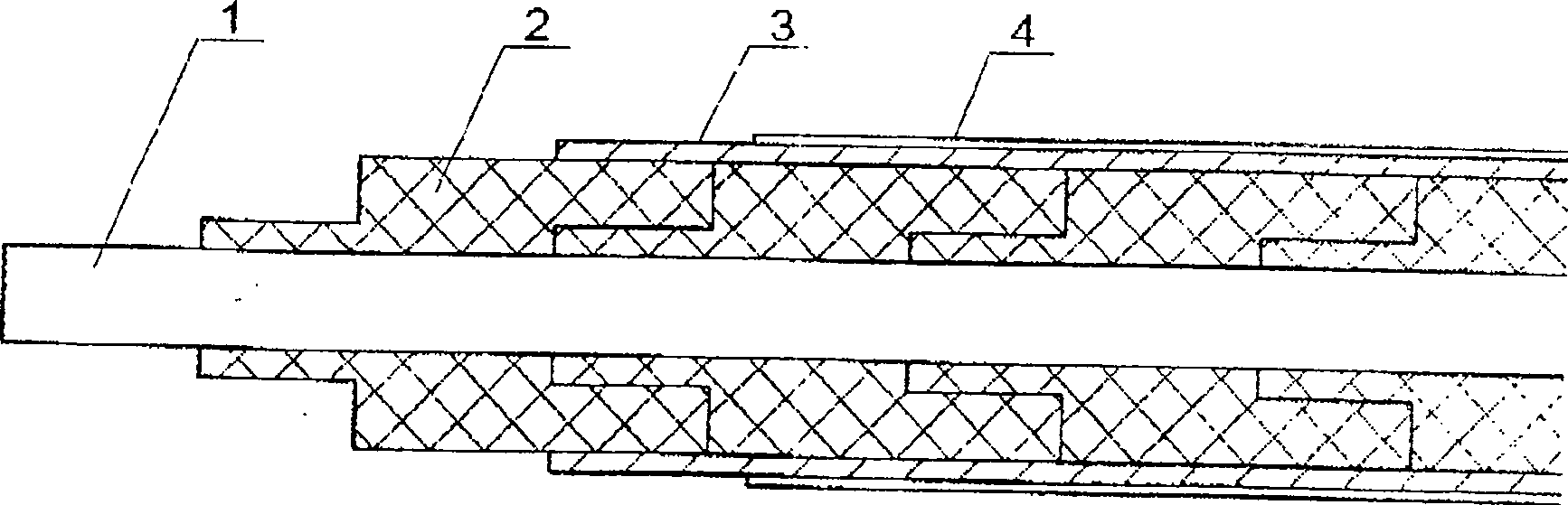

Composite component of meridian tyre cord fabric layer and air barrier and preparation technology

ActiveCN101612867ASimple production processIncrease productivitySpecial tyresPneumatic tyre reinforcementsRadial tireEngineering

The invention discloses a composite component of meridian tyre cord fabric layer and air barrier and a preparation technology. Base material rubber, an aging-proof system, a reinforcing system, a vulcanization system and a radiosensitizer are mixed at a ratio to form a mixture; the rubber mixture is mixed to smelt in an internal mixer to be prepared into a tyre body cord fabric layer component and a lining air barrier component respectively according to the production technology of the tyre body cord fabric layer and the lining air barrier component; then the tyre body cord fabric layer component and the lining air barrier component are compounded into an integral composite component on a compound machine; an electron accelcrator is used for radiating the composite component; under the condition of limited-oxygen radiation, radiation prevulcanization is carried on the composite component of the tyre cord fabric layer and the lining air barrier. The composite component of the tyre cord fabric layer and the air barrier, which is radiated by the invention, has high Green strength, stable structure size and performance, saves raw material, has small radiation dose and high production efficiency and is favourable for environment protection.

Owner:BEIJING RADIATION APPL RES CENT

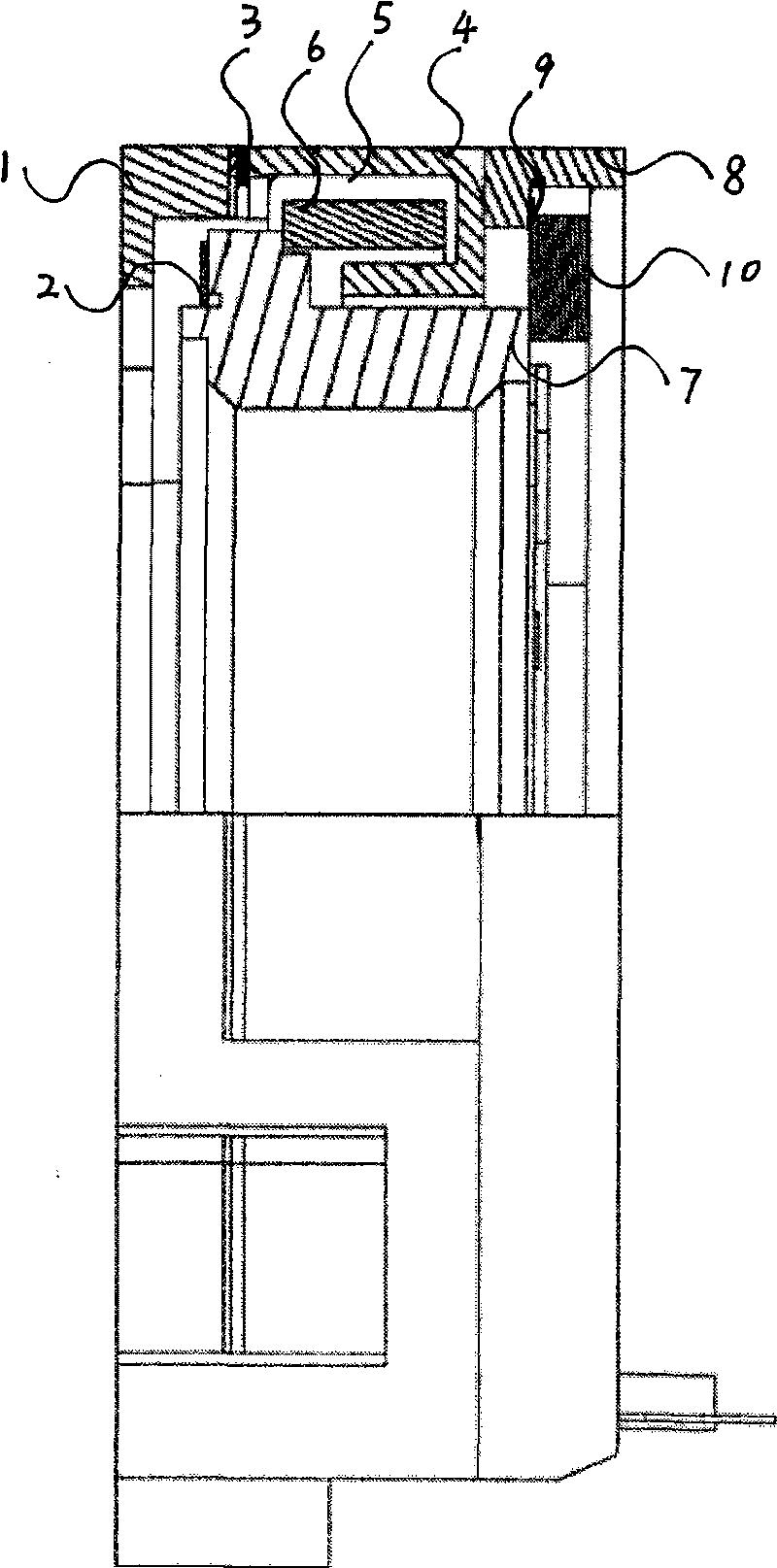

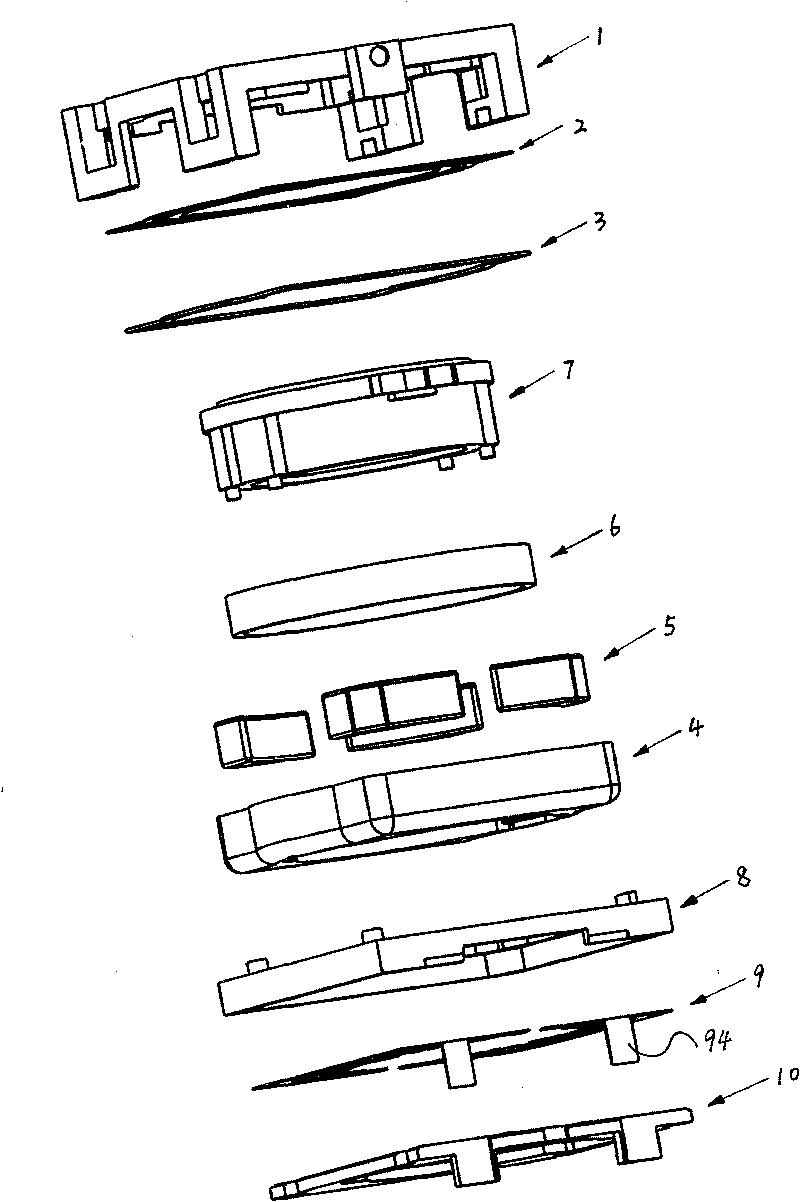

Lens driving device

InactiveCN101738704AIncreased electromagnetic inductionImprove quality and efficiencyMountingsPropulsion systemsNon symmetricEngineering plastic

The invention relates to a lens driving device, comprising a magnet yoke ring with a lodestone; the magnet yoke ring is arranged between a front frame and a back frame and is provided with a cylindrical lens supporter with coil; the front part of the lens supporter is provided with a front backup plate and a front spring, the back part thereof is provided with a back spring; in addition, the magnet yoke ring is also provided with arc rectangular outer frames at two sides, the outer frames are provided with a circular vertical convex edge with two symmetrically arranged openings, a rectangular inner chamber with arcs arranged at two sides is formed between the outer frames and the vertical convex edge; the lodestone is of a trapezoid shape provided with arc bottom edges and asymmetric beveled edge and is provided with a magnet yoke ring in-circle end face; the lens supporter is arranged on the in-circle end face, the external diameter is matched with the internal diameter of the circular vertical convex edge of the magnet yoke ring; a front frame and a back frame, a supporter and a foundation are all made from engineering plastics by injection moulding; in the invention, electromagnetic induction force is remarkable improved, further product microminiaturization can be facilitated at high assembly accuracy and assembly efficiency.

Owner:NINGBO JCT ELECTRONICS

Metal armouring rigid coaxial cable

ActiveCN101150001AHigh tensile strengthGood flexural modulusCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsReliable transmissionElectrical conductor

This invention relates to a metallic armored rigid coaxial cable including an inner conductor, a dielectric layer, an outer conductor and an outer jacket characterizing that the inner conductor is oxygen-free copper wire, the dielectric layer is formed by step cylindrical blocks in series matched in convexes and concaves of heads and tails made of multiple sets of polysulfone, polyethersulfone, polyimide and PEEK engineering plastics, the outer conductor is oxygen-free copper pipe and the jacket is made of the engineering plastics. Advantages: reliable transmission, high mechanical performance, anti-radiation, anti-aging, fire and good in air-tightness.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

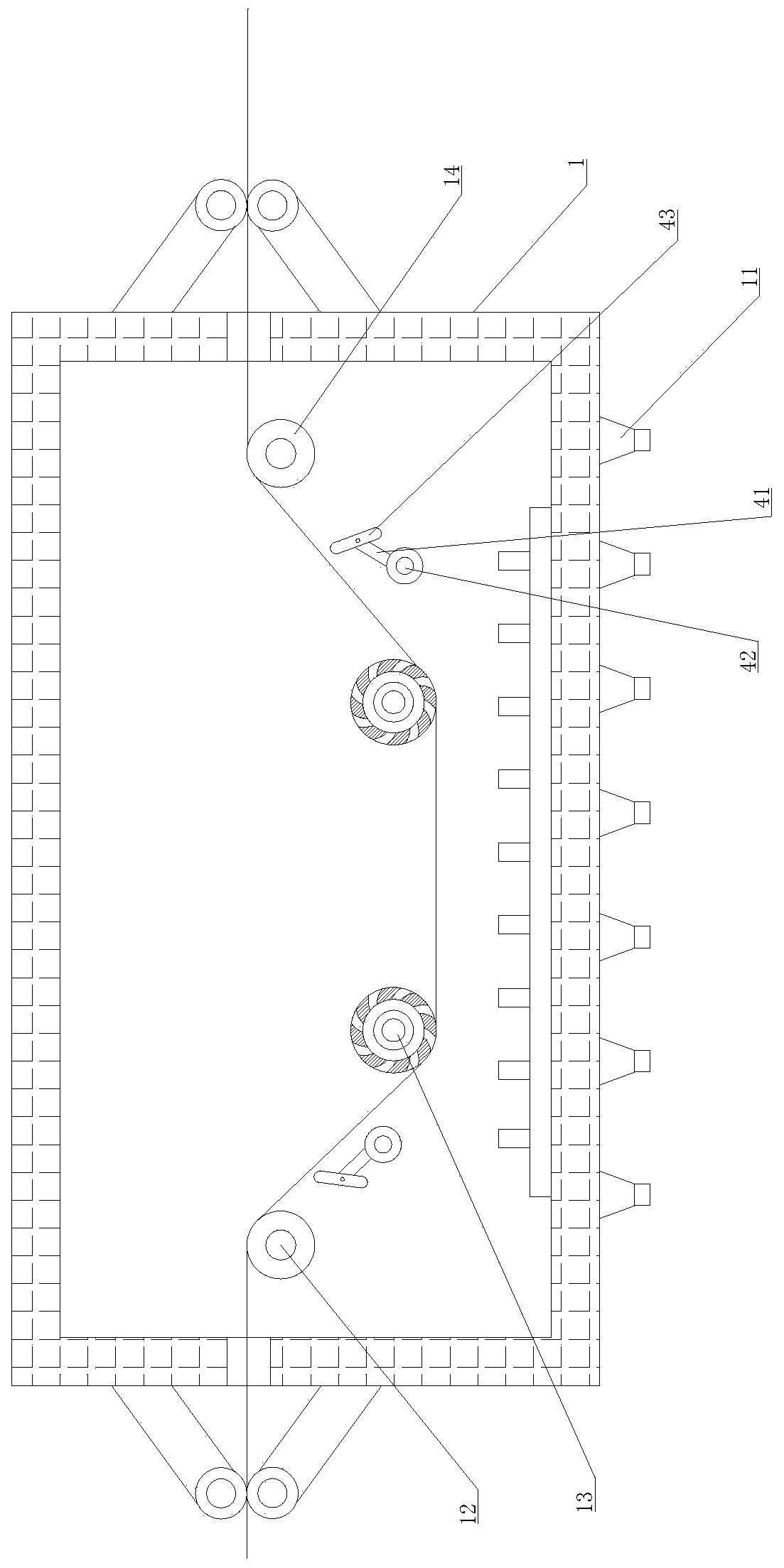

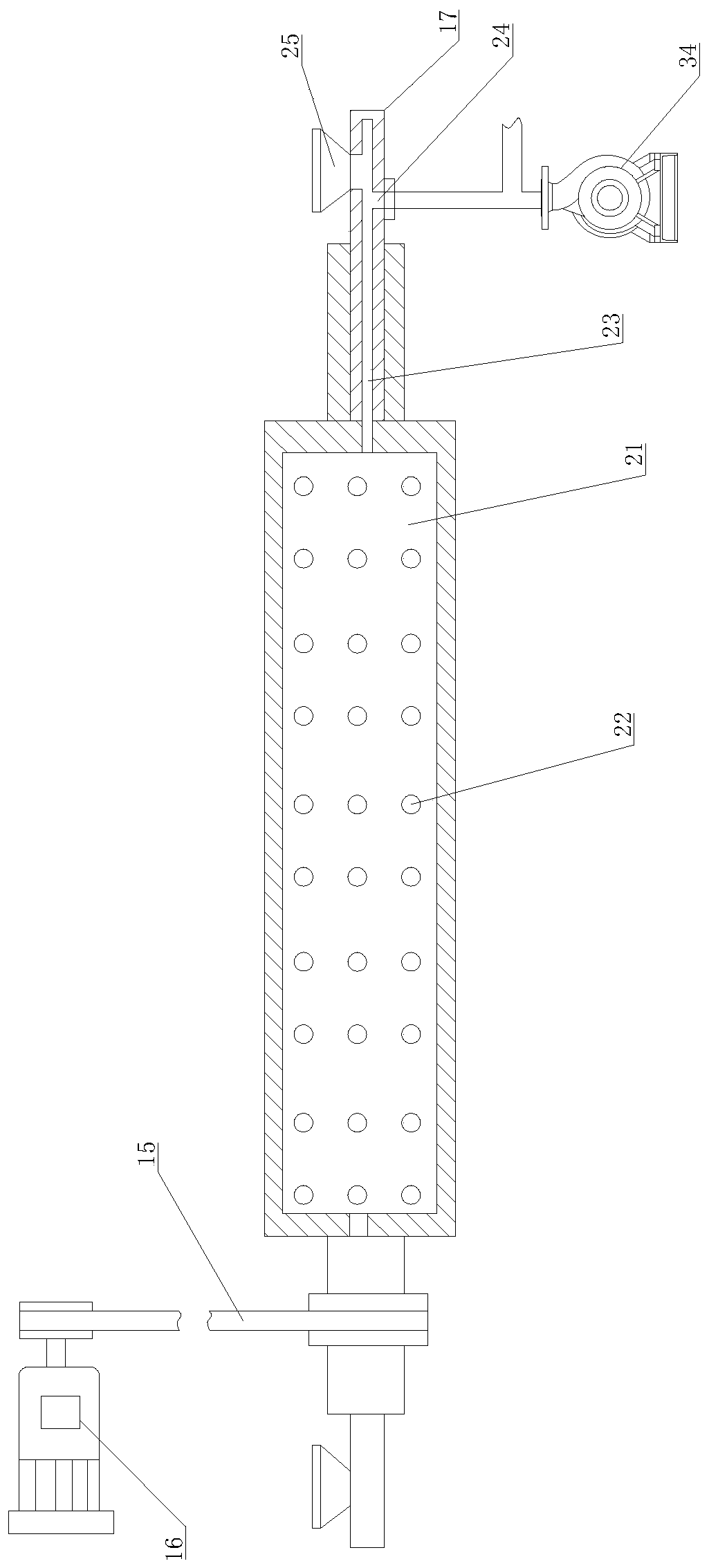

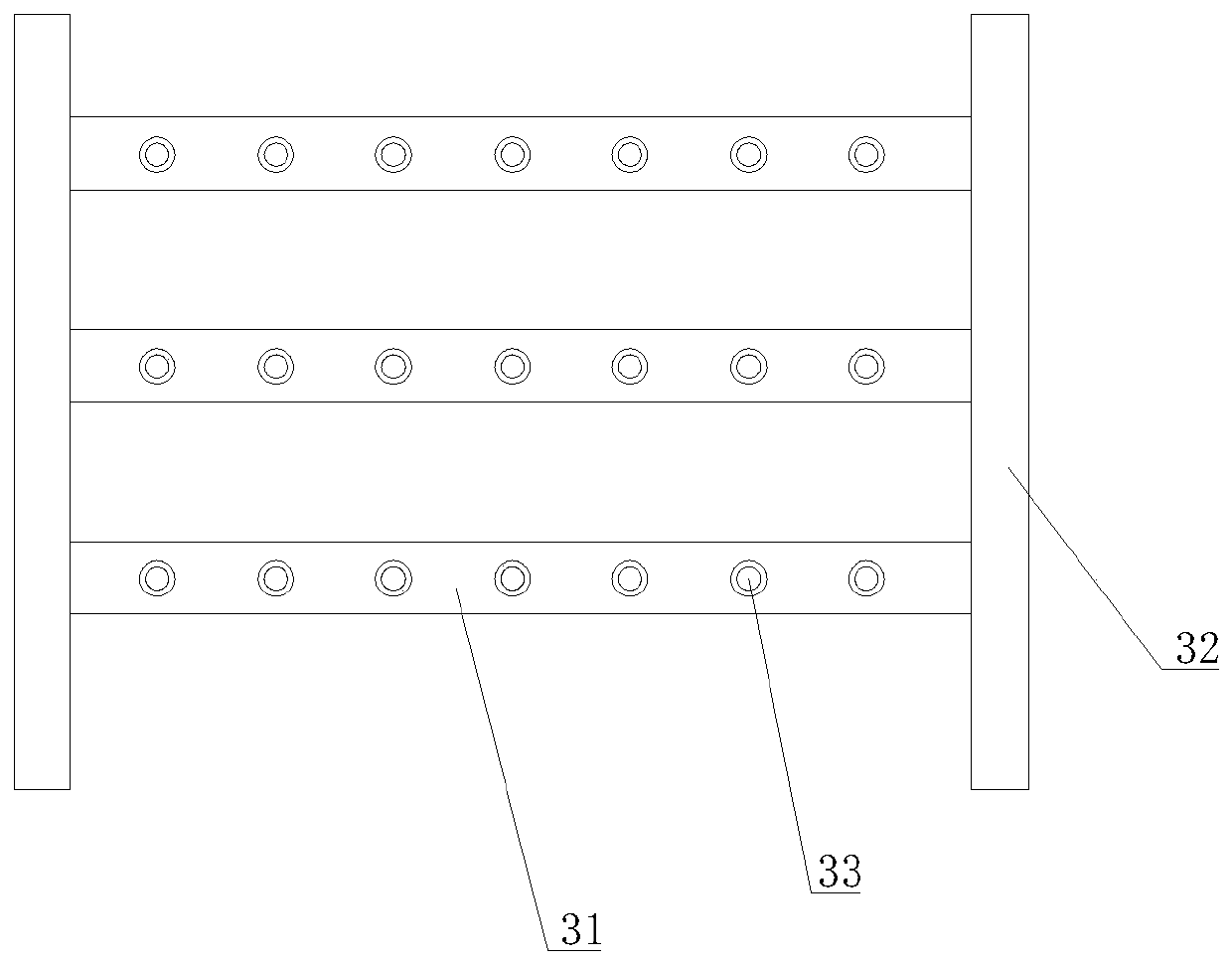

Radial tire ring traveler component and preparation technique

The invention discloses a meridian tire wire loop component and the manufacturing process thereof. Rubber base material, an anti-aging system, a reinforcement system, an adhesion system, a vulcanizing system and radio sensitizer are mixed in proportion to make a mixture. The rubber mixture is compounded in a banbury mixer. Glue is applied on a coppered steel wire based on the manufacturing technology of the tire wire loop to make the glue-coated steel wire band for meridian tire. An electron accelerator is used for producing a beam current to irradiate the glue-coated steel wire band of the meridian tire under the effect of a constant tension traction apparatus. The meridian tire wire loop component is vulcanized under the condition of luminous irradiation. After being irradiated, the crude rubber of the meridian tire wire loop component has strong Green strength and stable structural size and performance. Furthermore, steel wire withdrawal force is improved and the adhesive strength of the adhesive layer of a steel wire loop is enhanced, so the quality of a tire is improved. In addition, irradiation dose is small, the manufacturing cycle of products is shortened and production efficiency is high, thus being beneficial to environmental protection.

Owner:BEIJING RADIATION APPL RES CENT +1

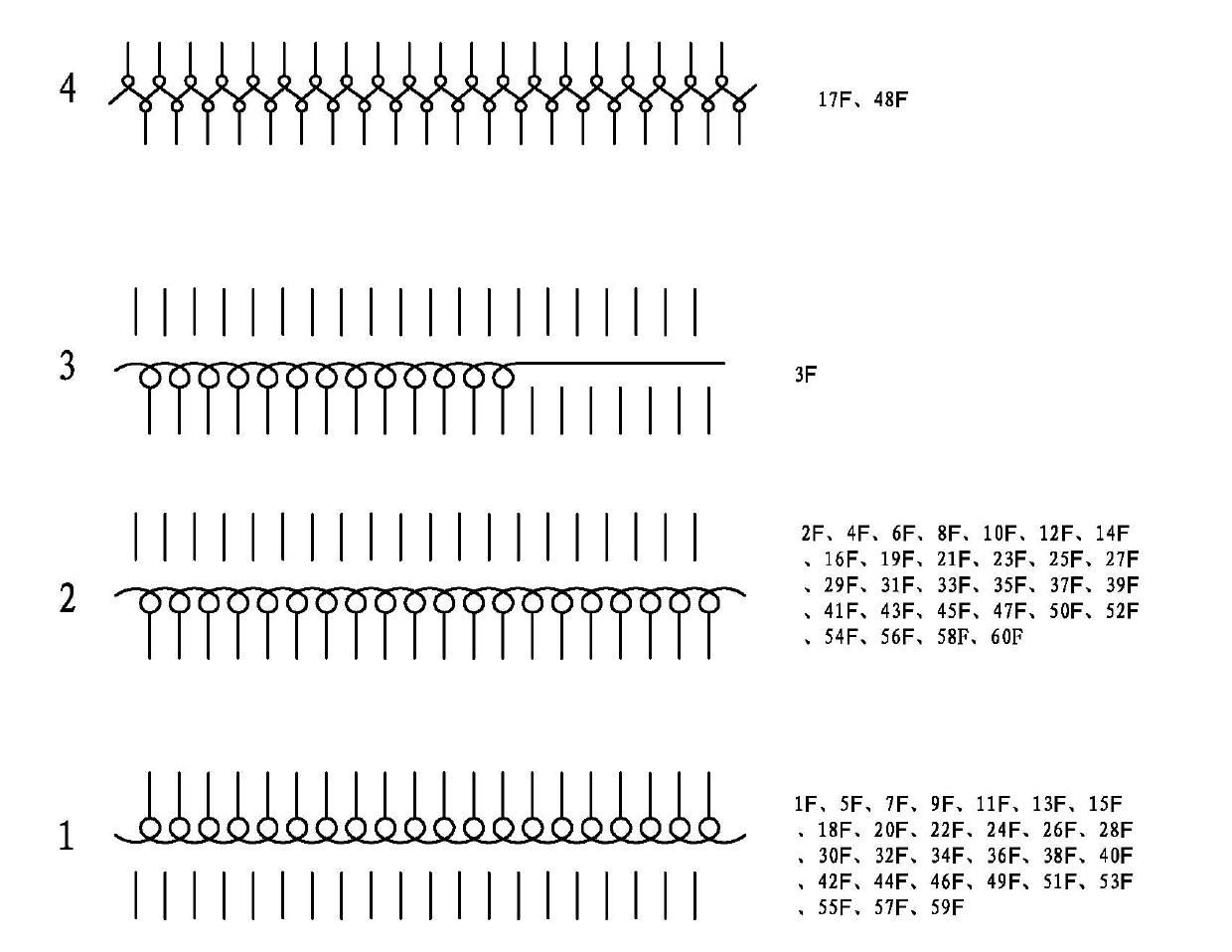

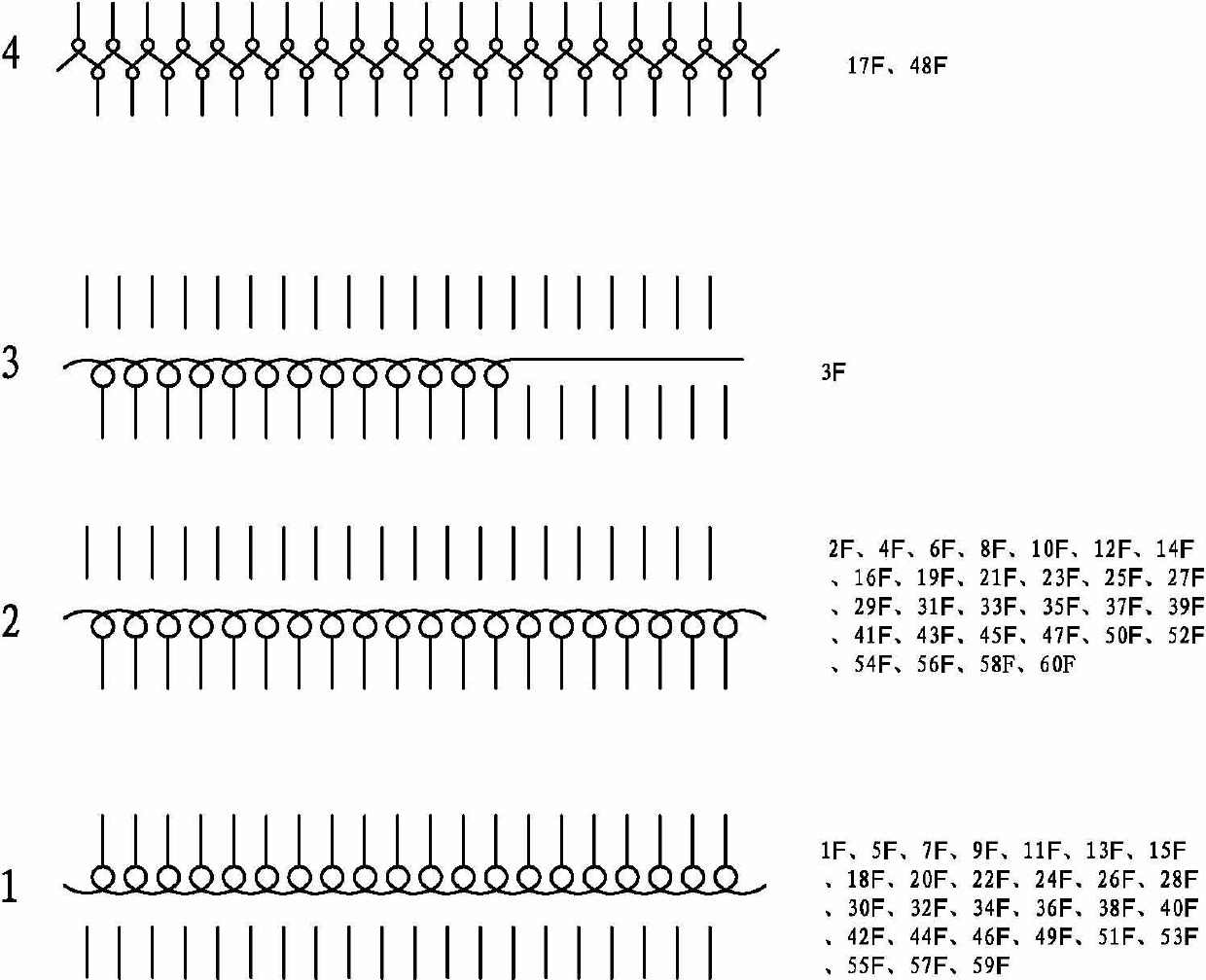

Fabric with eyed structures and weaving process thereof

InactiveCN102182003AReduce manufacturing costSimple weaving processWarp knittingLiquid/gas/vapor textile treatmentSoluble fiberIndustrial engineering

Owner:DONGGUAN TEXWINCA HLDG

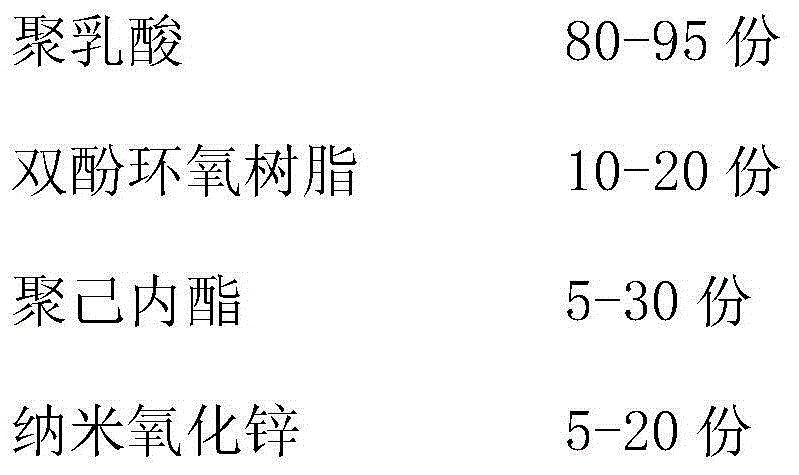

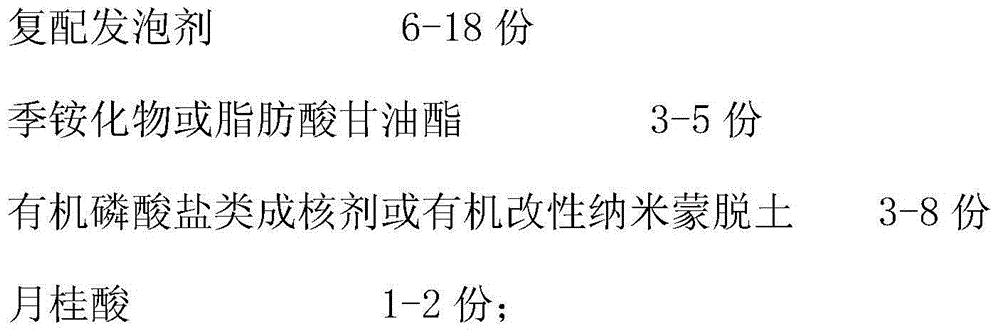

Nano zinc oxide modified foaming material and preparation method thereof

InactiveCN104861602AConductiveImprove mechanical propertiesAmmonium compoundsFatty acid glycerol esters

The invention discloses a nano zinc oxide modified foaming material. The nano zinc oxide modified foaming material comprises components in parts by weight as follows: 80-95 parts of polylactic acid, 10-20 parts of bisphenol epoxy resin, 5-30 parts of polycaprolactone, 5-20 parts of nano zinc oxide, 6-18 parts of a compound foaming agent, 3-5 parts of a quaternary ammonium compound or fatty glyceride, 3-8 parts of an organic phosphate nucleating agent or organically modified nano-montmorillonite and 1-2 parts of lauric acid. According to the nano zinc oxide modified foaming material, the process is simple and easy, and the polylactic acid based composite foaming conductive material with excellent conductivity and general mechanical performance, good heat resistance and controllable density can be prepared economically and effectively.

Owner:周末

Thermoplastic composite board and manufacturing method thereof

ActiveCN102555315AEquivalent mechanical strengthQuite rigidLaminationLamination apparatusUltimate tensile strengthThermoplastic composites

The invention discloses a thermoplastic composite board and a manufacturing method thereof. The thermoplastic composite board has set lateral width, longitudinally and continuously extends, and is coiled into a roll or is cut into blocks. The thermoplastic composite board comprises an enhanced skeleton, wherein a thermoplastic material layer is covered out of the enhanced skeleton. The manufacturing method comprises the following steps: (1) leveling the surface bend of the continuously-conveyed enhanced skeleton, and carrying out unoiling and derusting processing; (2) heating the enhanced skeleton, coating conglutinant resin material, and forming a binding layer after the conglutinant resin material is solidified; (3) conveying the enhanced skeleton to a formed mould, extruding the thermoplastic material, and successively coating out of the binding layer to obtain the board; and (4) shaping the board to obtain the thermoplastic composite board. The thermoplastic composite board disclosed by the invention has equivalent strength and rigidity and equivalent buffer performance, and can achieve good safety protection effect. The manufacturing method has the advantages of high production efficiency, simple technology and low production cost.

Owner:华瀚管道系统科技有限公司

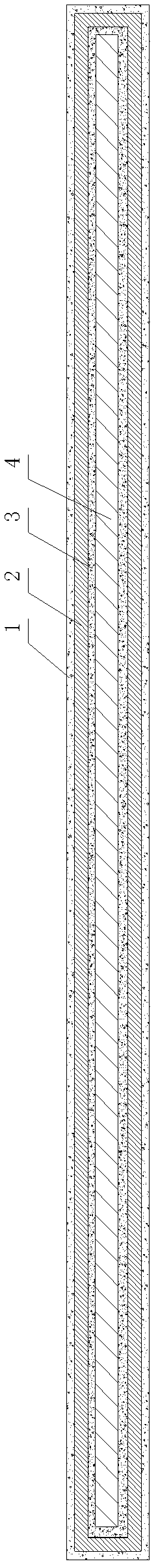

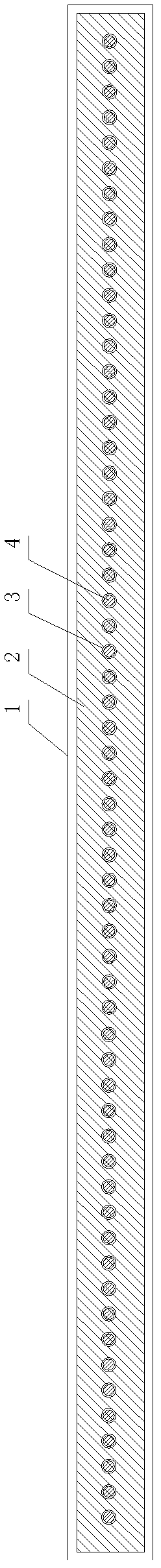

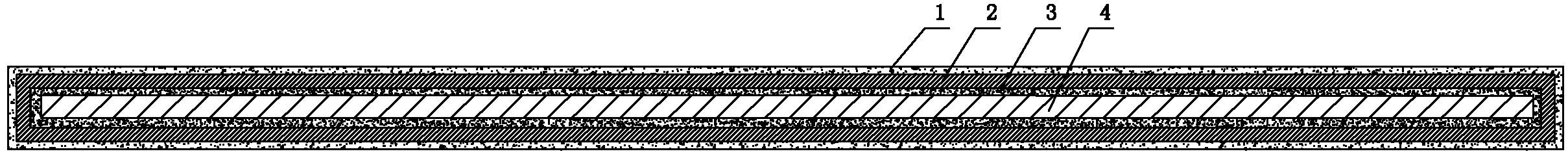

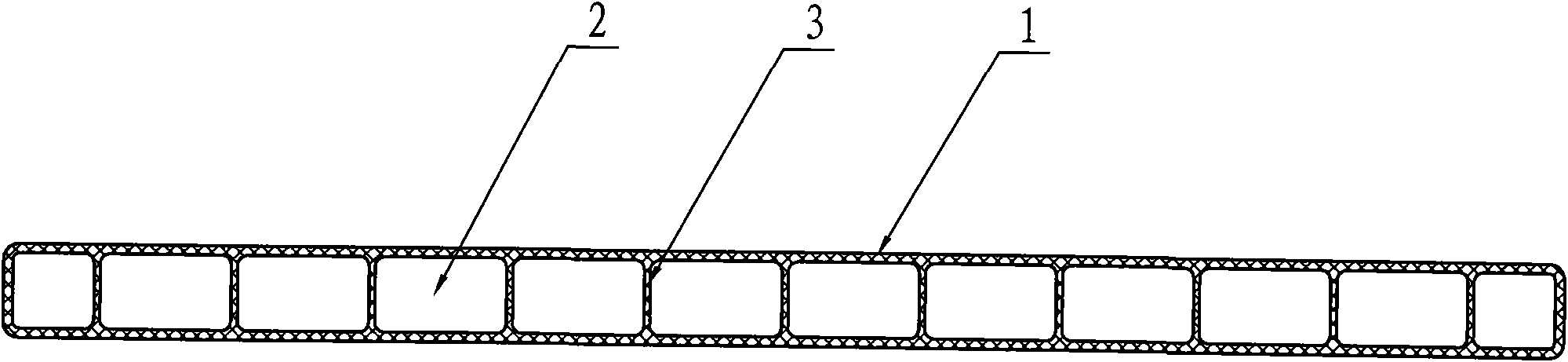

Cooling tower antifreezing macromolecule wind screen

InactiveCN101881573ANo pollution in the processDimensionally stable structureTrickle coolersGlass fiberCooling tower

The invention discloses a cooling tower antifreezing macromolecule wind screen which is a hollow board structure and composed of peripheric wall body, a hollow groove and a reinforcing rib, wherein the thickness of the peripheric wall body is 2-4 mm, and the thickness of the reinforcing rib is 2-5 mm; the width of the wind screen is 300-500 mm, and the thickness is 15-50 mm; the wind screen is made of macromolecule plastics or glass fiber reinforced plastics; The wind screen with the structure can be extruded and shaped by an extruder, has stable structure and size, high mechanical strength, light dead weight, light operation, strong loading capacity, excellent mechanical property, no environment pollution, high production mechanization degree and low cost, can be recovered and reused and is tidy and beautiful.

Owner:常州金坛塑料厂

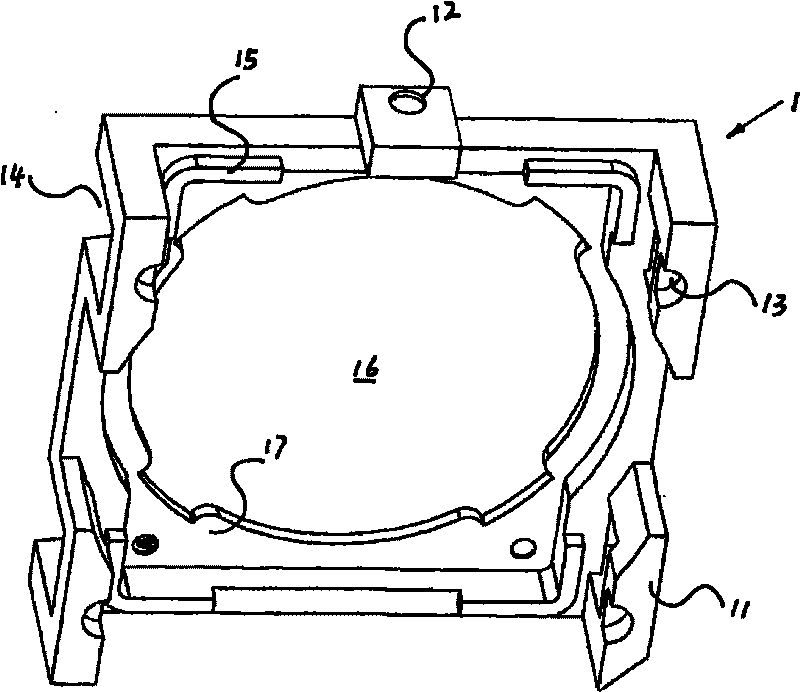

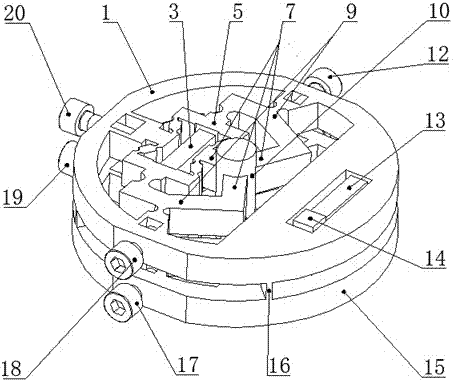

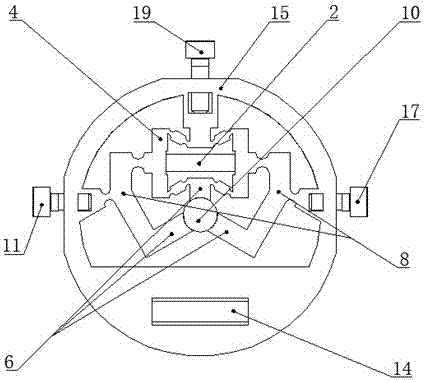

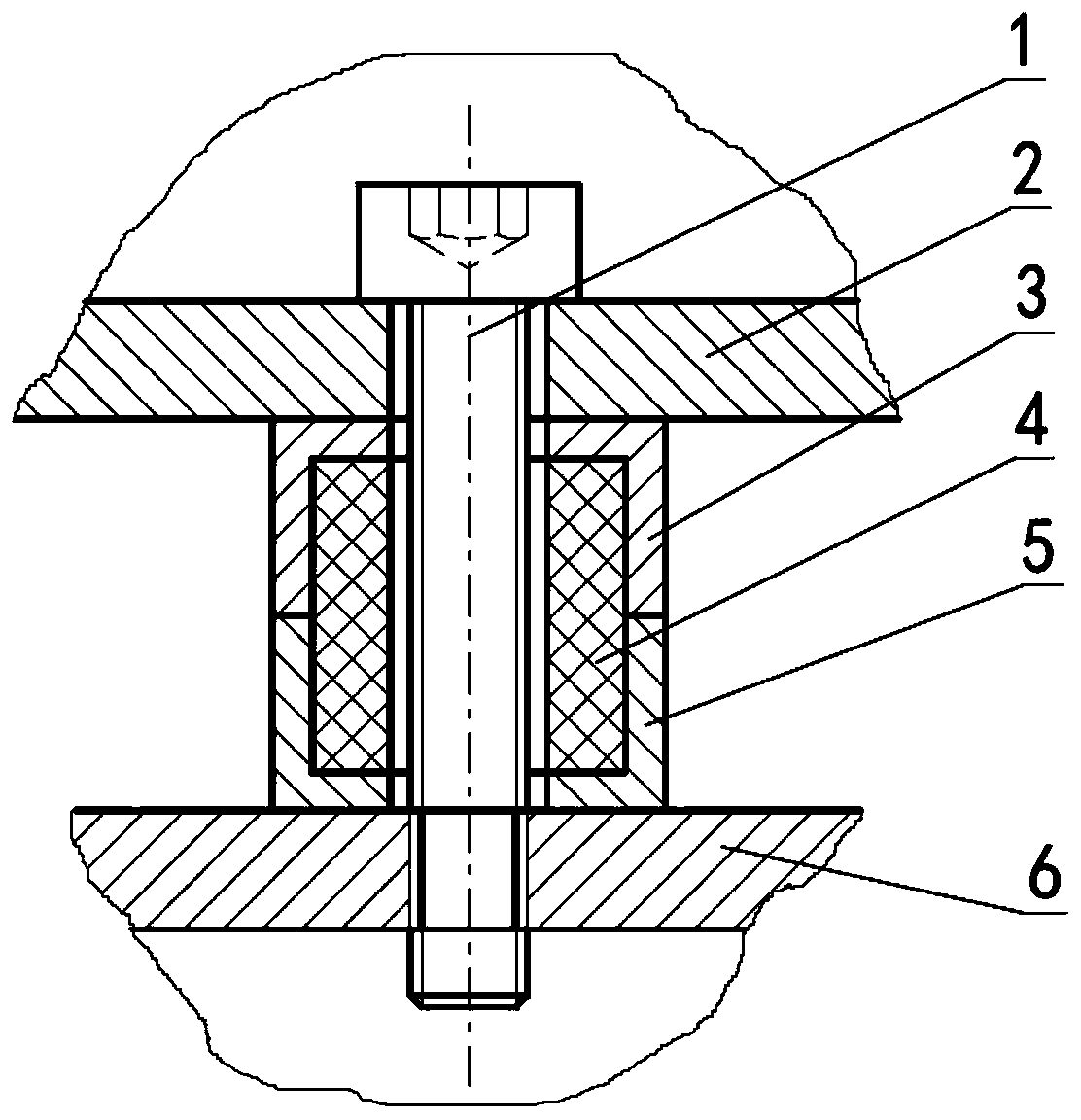

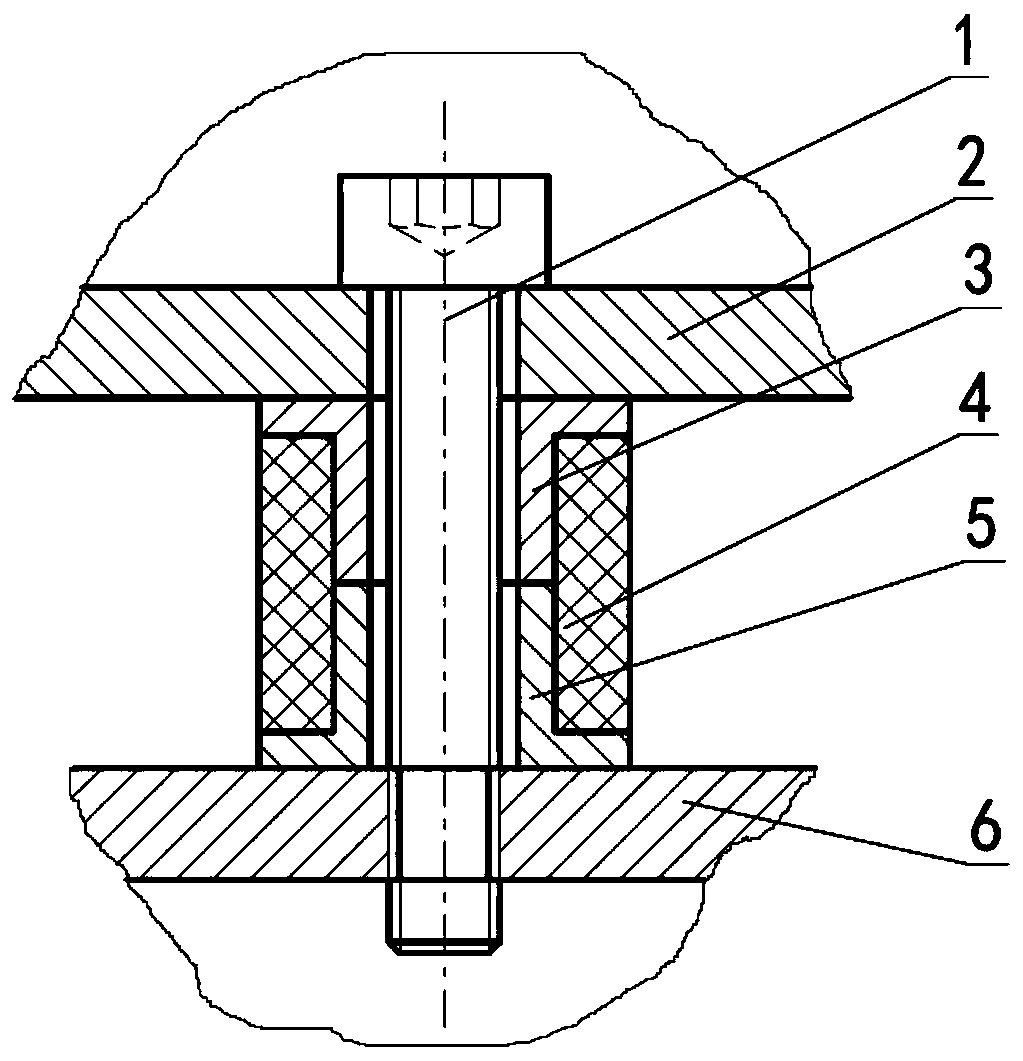

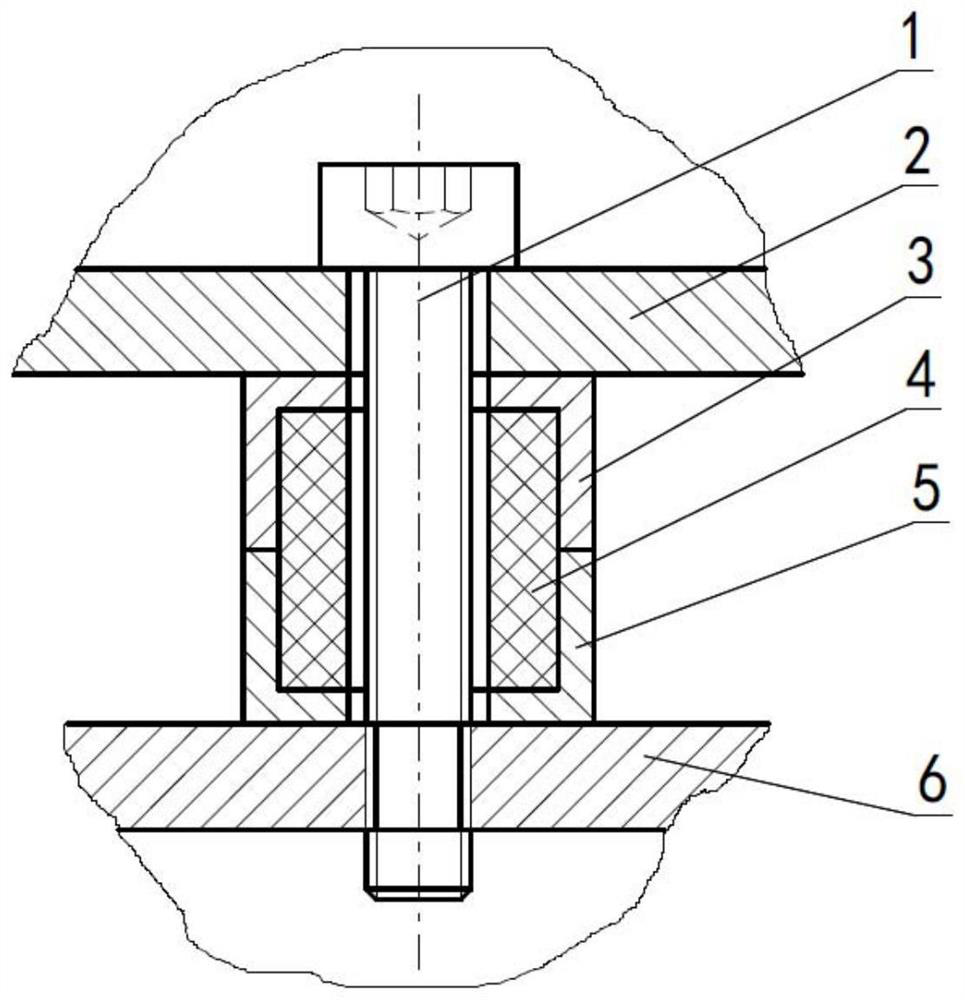

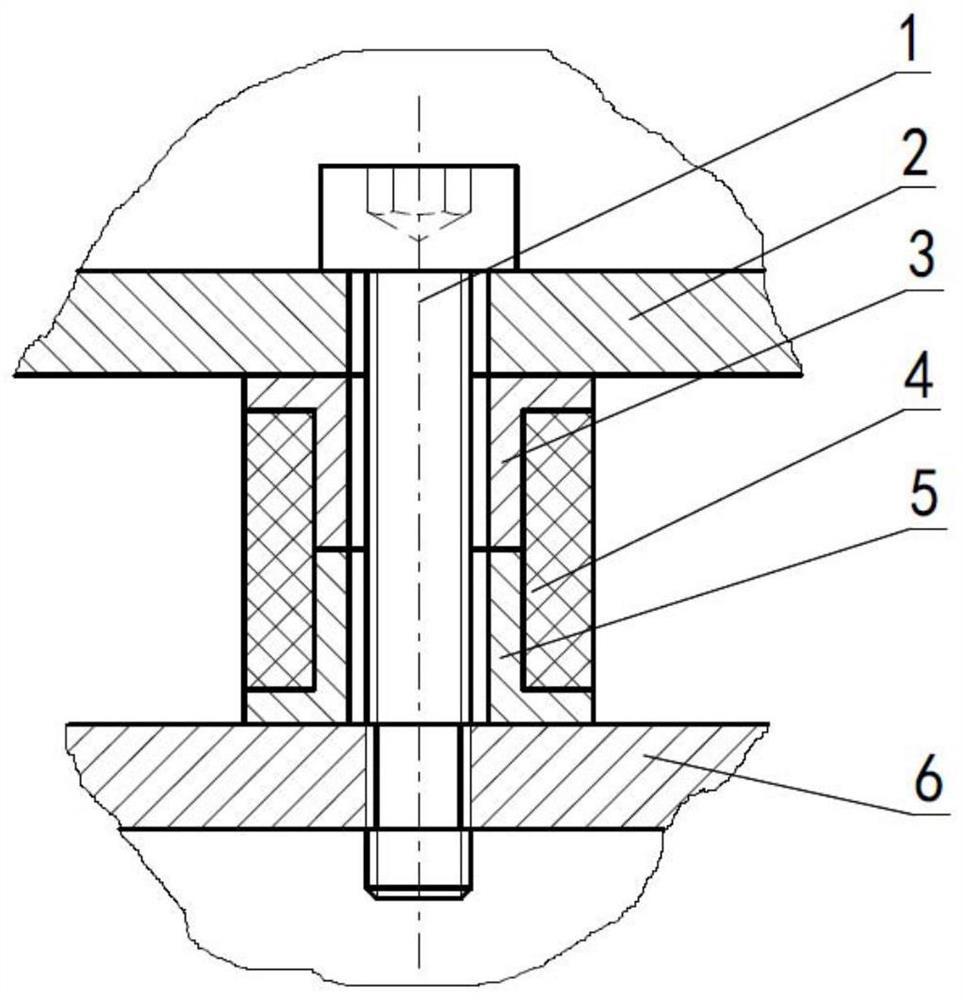

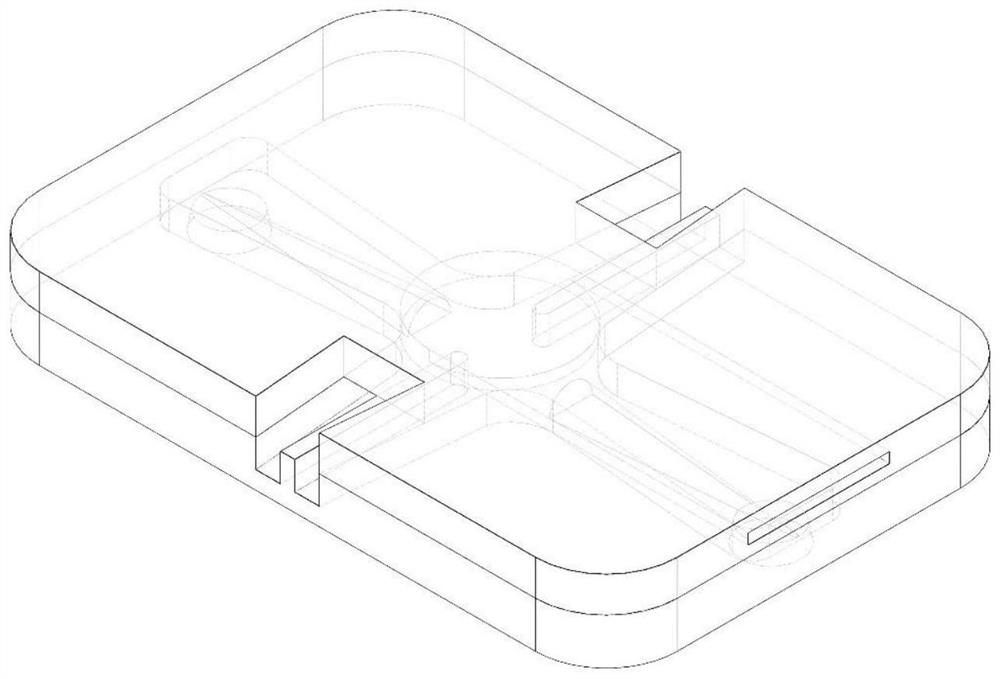

Inchworm-type rotary piezoelectric actuation platform

ActiveCN107086813AHigh working reliabilityReduce in quantityPiezoelectric/electrostriction/magnetostriction machinesEngineeringElectrical drive

The invention relates to an inchworm-type rotary piezoelectric actuation platform and belongs to the field of precision actuation. A rotor unit is a cylinder for outputting rotary displacement. An upper clamping unit is composed of a piezoelectric stack, a stator upper layer equipped with a three-jaw self-centering structure flexible hinge, and a preloading bolt. When elongating, the piezoelectric stack can enable the stator upper layer to clamp a rotor. A lower clamping unit is the same as the upper clamping unit in structure, and is composed of a piezoelectric stack, a stator lower layer equipped with a three-jaw self-centering structure flexible hinge, and a preloading bolt. When elongating, the piezoelectric stack can enable the stator lower layer to clamp the rotor. A driving unit is composed of a piezoelectric stack and an auxiliary driving block, and can achieve the step motion of the rotor. The stator upper layer and the stator lower layer are connected through a straight-type flexible hinge. The inchworm-type rotary piezoelectric actuation platform is simple in structure, low in cost, easy to control, stable and reliable in operation, and large in stroke.

Owner:JILIN UNIV

Solid oxide fuel battery anode and its production

Owner:UNIV OF SCI & TECH OF CHINA

Heat insulation pad

ActiveCN110356591AIncrease stiffnessAchieve high thermal resistanceCosmonautic vehiclesCosmonautic thermal protectionTitanium alloyComposite structure

The invention provides a heat insulation pad. The heat insulation pad is positioned between a low-temperature assembly and a high-temperature assembly, and comprises an upper titanium alloy cap, a polyimide column and a lower titanium alloy cap; a structure can be realized by embedding the polyimide column into the upper titanium alloy cap and the lower titanium alloy cap, and can also be realizedby embedding the upper titanium alloy cap and the lower titanium alloy cap in the polyimide column, and are fixedly connected through screws, when in a unstressed mode, a gap is reserved between theupper titanium alloy cap and the lower titanium alloy cap, and a gap value between the upper titanium alloy cap and the lower titanium alloy cap is 0 after the screws are screwed according to the 80%pre-tightening force. The heat insulation pad provided in the application adopts the heat insulation pad with a titanium alloy and polyimide composite structure, the rigidity is provided through the titanium alloy, the structure size is kept stable, thermal resistance is provided through polyimide and a separation interface, and finally large thermal resistance, high rigidity and high size stability of the heat insulation pad are realized.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Preparation method of composite door sheet

InactiveCN107866889ASave resourcesDimensionally stable structureLaminationLamination apparatusAdditive ingredientComposite plate

The invention discloses a method for preparing a composite door panel. The operation steps are as follows: (1) cutting: decontamination treatment is performed on the raw materials, ingredients are prepared according to the requirements of the drawing, and the wooden frame, filler board and surface board are cut; (2) high temperature treatment : Carry out high-temperature treatment on the wooden frame, filler board, and surface board; (3) Thickness sanding; (4) Gluing and forming embryos; (5) Glue pressing: Send the slabs to the hot press, start the hot press, The temperature is controlled at 150°-170°, the compression time is 200s-300s, and the pressure is 4MPA-6MPA. After the hot pressing is completed, let it stand for 30-45min and remove the slab; (6) veneer the cooled slab Edge sealing, processing forming edge, processing assembly hole for assembly; (7) Spraying topcoat. The invention improves the preparation method, effectively prevents degumming and even warping of the composite board by controlling the moisture content of the composite board, and improves the appearance quality of the composite board.

Owner:胡征远

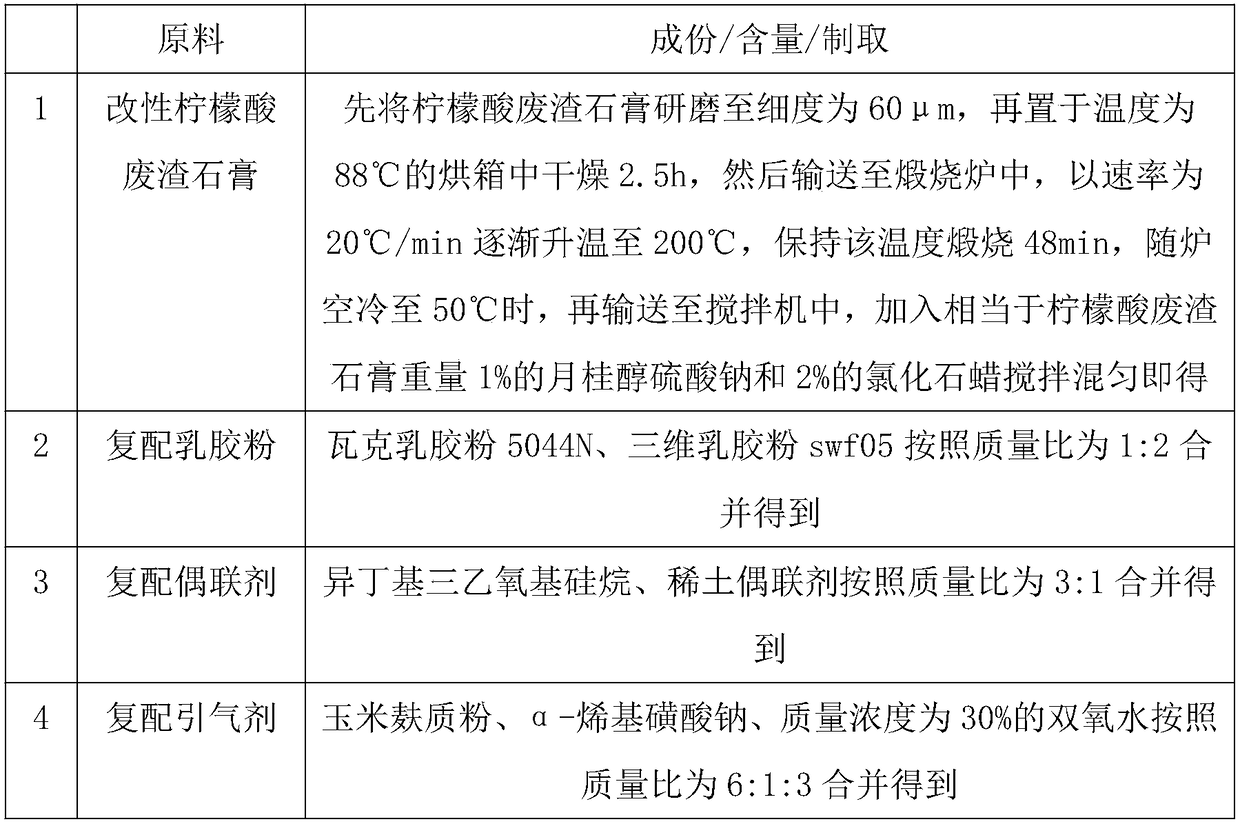

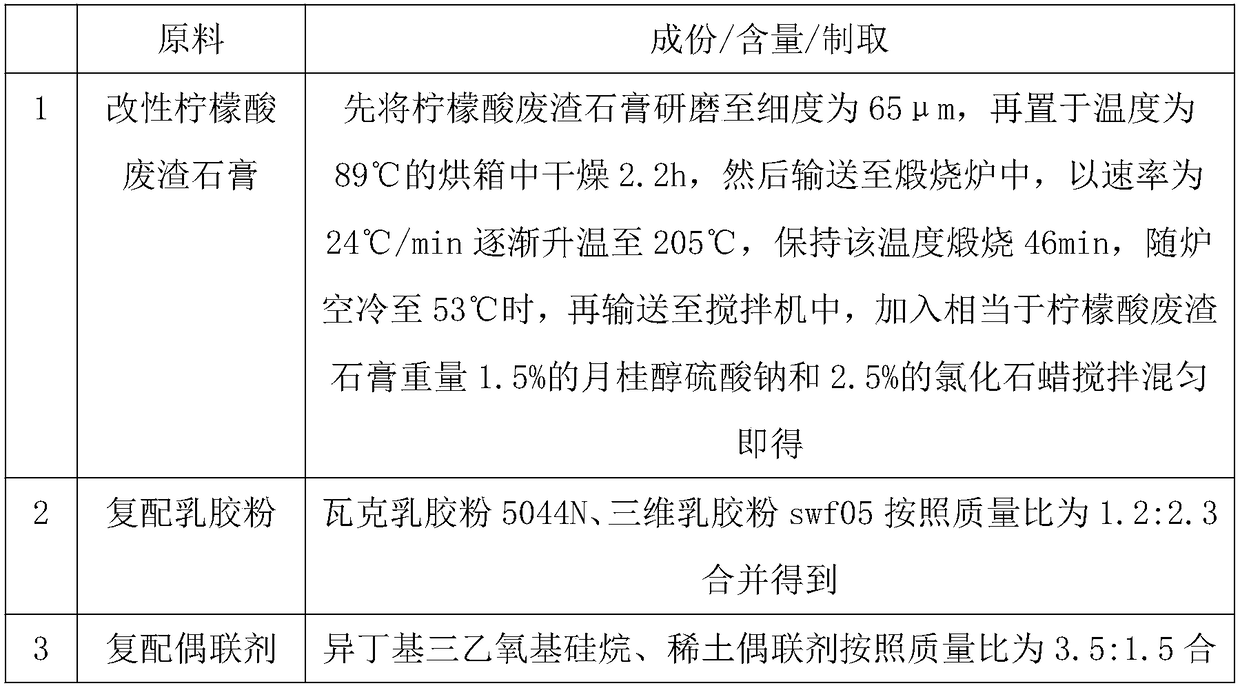

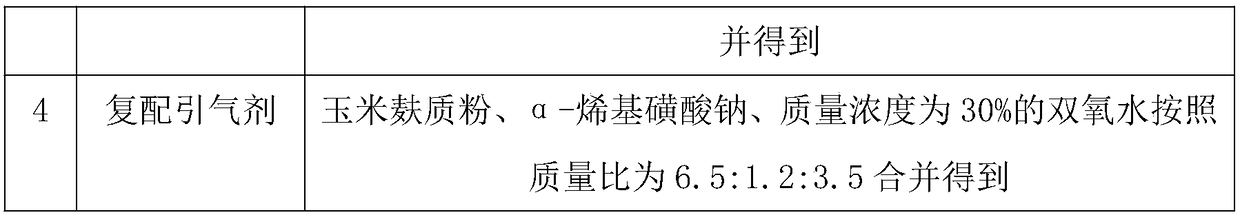

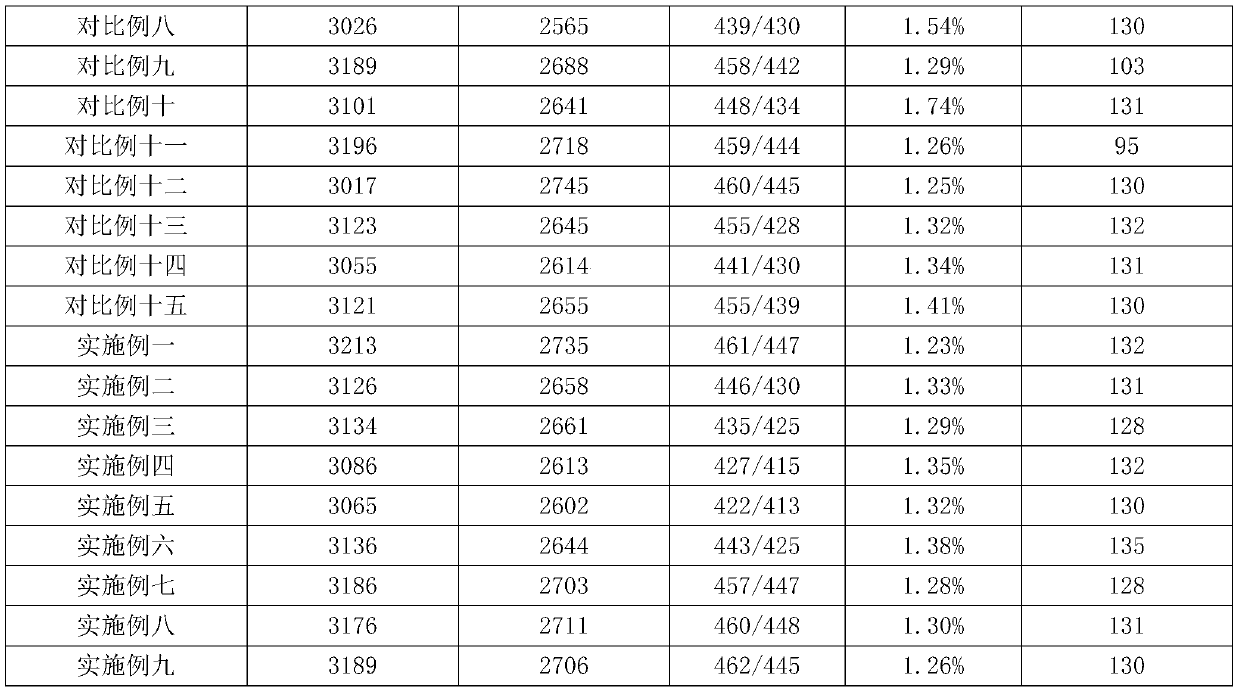

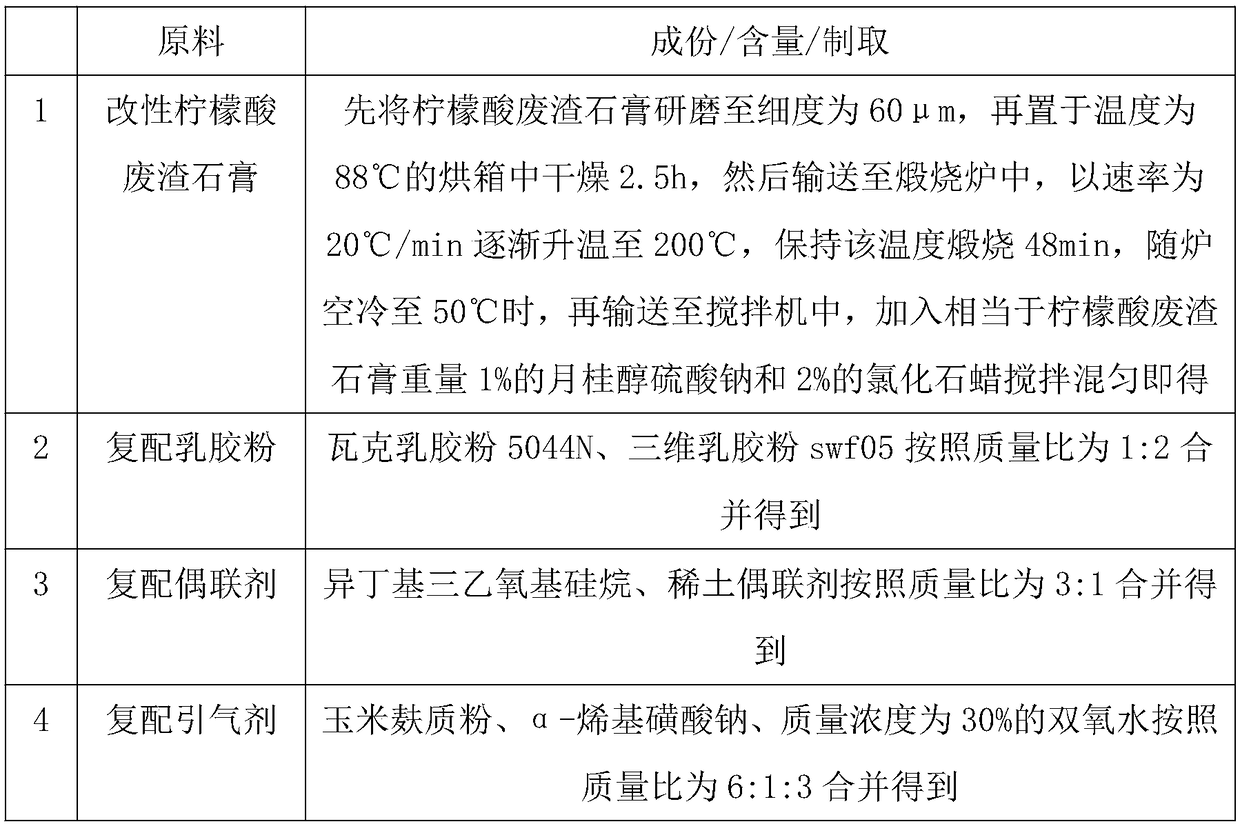

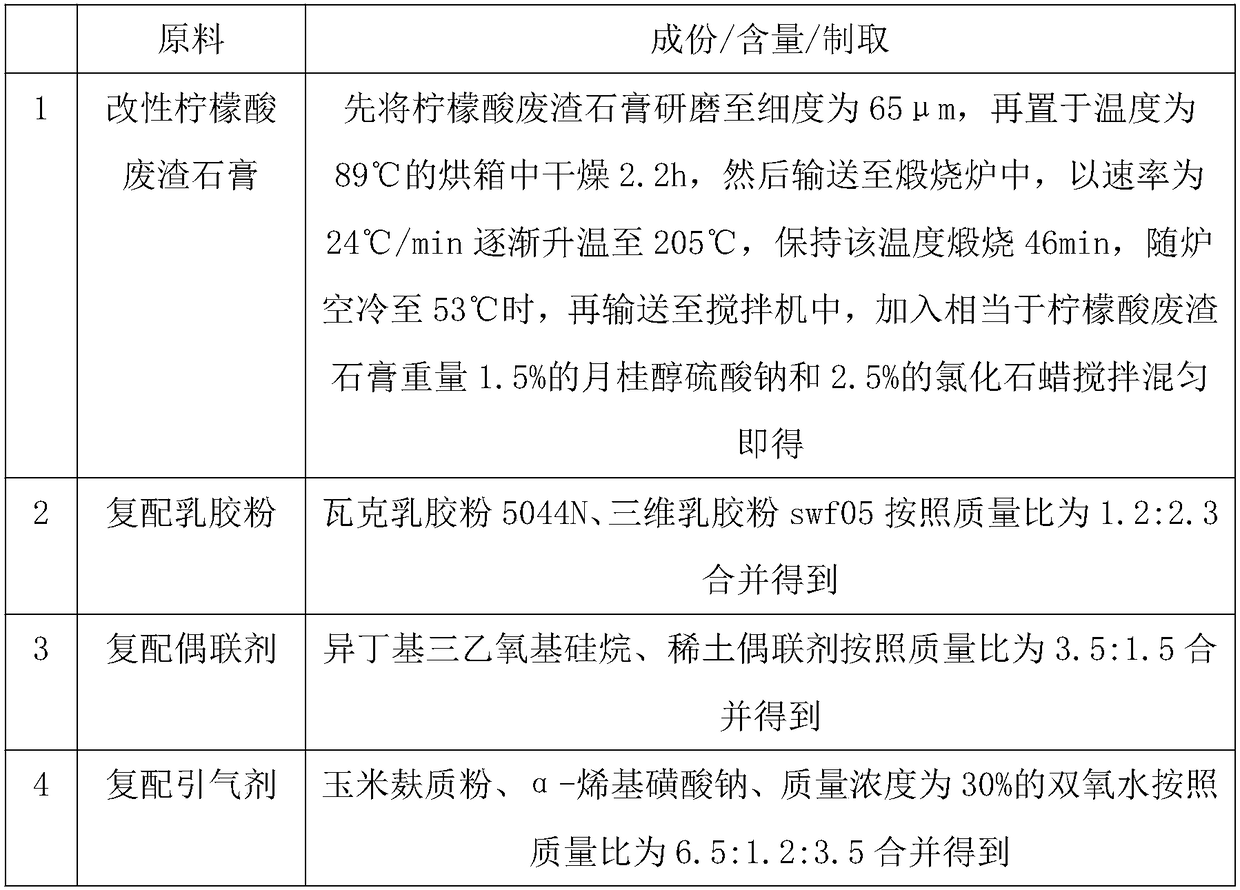

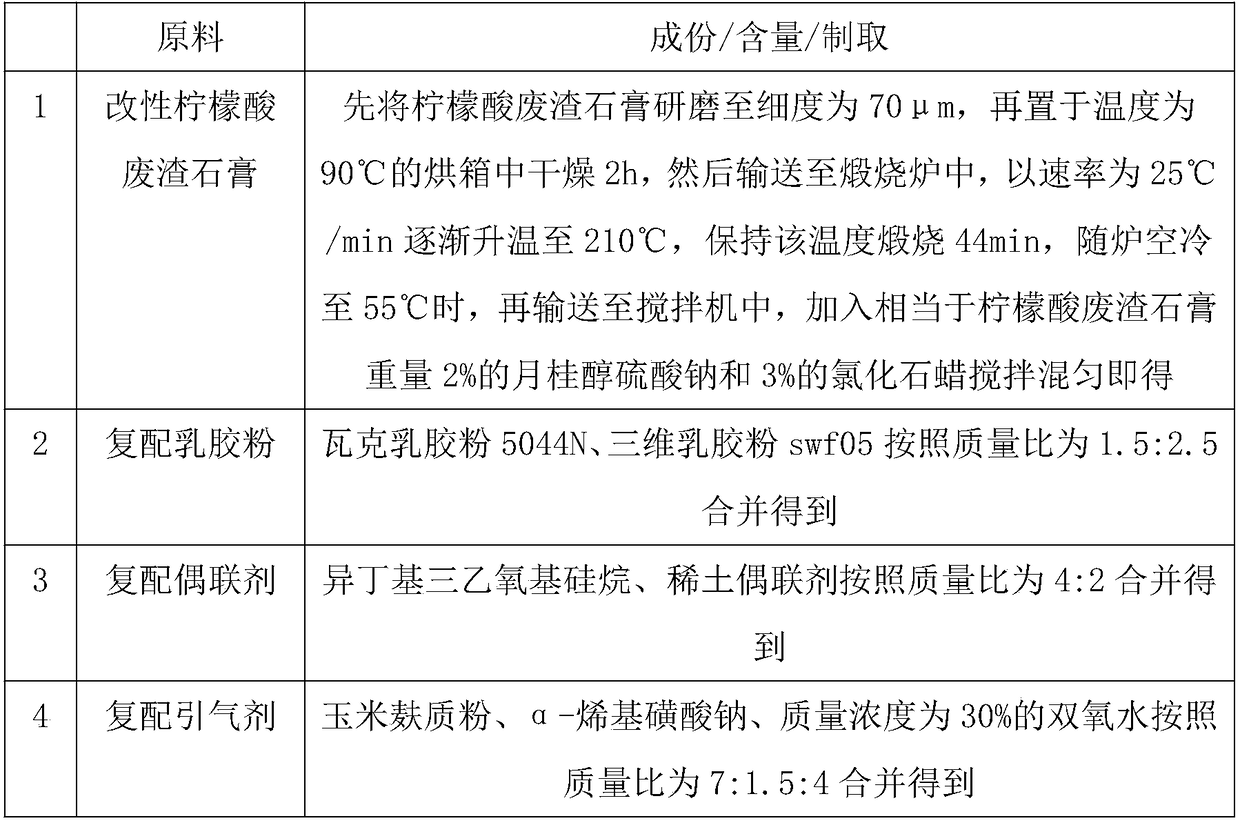

High-strength waterproof composite gypsum board

The invention discloses a high-strength waterproof composite gypsum board and relates to the technical field of building gypsum boards. The high-strength waterproof composite gypsum board comprises the following raw materials: modified citric acid waste residue gypsum, Wudalianchi volcano mud, rectorite powder, hexacyclic stone powder, a hibiscus manihot fiber, ferric trichloride, chlorogenic acid, a coumarone resin, compounded latex powder, a compounding coupling agent and a compound air entraining agent. The gypsum board disclosed by the invention has excellent mechanical strength, hydrophobicity, water resistance, heat storage and wave absorption, and compared with the prior art, the gypsum board is remarkably improved in property, good in application performance and practical and reliable and has very good popularization values.

Owner:合肥永泰新型建材有限公司

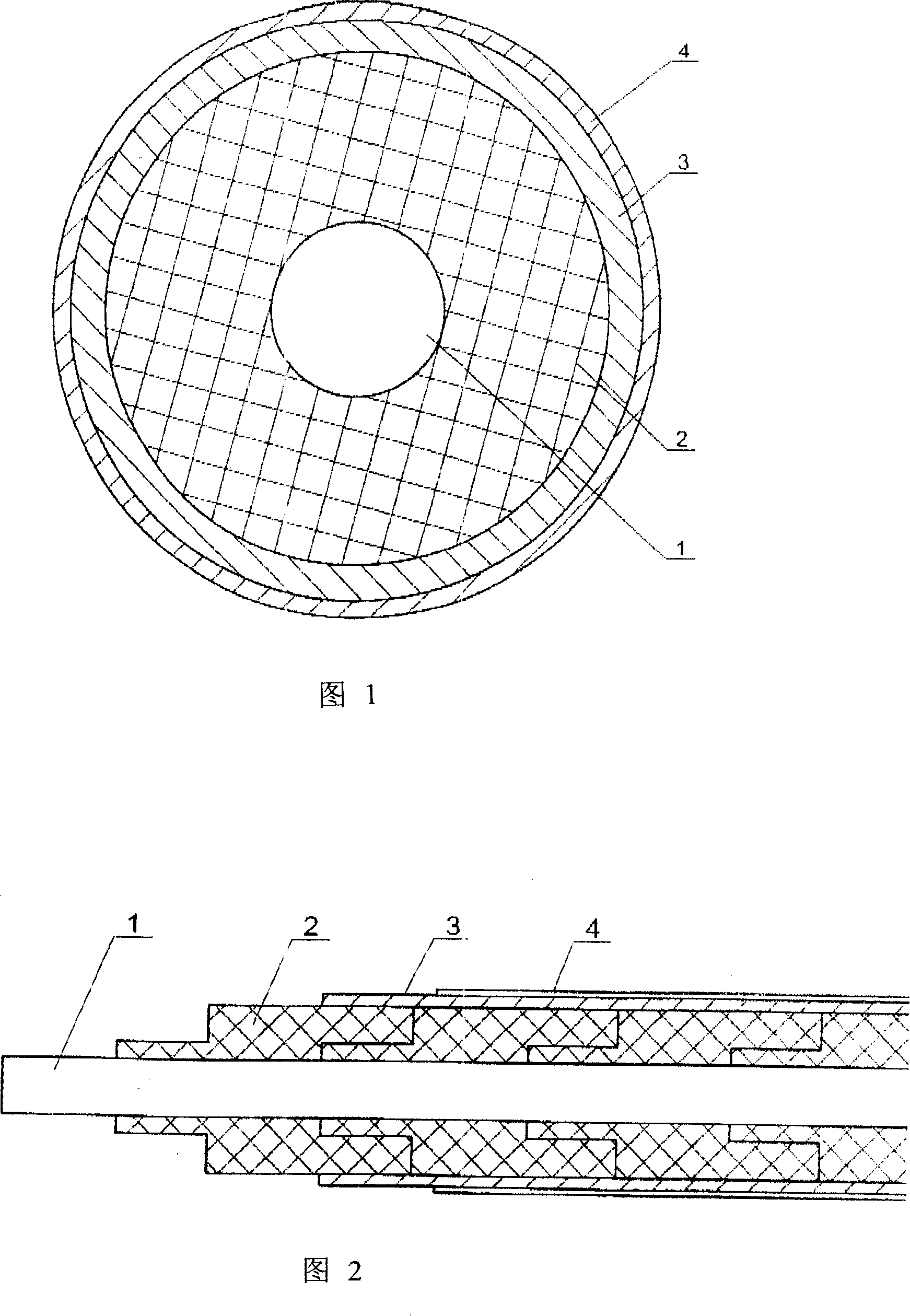

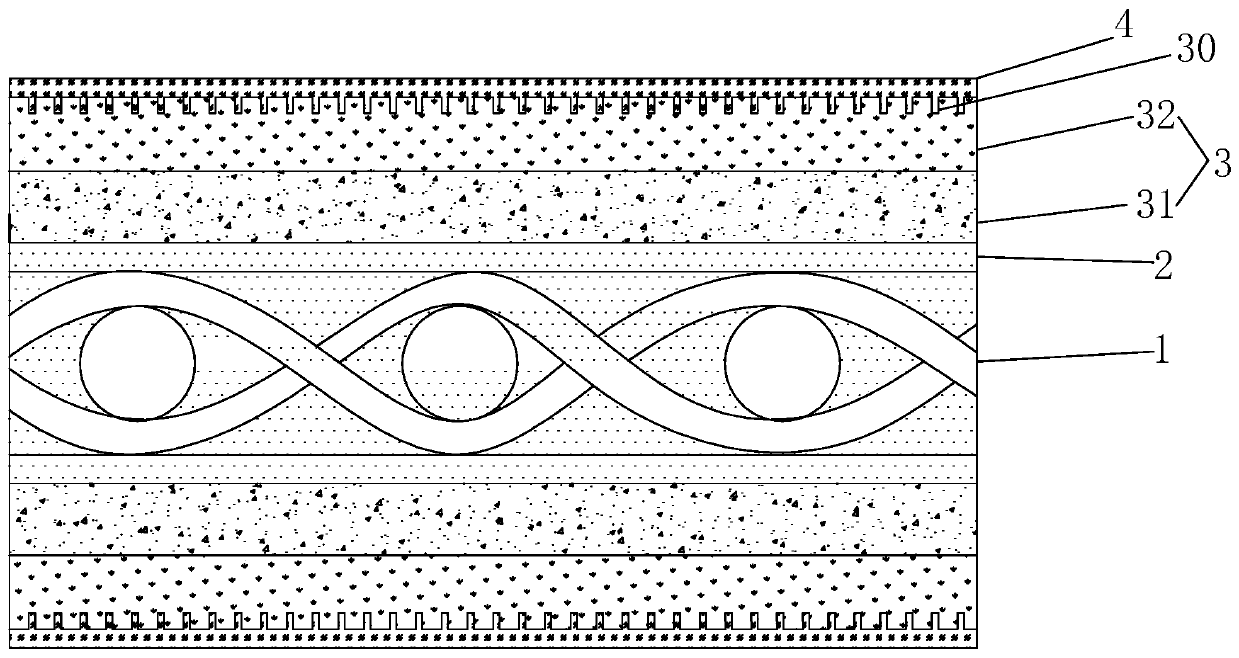

Self-cleaning membrane structure and preparation method thereof

ActiveCN111441178AImprove flame retardant performanceHigh tear strengthFibre typesCoatingsPolyesterPolymer science

The invention discloses a self-cleaning membrane structure and a preparation method thereof, and belongs to the field of building membrane materials. The self-cleaning membrane structure comprises a high-strength polyester fabric core layer, a strengthening layer, a polyvinyl chloride (PVC) function layer and a self-cleaning layer, wherein the PVC function layer comprises a creep-resistant layer and an anti-aging layer; and the strengthening layer is prepared from the following raw materials in parts by weight: 100 parts of polyvinyl chloride paste resin, 5 to 15 parts of polystyrene resin, 140 to 160 parts of dioctyl-phthalate (DOP), 2 to 8 parts of liquid rare-earth stabilizer, 2 to 6 parts of liquid isocyanate cross-linking agent, 6 to 15 parts of flame retardant, 1 to 5 parts of octylphenol polyoxyethylene ether, and 5 to 15 parts of OS-20 diluent. The self-cleaning membrane structure has the effects of better creep resistance, a better mechanical property and longer service life.The preparation method of the self-cleaning membrane structure comprises the steps of preparing raw materials; preparing the membrane layers: sequentially forming the strengthening layer, the creep-resistant layer and the anti-aging layer, and then plastifying; embossing; carrying out surface treatment to form the self-cleaning layer; embossing; and cooling to obtain the product. The product hasthe effects of better tear resistance and tension resistance, and higher membrane material peeling strength.

Owner:海宁市明德新材料有限公司

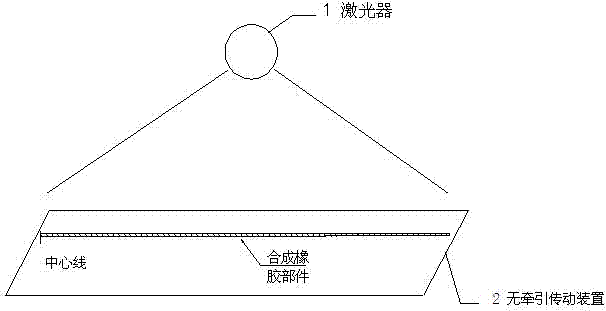

New method for crosslinking tire inner liner rubber material by laser technology

InactiveCN106867001ANo risk of radioactive radiationNo pollution in the processRubber materialLaser technology

The invention discloses a new method for crosslinking a tire inner liner rubber material by a laser technology; a tire prepared after the rubber material treated by the method is crosslinked and vulcanized has the advantages of stable inner liner layer forming structure size and performance, the rubber layer thickness is thinned, the adhesion strength is enhanced, the tire weight and energy consumption (lightweighting and energy conservation) are reduced, and the uniformity and dynamic balance of the tire are effectively improved.

Owner:BEIJING RES & DESIGN INST OF RUBBER IND

Bamboo polyester wool elastic plain weave dyeing process

InactiveCN110306371AReduce damageSafe to useDry-cleaning apparatus for textilesGrip property fibresPlain weaveChemistry

The invention discloses a bamboo polyester wool elastic plain weave dyeing process which includes the steps: a, desizing and bleaching a bamboo polyester wool elastic plain weave fabric to obtain a product A; b, cleaning and softening the product A by ultrasonic waves, adding fabric softening agents and water softening agents, and continuously softening the product A twice to obtain a product B; c, placing the product B into a dye coater, dyeing the product B with dye liquor at multiple stages, heating the product B to reach 40-60 DEG C, adding first dye liquor and performing ultrasonic insulation treatment at the first stage, heating the product B to reach 60-70 DEG C, adding second dye liquor and performing ultrasonic insulation treatment at the second stage, heating the product B to reach 70-90 DEG C, adding third dye liquor and performing insulation treatment at the third stage, cooling the product B to 30-40 DEG C and performing insulation treatment to obtain a product C; d, washing and soaping the product C to obtain a product D; e, softening the product D and performing loose finishing and drying to obtain a finished product. The bamboo polyester wool elastic plain weave dyeing process has the advantages of dyeing uniformity, high dye-uptake rate and color fastness.

Owner:湖州恒织源科技有限公司

Metal armouring rigid coaxial cable

ActiveCN100490022CHigh tensile strengthGood flexural modulusCoaxial cables/analogue cablesPlastic/resin/waxes insulatorsReliable transmissionElectrical conductor

This invention relates to a metallic armored rigid coaxial cable including an inner conductor, a dielectric layer, an outer conductor and an outer jacket characterizing that the inner conductor is oxygen-free copper wire, the dielectric layer is formed by step cylindrical blocks in series matched in convexes and concaves of heads and tails made of multiple sets of polysulfone, polyethersulfone, polyimide and PEEK engineering plastics, the outer conductor is oxygen-free copper pipe and the jacket is made of the engineering plastics. Advantages: reliable transmission, high mechanical performance, anti-radiation, anti-aging, fire and good in air-tightness.

Owner:NUCLEAR POWER INSTITUTE OF CHINA

a thermal insulation pad

ActiveCN110356591BIncrease stiffnessAchieve high thermal resistanceCosmonautic vehiclesCosmonautic thermal protectionThermal insulationTitanium alloy

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

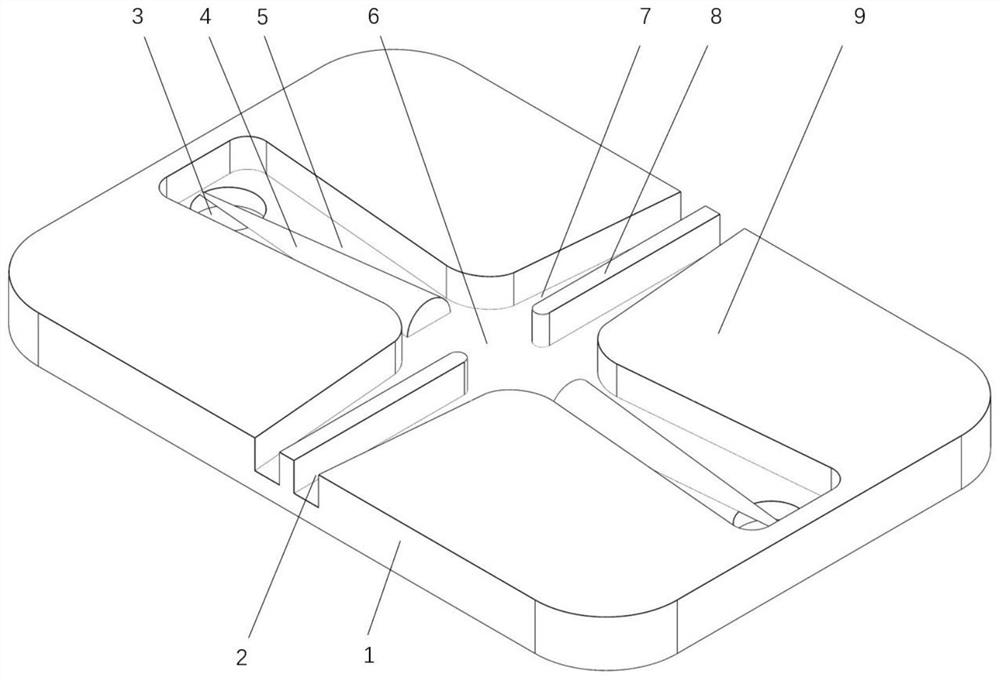

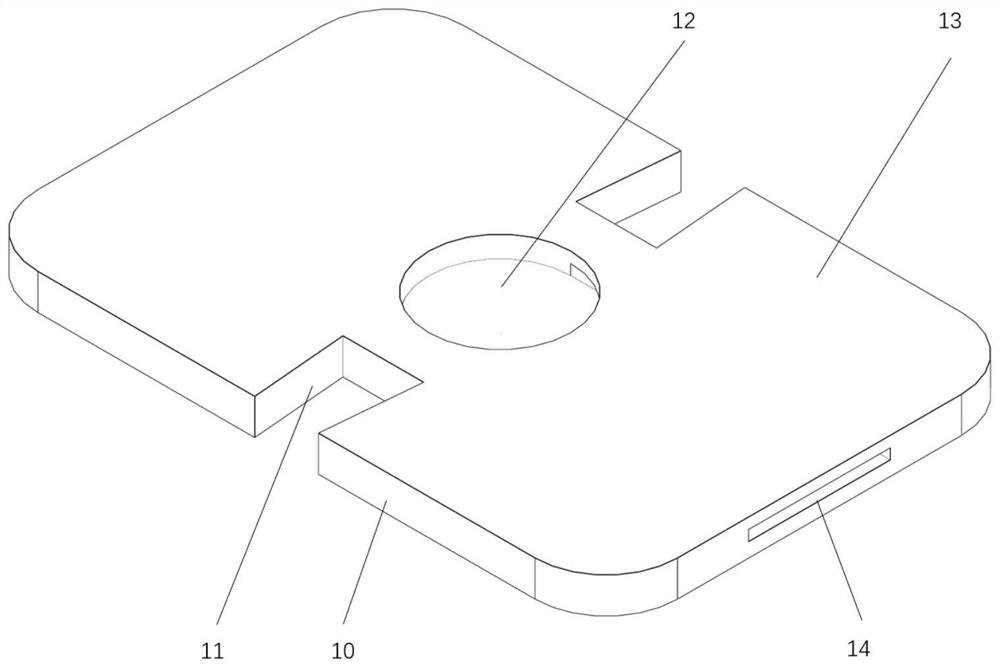

Wearable sweat self-driven active collection and discharge device

PendingCN114680945AFast transferImprove transmission efficiencySurgeryVaccination/ovulation diagnosticsExternal energyMedicine

The invention provides wearable sweat directional self-driven collecting and discharging equipment which can be used for real-time monitoring of sweat lactic acid, and particularly relates to bionic structure design and a preparation method of the wearable sweat directional self-driven collecting and discharging equipment. The bionic structure inspiration of the equipment comes from an unparallel plate structure of a beach beak and a conical structure of a pine needle. Sweat enters the channel from the bionic inlet, external energy input is not needed, and the sweat can directionally move to enter a detection area only by means of driving force difference generated by self-production of the structure. And a modified electrode plate of the electrochemical sensor is arranged above the detection area and can be used for specifically detecting the content of lactic acid in sweat. In order to accelerate separation of new sweat and old sweat, perspiration structures are arranged on the two sides of the detection area, and the sweat can be automatically discharged out of the detection area only through driving force generated by the structures. By means of the device, physical workers such as athletes and the like can noninvasively and conveniently detect the change of the content of lactic acid in the body in real time, so that the motion state is evaluated, meanwhile, the oxidative metabolism level can be reflected, and early warning is provided for lactic acid poisoning and pressure ischemia.

Owner:SUZHOU UNIV

Manufacturing process of radial tyre inner lining air barrier component

The invention discloses a a preparation technique for radial tire liner airtight layer part comprising lower layer substrate rubber and upper layer coating glue. A rubber substrate, an anti-aging system, a vulcanizing system and a radiation crosslinking sensitizer are mixed into a mixture in proportion; the rubber mixture is respectively mixed in an internal mixer and manufactured into the radial tire liner airtight layer part according to the production technique of the tire liner airtight layer part. A beam current generated by an electron accelerator is used for carrying out irradiation treatment on the tire liner airtight layer part on a lower device without a traction beam; under the condition of limited oxygen radiation, the radiation pre-curing treatment on the tire liner airtight layer part of the radial tire is accomplished. The liner airtight layer part treated by radiation of the invention has a high green intensity and a high bonding intensity, has stable structure size and performance, reduces the thickness of the rubber layer of the part, can improve the quality of the tire, saves the materials, has a small irradiation dose, has a high production efficiency and is beneficial to protecting the environment.

Owner:BEIJING RADIATION APPL RES CENT +1

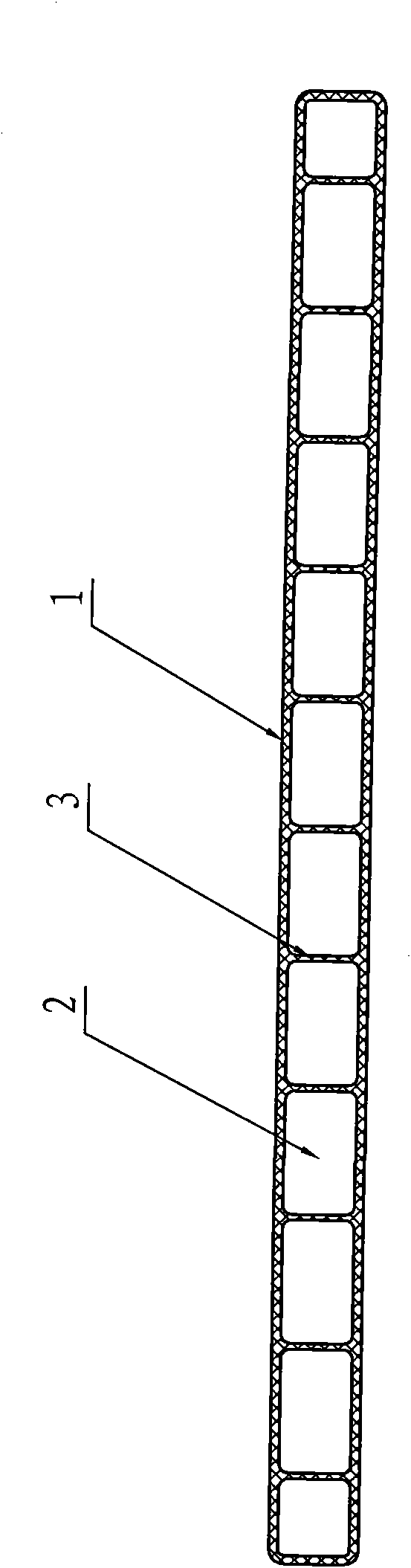

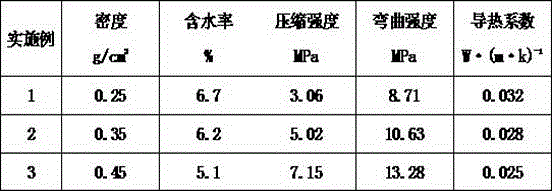

Preparation method of bamboo-wood composite polyurethane foaming material artificial board

ActiveCN106313264ALow densityDimensionally stable structureDomestic articlesFlat articlesWood veneerFoaming agent

The invention discloses a preparation method of a bamboo-wood composite polyurethane foaming material artificial board. The artificial board is prepared from a wood veneer, bamboo filaments, bamboo powder and a polyurethane resin foaming material in a composite mode. A rotary cut veneer or thin plywood is adopted for building a molded framework of an outer layer, and a core layer is prepared from bamboo filaments, bamboo scraps and foaming polyurethane resin in a composite mode. The method comprises the operation steps that a thick veneer or thin plywood obtained through wood rotary cut is selected as a surfaced material at first, and the bamboo scraps and the foaming polyurethane resin are used as core materials, wherein the foaming polyurethane resin is prepared from polyurethane resin, a foaming agent, a catalyst and a stabilizing agent; then, the thick veneer or the thin plywood obtained through wood rotary cut is selected for processing and building the molded framework and placed in mold pressing equipment; the foaming polyurethane resin is mixed to be uniform according to the component matching ratio, the bamboo filaments and the bamboo powder are added, the components are mixed and stirred, and the mixture is quantitatively injected into a molding mold; and finally curing molding, aftertreatment and inspection are carried out for storage. The product prepared through the method has the advantages of being low in density, stable in structural size and good in sound absorption, heat preservation and heat insulation effect, and is the ideal material for building non-bearing components and indoor decoration.

Owner:LONGYAN UNIV

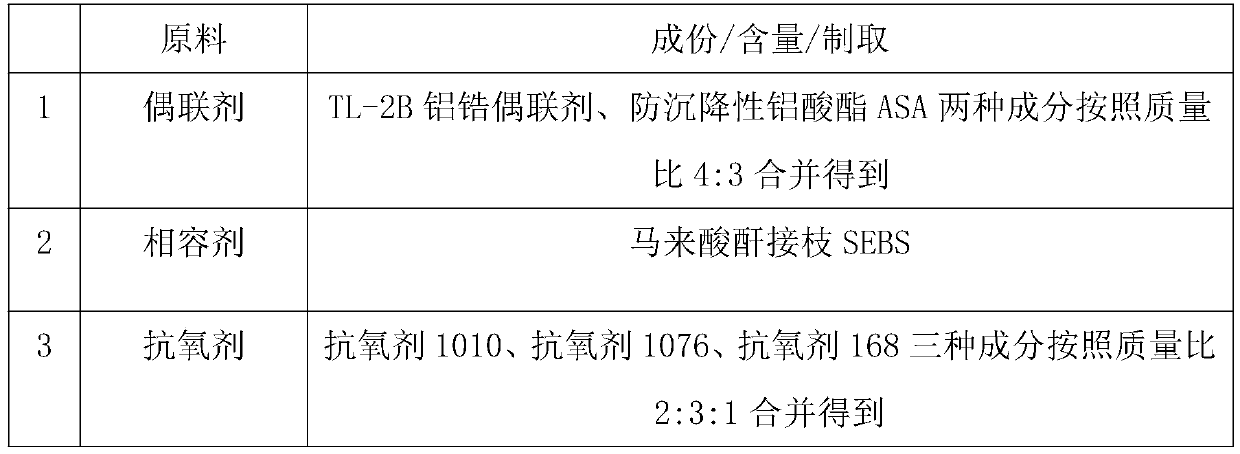

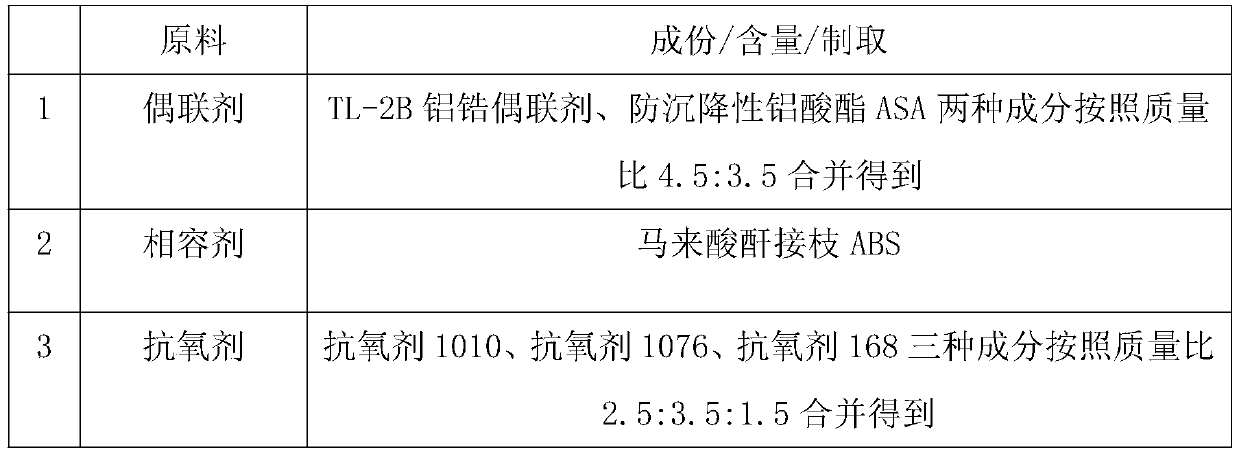

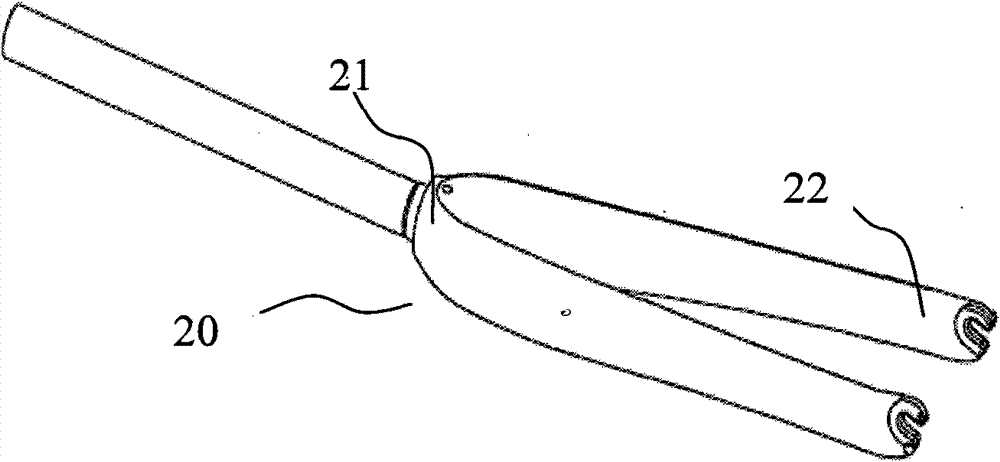

Shielding type FRTP material for wind power generation cover

The invention discloses a shielding type FRTP material for a wind power generation cover, and relates to the technical field of wind power generation cover materials. The FRTP material is prepared from the following raw materials: phenolphthalein side group polyether ketone, bisphenol-A type polysulfone, polyaryl ethynyl, furfural acetone formaldehyde resin, hydrated calcium silicate, Kevlar fibers, moso bamboo fibers, palygorskite powder, cage type polysilsesquioxane, a coupling agent, a compatilizer and an antioxidant. The mechanical properties and environmental adaptability of the FRTP material are greatly improved, the applicability is remarkably improved, the strength, toughness, elasticity, aging resistance, shielding property, and sound insulation property of the FRTP material are all improved unprecedentedly due to the synergistic effect among raw materials, the defects in the prior art are overcome, and the application prospect is wide.

Owner:安徽菲扬新材料有限公司

Glass fiber reinforced polylactic acid composite material, preparation method and applications thereof

The present invention provides a glass fiber reinforced polylactic acid composite material, a preparation method and applications thereof, wherein the glass fiber reinforced polylactic acid composite material comprises, by weight, 20-60 parts of glass fiber, 40-80 parts of polylactic acid, 1.5-5 parts of a silane coupling agent, 1-2 parts of an antioxidant, and 0.1-1 part of a lubricant. According to the present invention, the prepared glass fiber reinforced polylactic acid composite material is biodegradable, has excellent mechanical property and excellent thermal stability, has wide application range, and particularly can replace the traditional metal material and be used as the vehicle member material, wherein the molded vehicle member has characteristics of light weight and good appearance quality, and can well meet the use performance of the vehicle member.

Owner:HEILONGJIANG XINDA ENTERPRISE GRP

Radial tire ring traveler component and preparation technique

The invention discloses a meridian tire wire loop component and the manufacturing process thereof. Rubber base material, an anti-aging system, a reinforcement system, an adhesion system, a vulcanizing system and radio sensitizer are mixed in proportion to make a mixture. The rubber mixture is compounded in a banbury mixer. Glue is applied on a coppered steel wire based on the manufacturing technology of the tire wire loop to make the glue-coated steel wire band for meridian tire. An electron accelerator is used for producing a beam current to irradiate the glue-coated steel wire band of the meridian tire under the effect of a constant tension traction apparatus. The meridian tire wire loop component is vulcanized under the condition of luminous irradiation. After being irradiated, the crude rubber of the meridian tire wire loop component has strong Green strength and stable structural size and performance. Furthermore, steel wire withdrawal force is improved and the adhesive strength of the adhesive layer of a steel wire loop is enhanced, so the quality of a tire is improved. In addition, irradiation dose is small, the manufacturing cycle of products is shortened and production efficiency is high, thus being beneficial to environmental protection.

Owner:BEIJING RADIATION APPL RES CENT +1

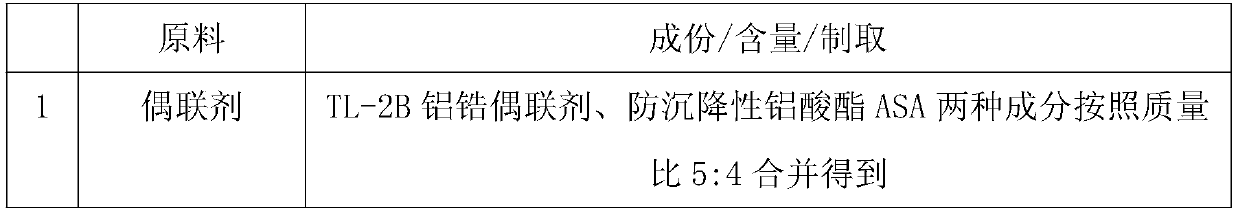

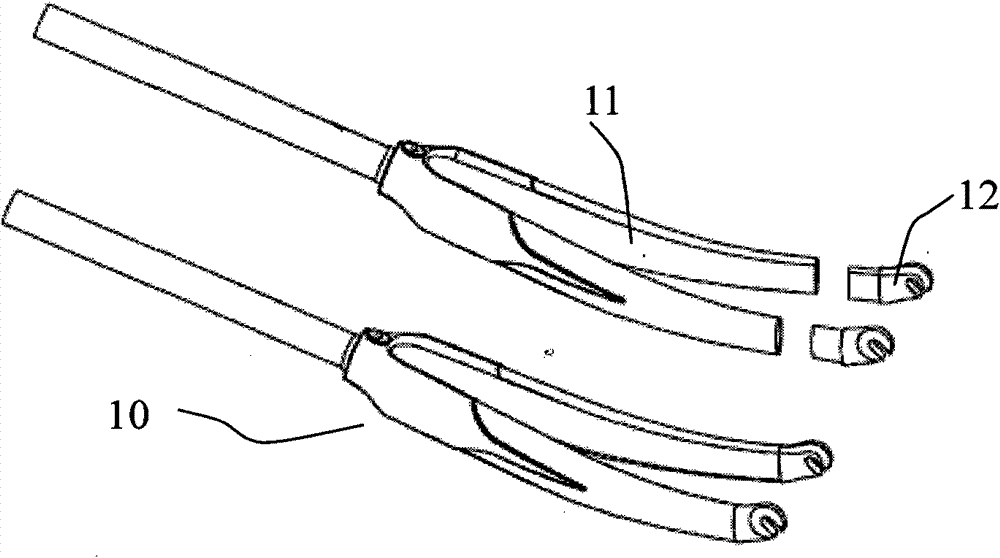

Emulsion liner auxiliary pre-impregnating mould pressing prepared integrated front fork mould and method thereof

The invention discloses an emulsion liner auxiliary pre-impregnating mould pressing prepared integrated front fork mould and a method thereof, which are fit for manufacturing the front fork of a bicycle with compound materials. The method comprises the steps of: preparing two detachable combined two sets of mould devices, wherein the first set of mould device is used for paving a fork bone layer and the second set of mould device is used for paving left and right two hooks, after finishing the paving process, placing an emulsion liner in a fork bone lower mould, simultaneously forming on a machine frame after combining the moulds, and acquiring an integrated front fork product after cooling and de-molding. Compared with a sectional front fork, the integrated front fork has better consecutiveness, requires no serials process like post-gluing process in the manufacturing process of the sectional front fork, overcomes the shortcomings of the sectional front fork that the mechanical property at the joint between the hook and the fork bone is different and the size deviation easily occurs by using the integrated structure, and has excellent size stability and mechanical property.

Owner:上海晋飞碳纤科技股份有限公司 +1

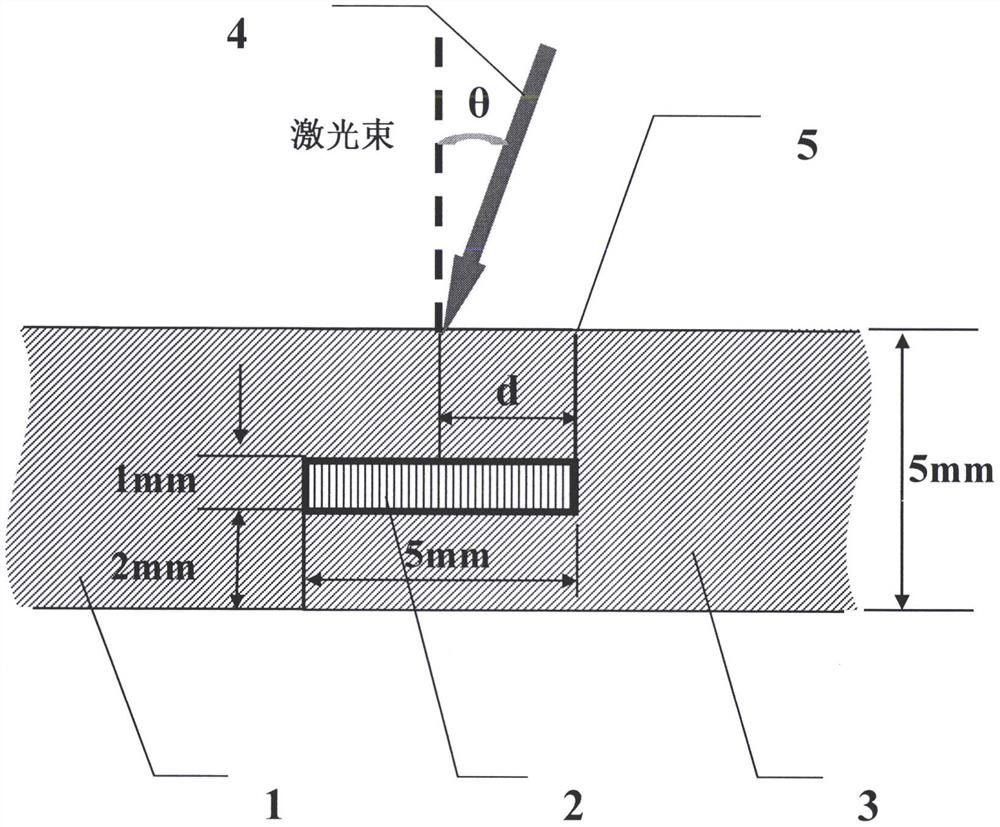

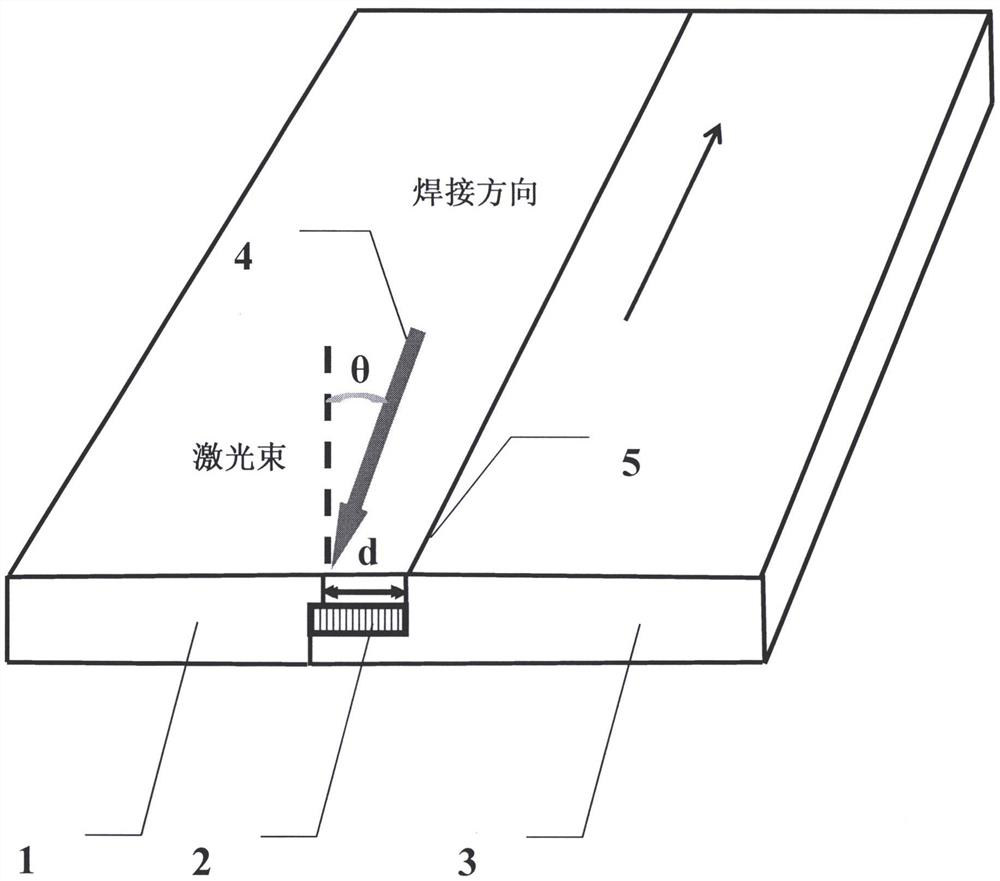

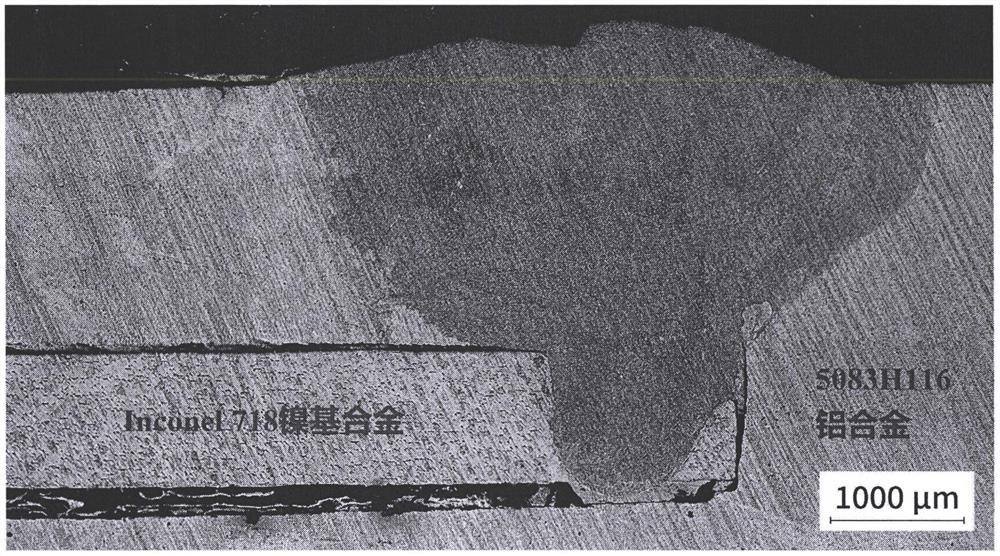

Laser welding method for aluminum alloy/nickel-based alloy or nickel dissimilar material

PendingCN114505577AReduce uneven distributionAvoid brittle fractureLaser beam welding apparatusCrack resistanceAlloy composite

The invention discloses a laser welding method for aluminum alloy / nickel-based alloy or nickel dissimilar materials, and belongs to the technical field of welding. By utilizing a nonlinear energy dissipation composite structure and optimizing process parameters such as laser beam offset, defocusing amount, laser power and welding speed, the interface structure and structure evolution, molten pool metallurgical reaction and phase change process of the aluminum alloy / nickel-based alloy dissimilar material are adjusted through phase change thermodynamics, diffusion dynamics and fluid mechanics; and the geometric dimension, dilution rate and interface concentration gradient of the asymmetric molten pool are controlled, and the harmful non-equilibrium Ni-Al complex phase reaction chromatography phase is limited. And the effective interface connection area is increased, the alpha-Al aluminum-based solid solution and the gamma-Ni nickel-based solid solution with good plasticity are formed, plastic deformation is coordinated, the interface internal stress is relieved, and the welding seam residual stress is reduced. The fine grain strengthening effect of molten pool microalloying on a weld joint and the embrittlement effect caused by a brittle-hard intermetallic compound precipitated phase are mutually counteracted, the crack resistance is improved, the problem of brittle fracture after aluminum alloy / nickel-based alloy welding is solved, and the aluminum alloy / nickel-based alloy composite material is used for aerospace and ship construction.

Owner:ANYANG INST OF TECH

Preparation method of novel environmentally-friendly energy-saving gypsum board

The invention discloses a preparation method of a novel environmentally-friendly energy-saving gypsum board, and relates to the technical field of building gypsum. The method comprises the following steps: 1, subjecting abelmoschus manihot fibers to short cutting and alkali washing; 2, mixing and stirring raw materials; and 3, pouring and forming the mixed and stirred materials; ageing; maintaining, etc. The gypsum board is simple to prepare and outstanding in mechanical strength, hydrophobicity, fireproof performance, heat storing performance and wave absorbing performance; compared with a gypsum board in the prior art, the performance is obviously improved; the application performance is high; the practicability and the reliability are ensured; and the gypsum board is worthy of popularization.

Owner:合肥永泰新型建材有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com