Lens driving device

A lens driving device and lens technology, applied in the direction of electromechanical devices, installation, electric components, etc., can solve problems affecting electromagnetic induction, etc., and achieve the effects of improved electromagnetic induction force, high assembly quality and assembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

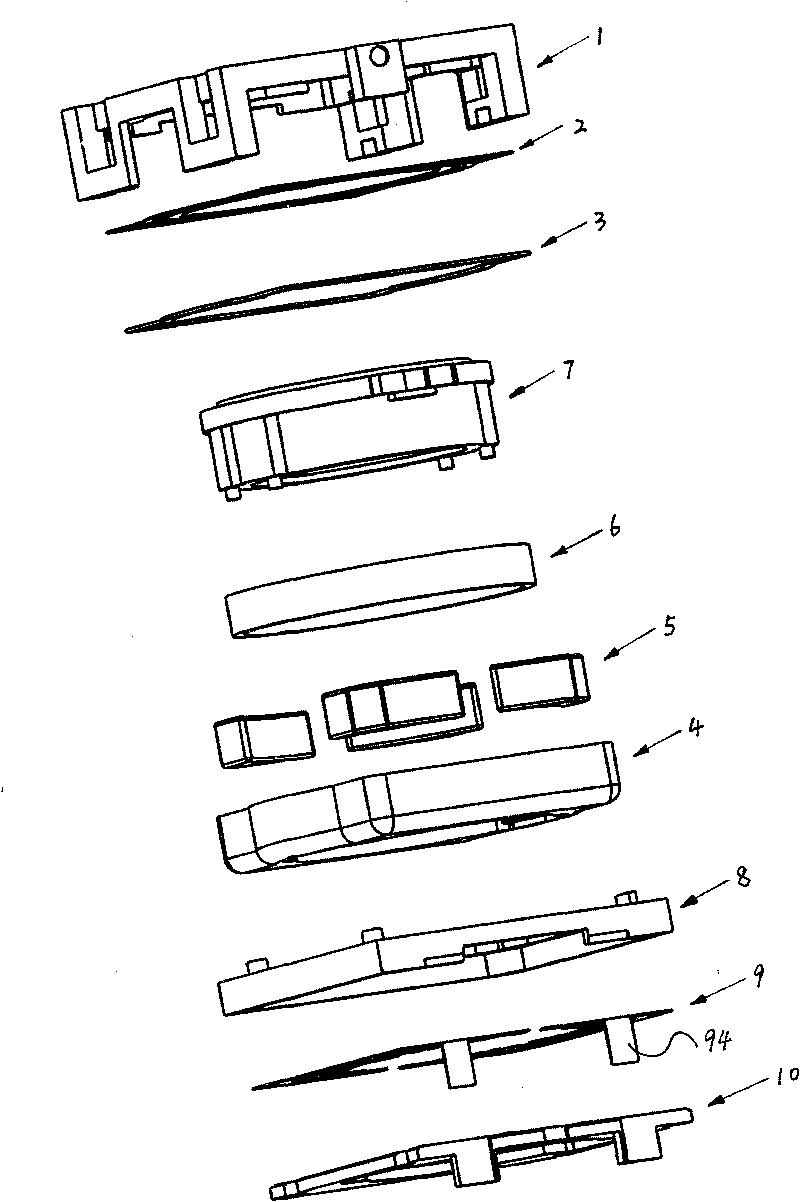

[0024] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

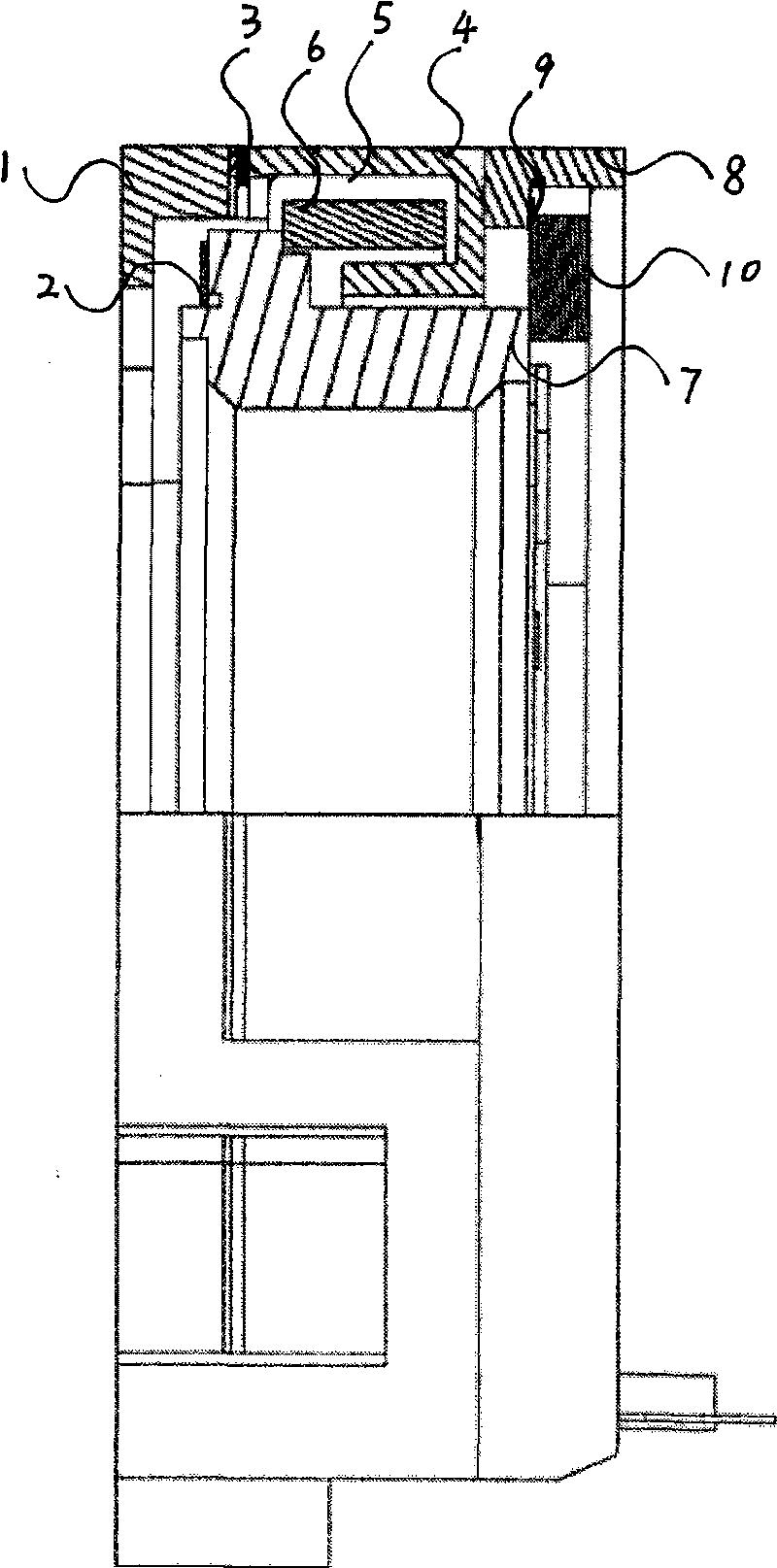

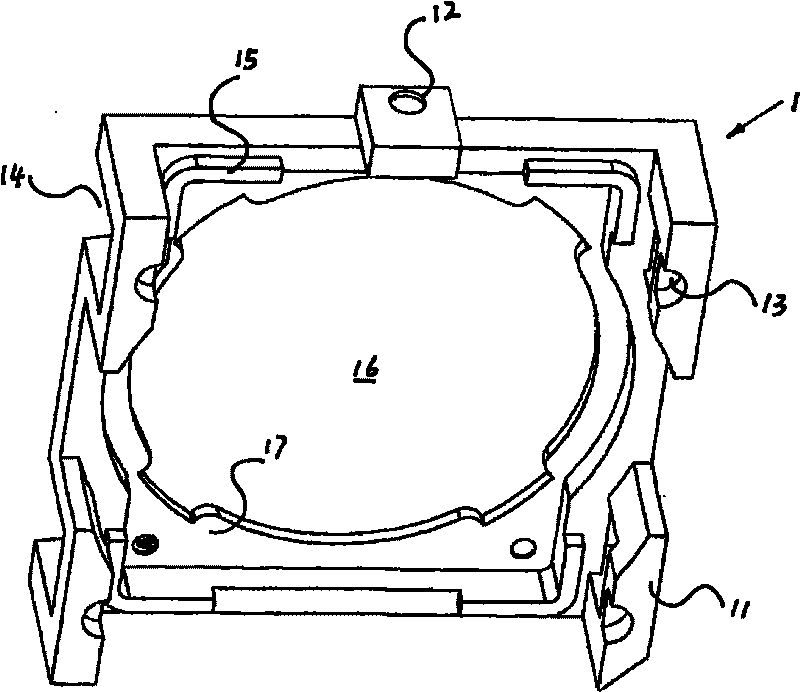

[0025] Such as Figure 1 to Figure 8 An embodiment of the present invention is shown, which includes a front frame 1 and a rear frame 8 corresponding to the front frame 1 . The front frame 1 is provided with a central through hole 16 and an outer projection 12; two clips 11 are symmetrically arranged on the two outer sides of the front frame; There are semicircular positioning holes 13.

[0026] The top of the front frame is provided with a rectangular inner end surface 17 with circular arcs on both sides, and an "L" shaped convex strip 15 is respectively arranged on the four corners of the inner end surface, and the position of the convex strip 15 corresponds to the clip 11 .

[0027] The rear frame 8 is set as a frame structure, and the two sides of the rear frame 8 are respectively provided with two semicircular projections 83, and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com