New method for crosslinking tire inner liner rubber material by laser technology

A laser technology and air liner technology, which is applied in the field of cross-linking of the air liner compound, can solve the problems of reduced uniformity of the air liner, waste of raw materials, etc., and achieve the effects of improving strength, reducing pollution and reducing dosage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

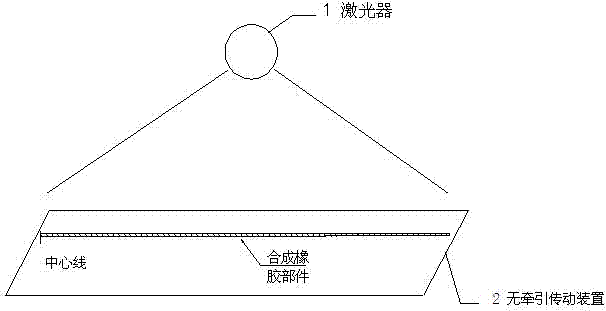

[0013] As shown in Figure 1, the inner liner sheet is fixed on the non-traction transmission device under the laser 1, and the laser scanning process is performed; the laser is a continuous laser with a power of 500-100 watts and a scanning width of 0.2-1.6 m, the transmission speed of the traction device 2 is 0-40m / min, and the processed tire inner liner parts are made into inner liner inner liner parts.

[0014] The principle of the vulcanization and cross-linking pretreatment inner liner inner liner components and the preparation process of the present invention is to realize uniform pre-vulcanization inside or on the surface by adjusting the energy of the laser. The high-energy laser is focused on the inside or surface of the rubber substrate to activate the rubber macromolecules. Active free radicals are generated, and the mutual combination of these free radicals (coupling termination) makes the rubber macromolecules form a C""C bond, cross-linking occurs, and the rubber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com