Laser welding method for aluminum alloy/nickel-based alloy or nickel dissimilar material

A technology of nickel-based alloys and dissimilar materials, used in laser welding equipment, welding equipment, metal processing equipment, etc., can solve the problems of easy formation of pores and solidification cracks, low surface tension of liquid metal, and changes in the chemical composition of welds. The microstructure is refined and dense, the effective connection bearing area is large, and the effect of delaying the nucleation and growth of brittle and hard precipitates

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

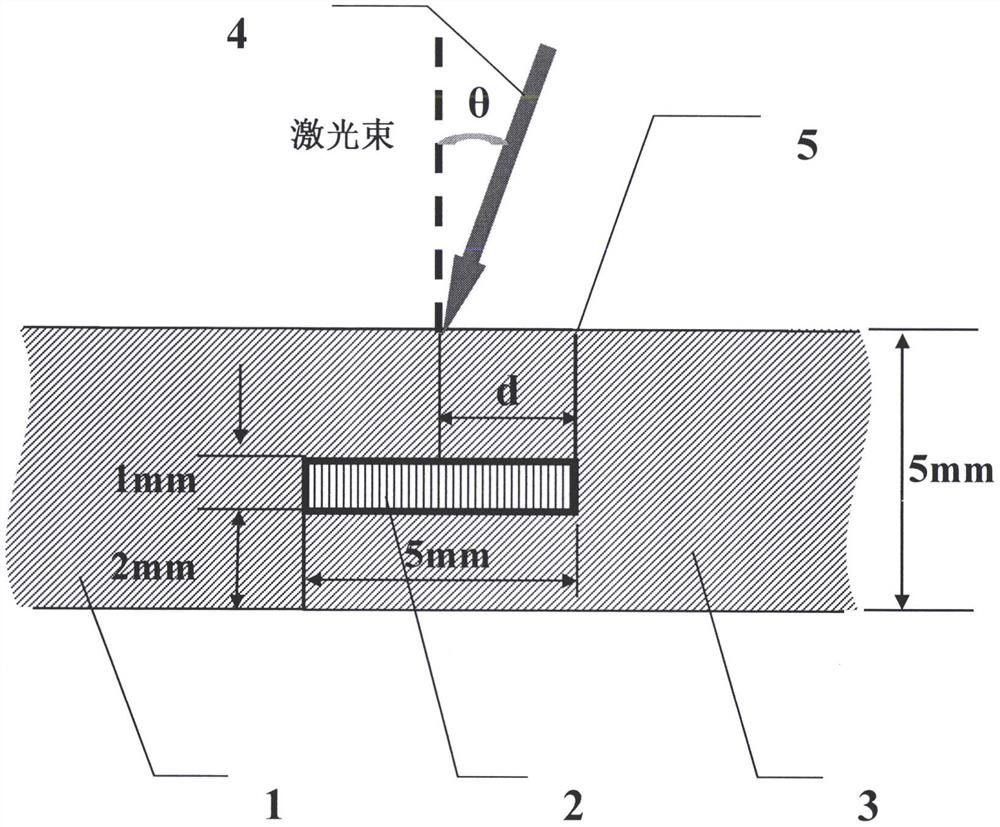

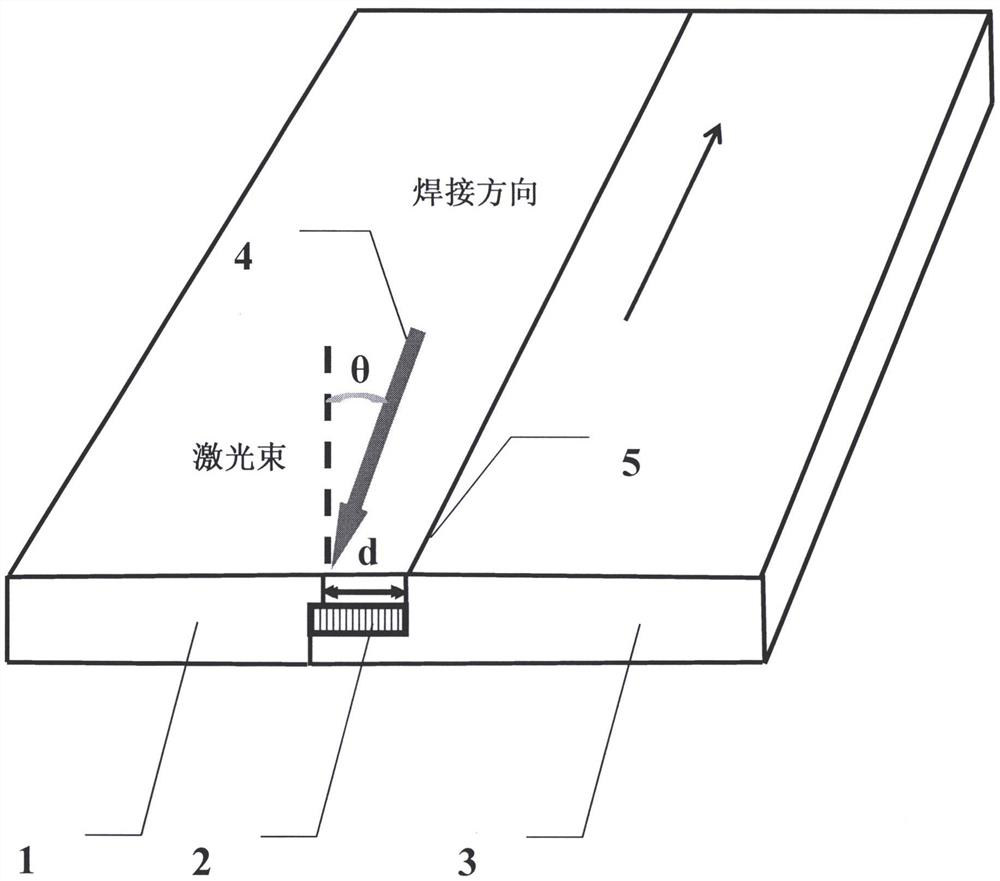

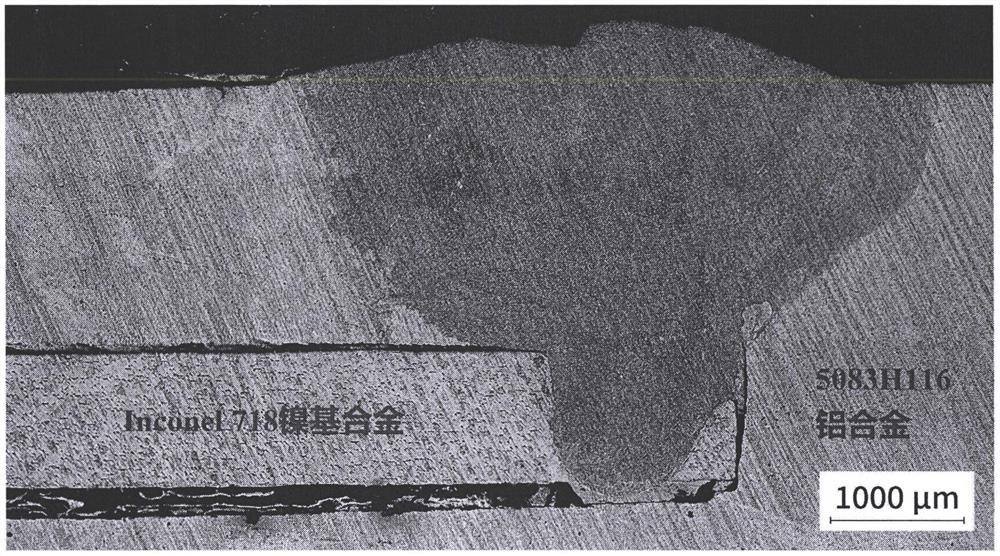

[0028]The method of the invention is used to weld aluminum alloy / nickel-based alloy dissimilar materials, improve weld plasticity from three angles of welding structure, welding process and welding metallurgy, relieve interface internal stress, improve weld surface shape, and improve welding quality. The aluminum alloy material is 5083H116 aluminum alloy, and the nickel-based alloy material is Inconel 718 non-directionally solidified nickel-based superalloy. The chemical composition (mass percentage) of Inconel 718 nickel-based alloy plate is Ni≤52.38%, Cr≤19.3%, Nb+Ta≤5.07%, Mo≤3.12%, Ti≤1.02%, Al≤0.5%, Si≤0.04%, Mn≤0.02%, Cu≤0.02%, C≤0.02%, Fe balance. 5083H116 aluminum alloy plate chemical composition (mass percentage) Mg 4.4%, Mn 0.48%, Fe0.34%, Si 0.138%, Cr 0.065%, Cu 0.037%, Ti 0.029%, Zn 0.012%, Al balance. Inconel718 nickel base alloy sheet thickness is 1mm, width is 5mm, and length is 300mm. The step type 5083H116 aluminum alloy plate is 5mm thick, the bottom side ...

Embodiment 2

[0034] The welding method of this embodiment is different from that of Embodiment 1 in that the offset distance of the laser beam is 0.7 mm, and the other methods are the same as those of Embodiment 1, and the welding of dissimilar materials is completed according to the standard process. There are no obvious defects on the surface of the weld, and there are no pores and cracks inside. In the tensile test, the joint breaks in the upper aluminum alloy weld, and the tensile strength of the joint reaches 67MPa.

Embodiment 3

[0036] The welding method of this embodiment differs from that of Embodiment 1 in that the laser power is 2.2 kW, and the welding speed is 0.4 m / min. The other methods are the same as those of Embodiment 1, and the welding of dissimilar materials is completed according to the standard process. There are no obvious defects on the surface of the weld, and there are no pores and cracks inside. In the tensile test, the joint breaks in the upper aluminum alloy weld, and the tensile strength of the joint reaches 69MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com