Bamboo polyester wool elastic plain weave dyeing process

A bamboo polyester wool and elastic technology, applied in the field of dyeing technology, can solve the problems of uneven dyeing uniformity, slow dyeing speed of wool, lack of hydrophilicity, etc. The effect of dye brilliance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

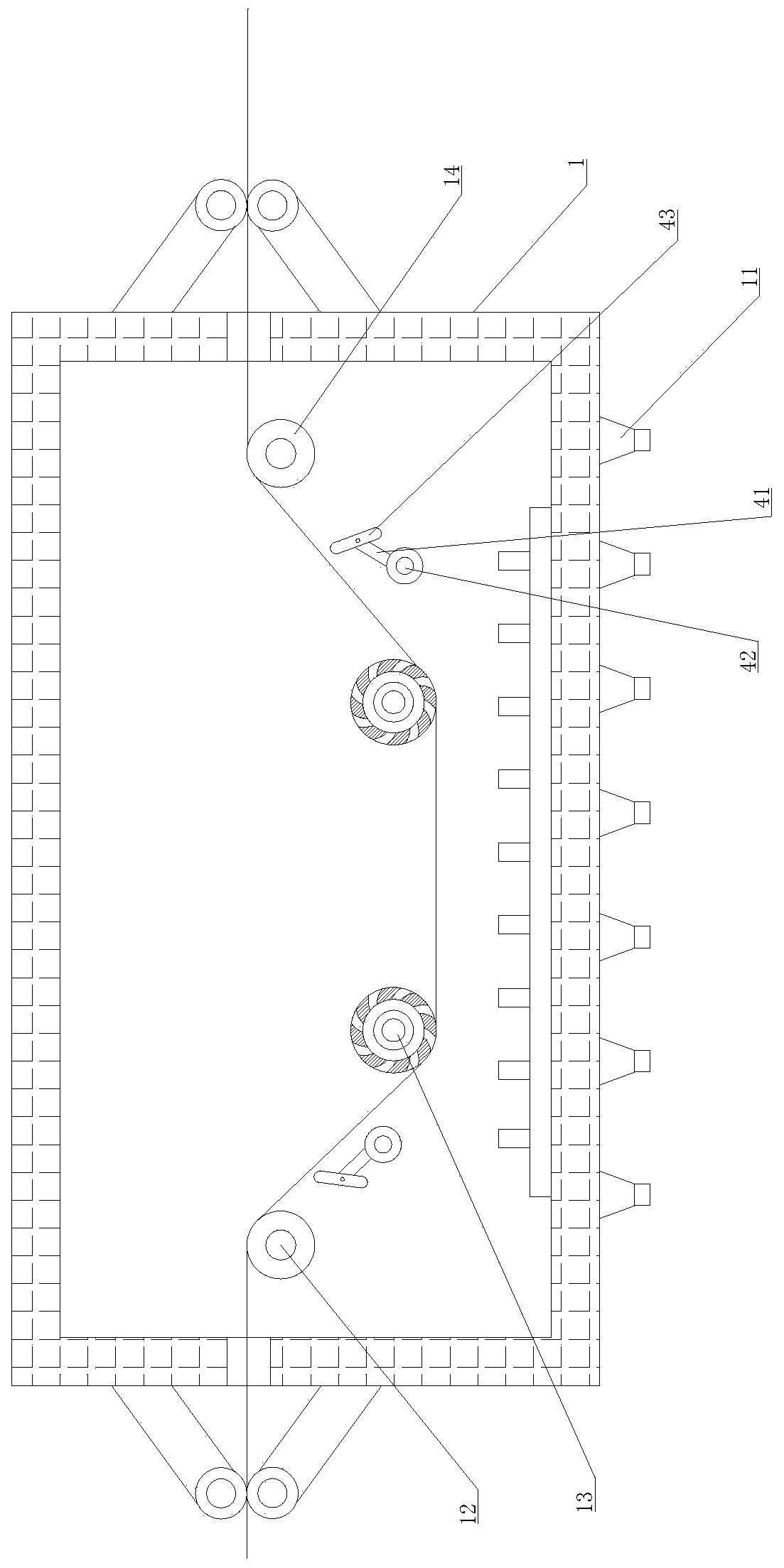

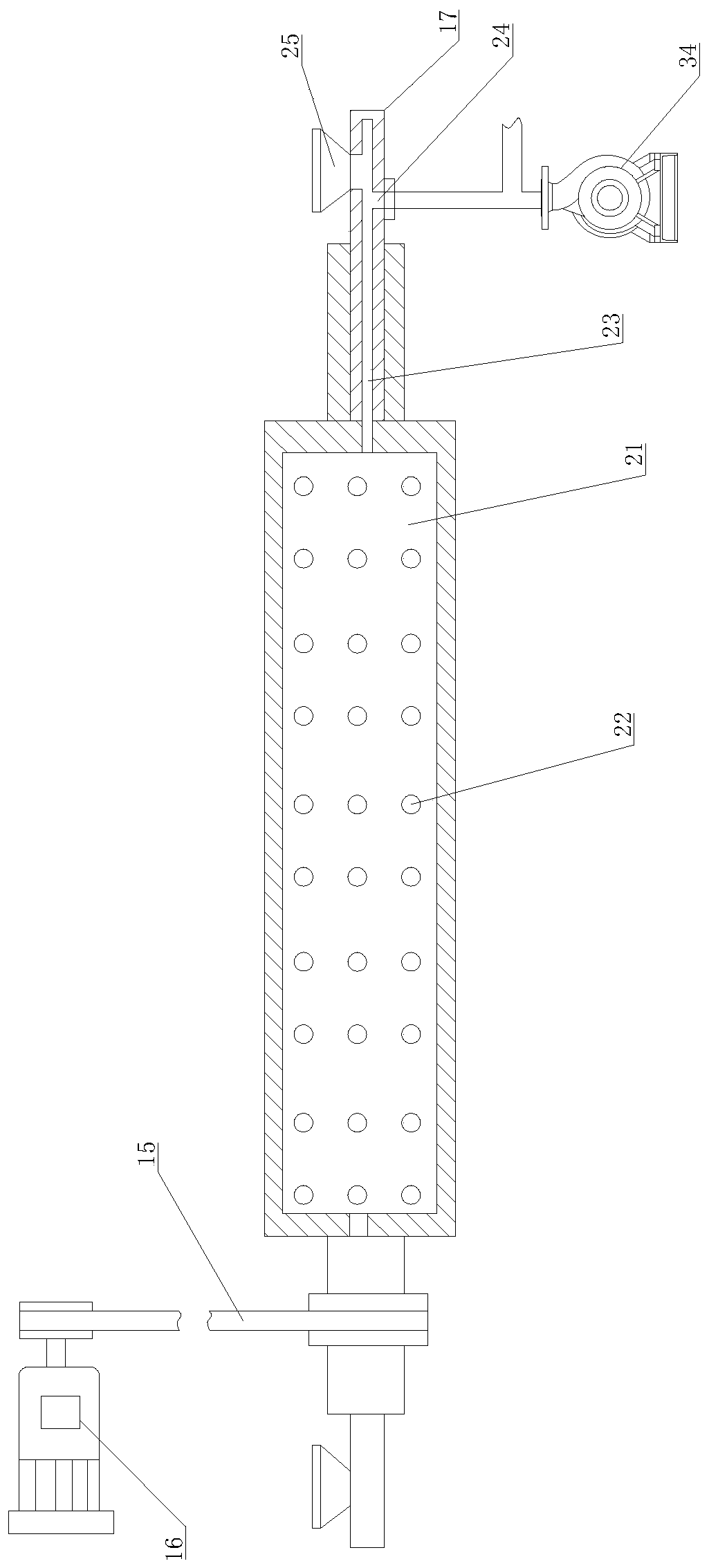

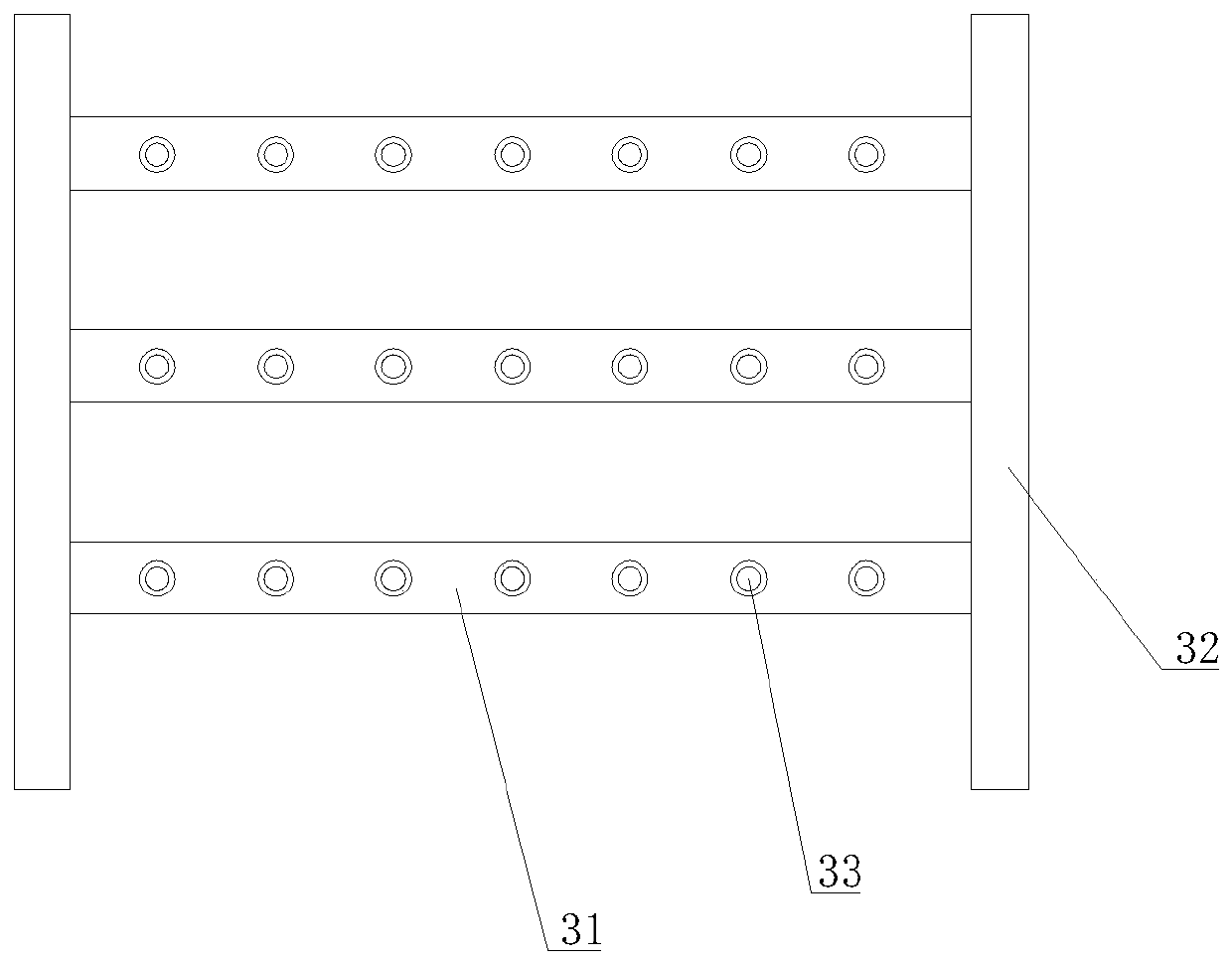

Image

Examples

Embodiment 1

[0030] Bamboo polyester wool elastic plain weave dyeing process comprises the following steps:

[0031]a. Desizing and bleaching the bamboo polyester wool elastic plain weave fabric, soaking the bamboo polyester wool elastic plain weave fabric in 80°C hot water for 30 minutes, rinsing for 10 minutes, and then placing it in a refrigerator with a pH of 6 and a temperature of 90°C Pad in the desizing solution for 30 minutes; then soak the bamboo polyester wool elastic plain weave fabric in hot water at 80°C for 30 minutes, rinse for 10 minutes, and then place it in a bleaching solution with a pH of 7 and a temperature of 80°C for 50 minutes to remove oil stains on the surface of the fabric , hairiness, stabilize the structure size of the fabric, reduce wrinkles, and get A product;

[0032] Bamboo polyester wool elastic plain weave fabric is a plain weave fabric made of bamboo fiber, polyester fiber and wool fiber blended.

[0033] The desizing solution includes 3 g / L of biologic...

Embodiment 2

[0044] Bamboo polyester wool elastic plain weave dyeing process comprises the following steps:

[0045] a. Desizing and bleaching the bamboo polyester wool elastic plain weave fabric, soaking the bamboo polyester wool elastic plain weave fabric in 90°C hot water for 20 minutes, rinsing for 5 minutes, and then placing it in a refrigerator with a pH of 8 and a temperature of 70°C Pad in the desizing solution for 50 minutes; then soak the bamboo polyester wool elastic plain weave fabric in hot water at 90°C for 20 minutes, rinse for 5 minutes, and then place it in a bleaching solution with a pH of 9 and a temperature of 60°C for 30 minutes to remove oil stains on the surface of the fabric , hairiness, stabilize the structure size of the fabric, reduce wrinkles, and get A product;

[0046] Bamboo polyester wool elastic plain weave fabric is a plain weave fabric made of bamboo fiber, polyester fiber and wool fiber blended.

[0047] The desizing solution includes 8 g / L of biologica...

Embodiment 3

[0057] Bamboo polyester wool elastic plain weave dyeing process comprises the following steps:

[0058] a. Desizing and bleaching the bamboo polyester wool elastic plain weave fabric, soaking the bamboo polyester wool elastic plain weave fabric in 85°C hot water for 25 minutes, rinsing for 8 minutes, and then placing it in a refrigerator with a pH of 7 and a temperature of 80°C Pad in the desizing solution for 40 minutes; then soak the bamboo polyester wool elastic plain weave fabric in hot water at 85°C for 25 minutes, rinse for 8 minutes, and then place it in a bleaching solution with a pH of 8 and a temperature of 75°C for 40 minutes to remove oil stains on the surface of the fabric , hairiness, stabilize the structure size of the fabric, reduce wrinkles, and get A product;

[0059] Bamboo polyester wool elastic plain weave fabric is a plain weave fabric made of bamboo fiber, polyester fiber and wool fiber blended.

[0060] The desizing solution includes 5 g / L of biologica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com