A kind of bamboo bundle fiber integrated veneer weaving machine and veneer weaving method thereof

A weaving machine and bamboo beam technology, which is applied in mechanical equipment, sugarcane machining, reed/straw processing, etc., can solve problems such as easy broken needles and threads, low efficiency of whole sheeting, inconvenient adjustment of tightness, etc., and achieve saving Satisfactory material, physical and mechanical properties, convenient carbonization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

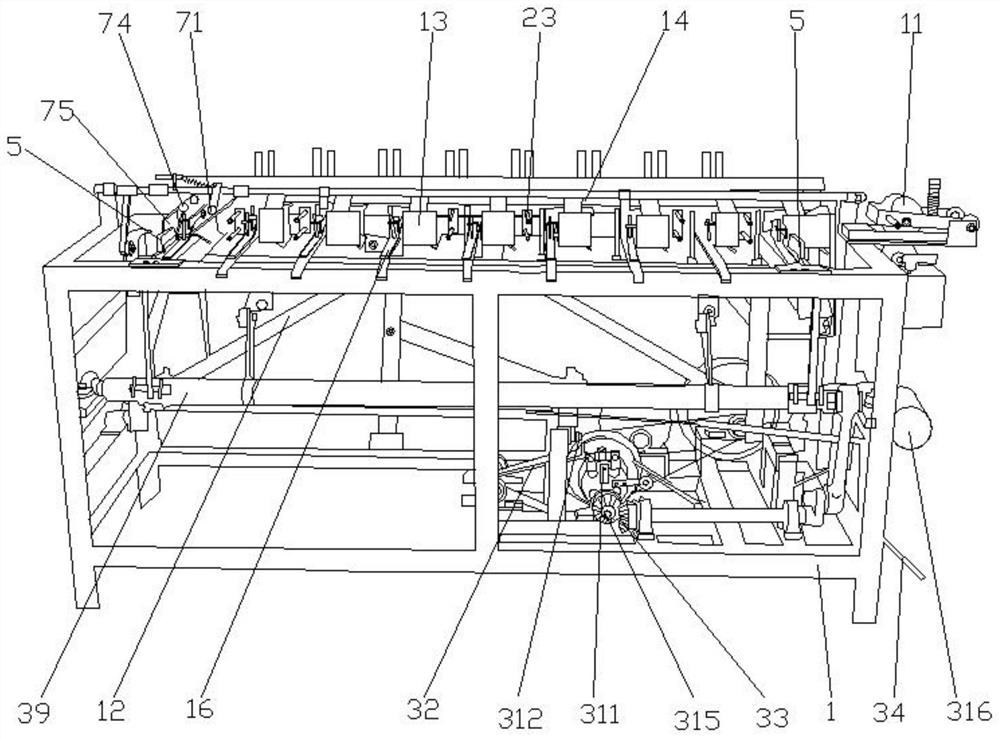

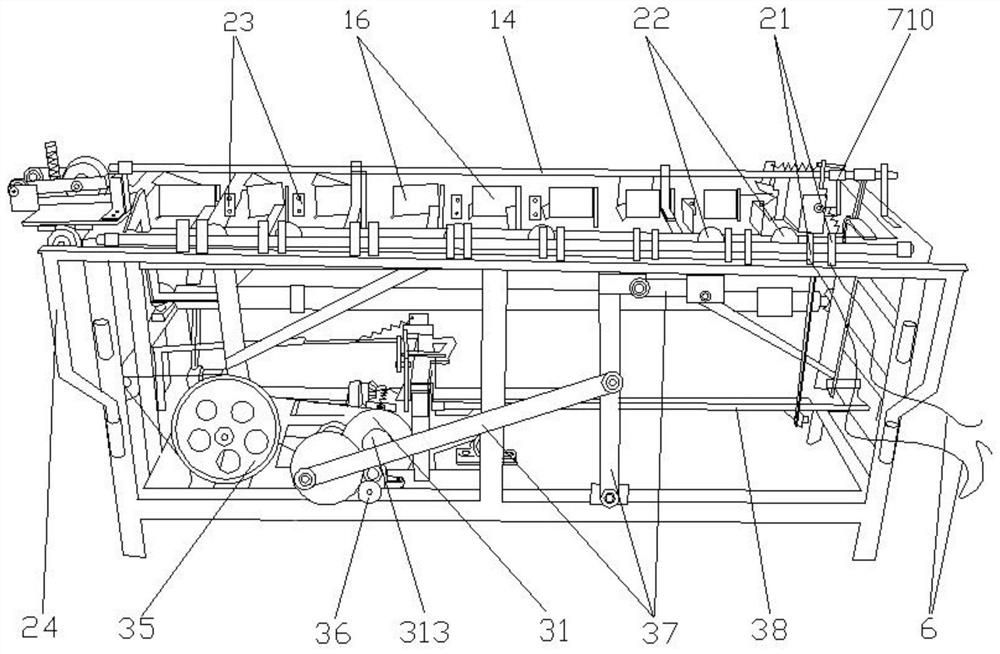

[0036] Example 1, such as Figure 1-4 As shown, the present embodiment provides a kind of technical scheme: a kind of bamboo bundle fiber integrated veneer knitting machine, comprises frame 1, and feed mechanism, weaving mechanism and transmission mechanism are installed on the top of described frame 1, so The feeding mechanism and the weaving mechanism are arranged on the top of the frame 1, the transmission mechanism is installed on the inner side of the transmission mechanism frame 1, and the transmission mechanism drives the feeding mechanism and the weaving mechanism to drive;

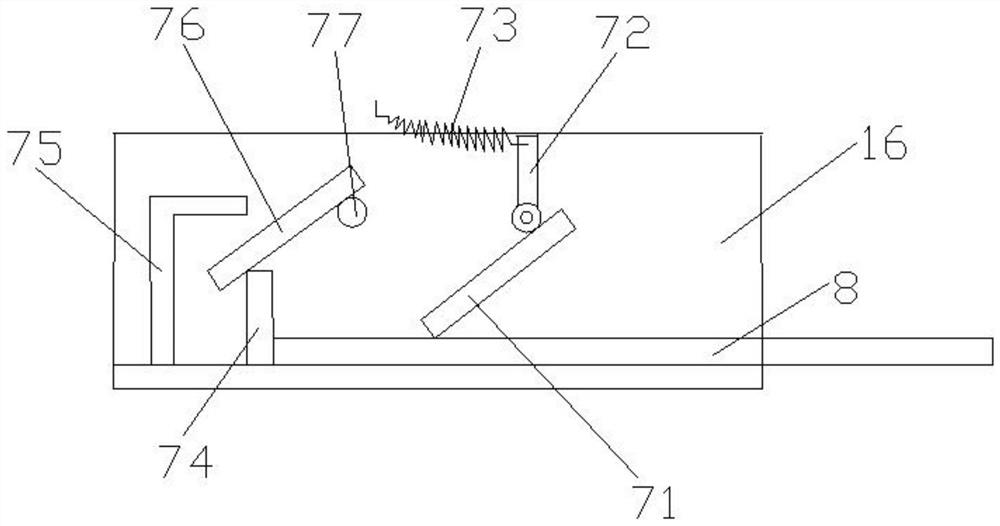

[0037] Described feeding mechanism comprises feeding frame 11, material shifting lever frame 12, hopper flip 13, flip shaft 14 and hopper 16, and described hopper 16 is movably arranged on frame 1, and the quantity of hopper 16 is many One, when the bamboo bundle veneer, described feeding frame 11 is fixed on the top right side of frame 1, and described feeding frame 11 is fixedly installed with f...

Embodiment 2

[0060] The veneer weaving method of a kind of bamboo bundle fiber integrated veneer weaving machine provided by the present embodiment utilizes the veneer weaving machine disclosed in embodiment 1, and the veneer weaving method comprises the following steps:

[0061] S1. Start-up inspection: before starting up, check whether the fasteners everywhere are loose, the tightness of the transmission belt of the clutch 31 and the transmission chain of the transition wheel 35, give the clutch 31, the winding spool 22, the bevel gear 33, the large gear 310, Add lubricating oil to the movable parts of pinion 36, winding connecting rod 37 and clutch pull rod transmission shaft 38, and then let the machine run empty for 2-3 minutes;

[0062] S2. Preparatory work: Put the hot-melt glue sticks at the corresponding positions in the use area of the rack, so that the bamboo veneer presents a dense effect and aesthetics. It is used to restructure the bamboo surface, and arrange 7 hot-melt glue...

Embodiment 3

[0067] A kind of veneer weaving method of bamboo bundle fiber integrated veneer weaving machine, comprises the following steps:

[0068] S1. Start-up inspection: before starting up, check whether the fasteners everywhere are loose, the tightness of the transmission belt of the clutch 31 and the transmission chain of the transition wheel 35, give the clutch 31, the winding spool 22, the bevel gear 33, the large gear 310, Add lubricating oil to the movable parts of pinion 36, winding connecting rod 37 and clutch pull rod transmission shaft 38, and then let the machine run empty for 2-3 minutes;

[0069] S2. Preparatory work: Put the cotton thread sticks in the corresponding position of the rack use area. In order to improve production efficiency and save costs, it is used to reorganize the bamboo core layer. The bamboo bundle veneer is arranged with 4 lines, and the distance between adjacent wiring in the middle is 60cm. The wiring at both ends is 15cm away from the edge of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com