Light high-strength flame-retardant weather-resistant continuous fiber reinforced thermoplastic composite plate and preparation method thereof

A technology for reinforcing thermoplastic and continuous fibers, applied in chemical instruments and methods, other household appliances, synthetic resin layered products, etc., can solve the problems of complex process, easy water absorption damage, degumming and delamination, etc. Flame retardant effect, effect of reducing usage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

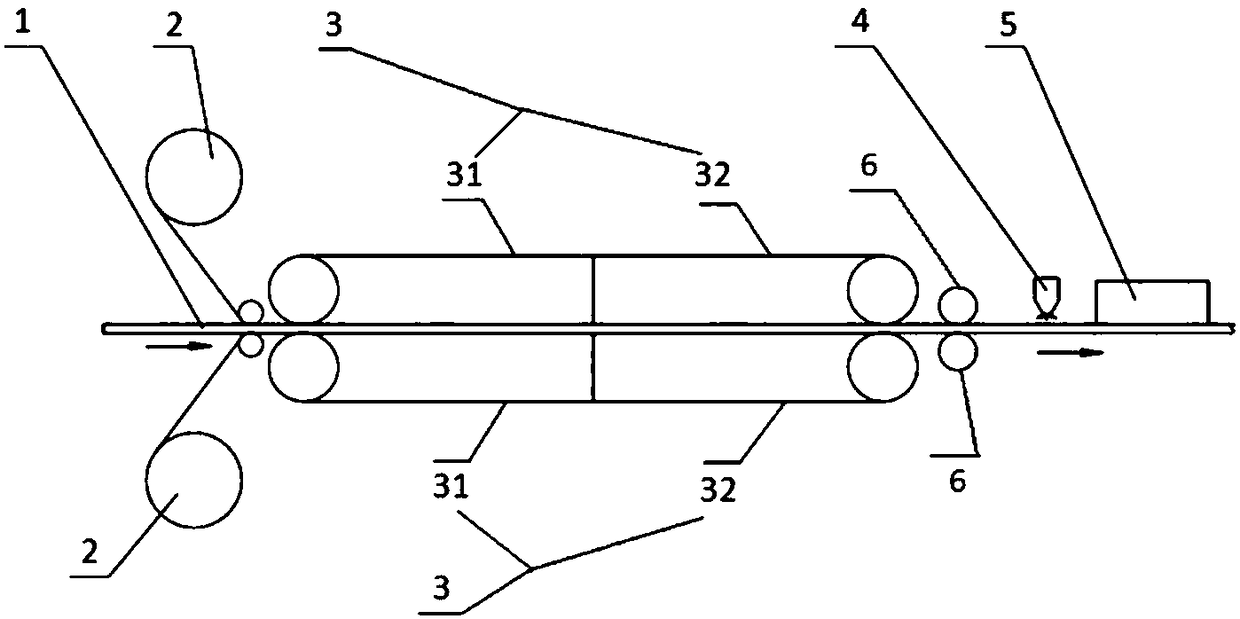

[0061] A method for preparing the above-mentioned lightweight, high-strength, flame-retardant and weather-resistant continuous fiber-reinforced thermoplastic composite sheet, such as figure 1 As shown, it includes the following steps:

[0062] The flame-retardant continuous fiber-reinforced thermoplastic resin prepreg tape roll 2 (as the surface layer) and the flame-retardant continuous fiber-reinforced thermoplastic resin prepreg tape roll 2 (as the bottom layer) are unrolled together, and then combined with the flame-retardant foam material 1 (as the core layer) is put into the heating zone 31 of the double-steel belt press 3, so that the surface layer and the bottom layer are hot-melt composited, thereby performing hot-compression composite molding with the core layer, and then in the cooling zone 32 of the double-steel belt press 3. Cold-press composite molding; followed by traction roller 6 to the spraying equipment 4, online spraying of weather-resistant coatings to form...

Embodiment 1

[0071] The preparation method of the lightweight, high-strength, flame-retardant and weather-resistant continuous fiber-reinforced thermoplastic composite sheet of this embodiment includes the following steps:

[0072] 2 layers of continuous glass fiber reinforced polypropylene (PP) prepreg tape with a thickness of 0.5mm, an oxygen index of 32%, and a continuous fiber content of 50wt% (as a face layer) and 2 layers of a thickness of 0.5mm, an oxygen index 32%, continuous fiber content of 50wt% continuous glass fiber reinforced polypropylene (PP) prepreg rolls (as the bottom layer) unrolled together, and then with a thickness of 30mm, flame retardant grade V0, density 60kg / m 3 The expanded polypropylene (EPP) (as the core layer) is put into the heating zone of the double-steel belt press, and the surface layer and the bottom layer are hot-melt composited in the heating zone, so as to perform thermocompression composite molding with the core layer. The temperature is 140℃, and...

Embodiment 2

[0080] The preparation method of the lightweight, high-strength, flame-retardant and weather-resistant continuous fiber-reinforced thermoplastic composite sheet of this embodiment includes the following steps:

[0081] Three layers of continuous glass fiber-reinforced polyethylene terephthalate (PET) prepreg tape rolls with a thickness of 0.8mm, an oxygen index of 30%, and a continuous fiber content of 70wt% (as the surface layer) and 3 layers A continuous glass fiber reinforced polyethylene terephthalate (PET) prepreg tape roll (as the bottom layer) with a thickness of 0.8mm, an oxygen index of 30%, and a continuous fiber content of 70wt% was unwound together and then re-wrapped with The thickness is 40mm, the flame retardant grade is V0, and the density is 80kg / m 3 The expanded polypropylene (EPP) (as the core layer) is put into the heating zone of the double-steel belt press, and the surface layer and the bottom layer are hot-melt composited in the heating zone, so as to pe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com