Emulsion liner auxiliary pre-impregnating mould pressing prepared integrated front fork mould and method thereof

A prepreg and one-piece technology, applied in household appliances, other household appliances, household components, etc., can solve the problems of easy deviation of the hook position, complicated subsequent processing, and low production efficiency, so as to save modification and finishing The tedious process, smooth and smooth structural lines, and the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to make the technical means, creative features, goals and effects of the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

[0021] Preparatory work is carried out before production, including raw material preparation, prepreg preparation, Y-shaped latex liner preparation, mold preparation, mold cleaning, machine preheating, etc. When making, first apply a layer of release agent on the surface of the mold (in this example, Henkel Frekote 55-NC release agent is selected), so as to ensure the smooth release of the product after molding.

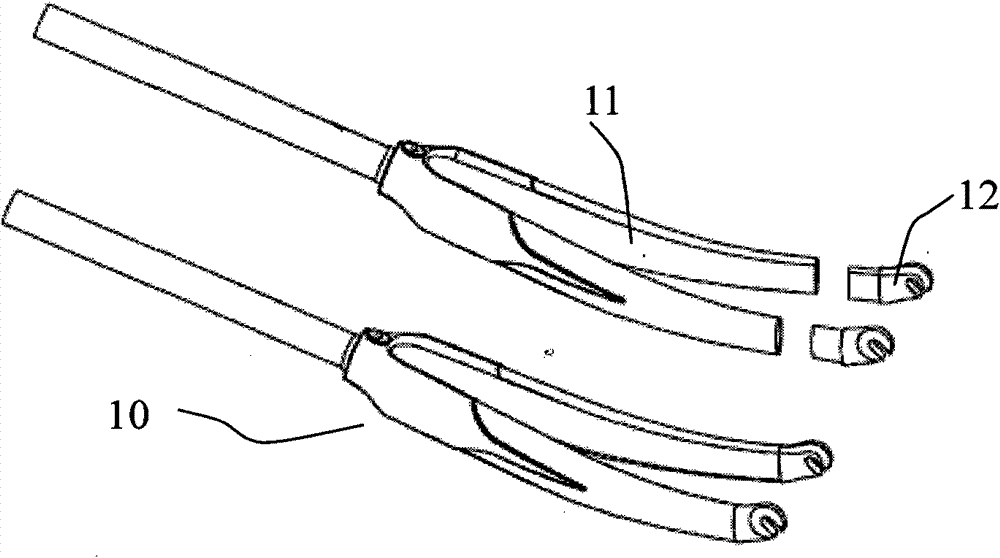

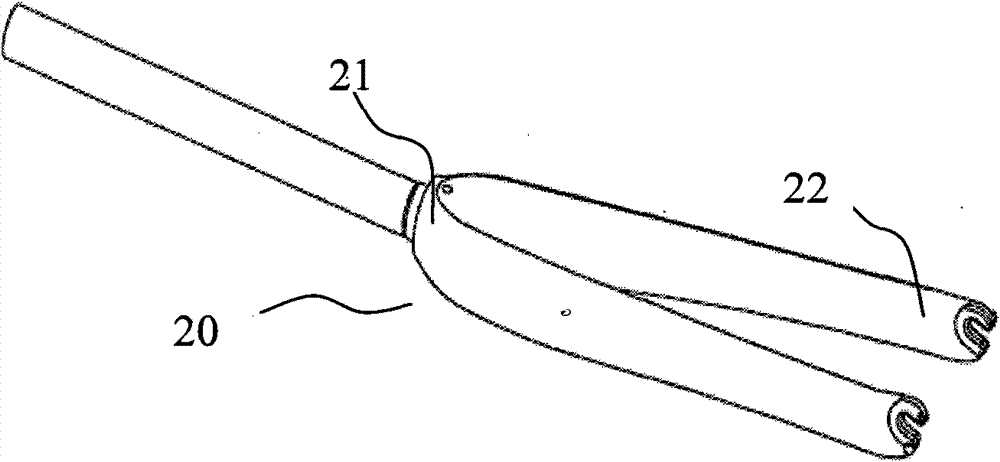

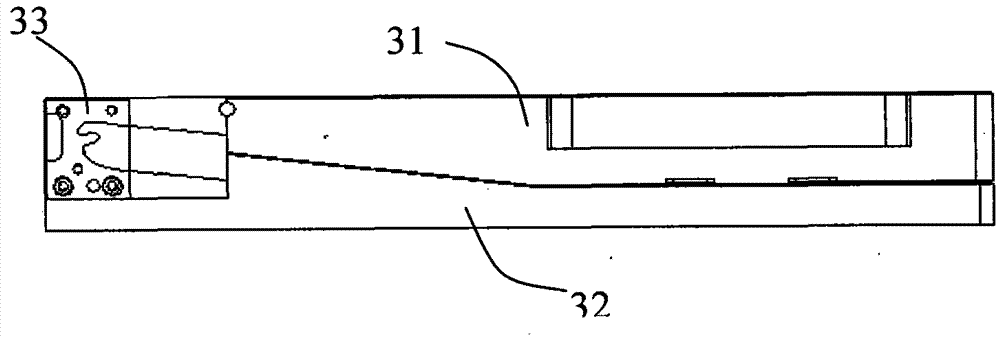

[0022] First, prepreg layup is carried out in wishbone lower mold 32 (using Toray TORAYA prepreg, grade P3252S-12 / 33, which is ±60° two-layer unidirectional fabric), and the layup method is according to the pre-designed layup method. layer structure, because the front fork itself is a special-shaped structure, and its different positions have d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com