Self-cleaning membrane structure and preparation method thereof

A self-cleaning film and self-cleaning technology, which is applied in coatings, fiber types, textiles and papermaking, etc., can solve the problems of film mechanical properties decline, tearing force, and limit the service life of film materials, so as to improve the flame retardant performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

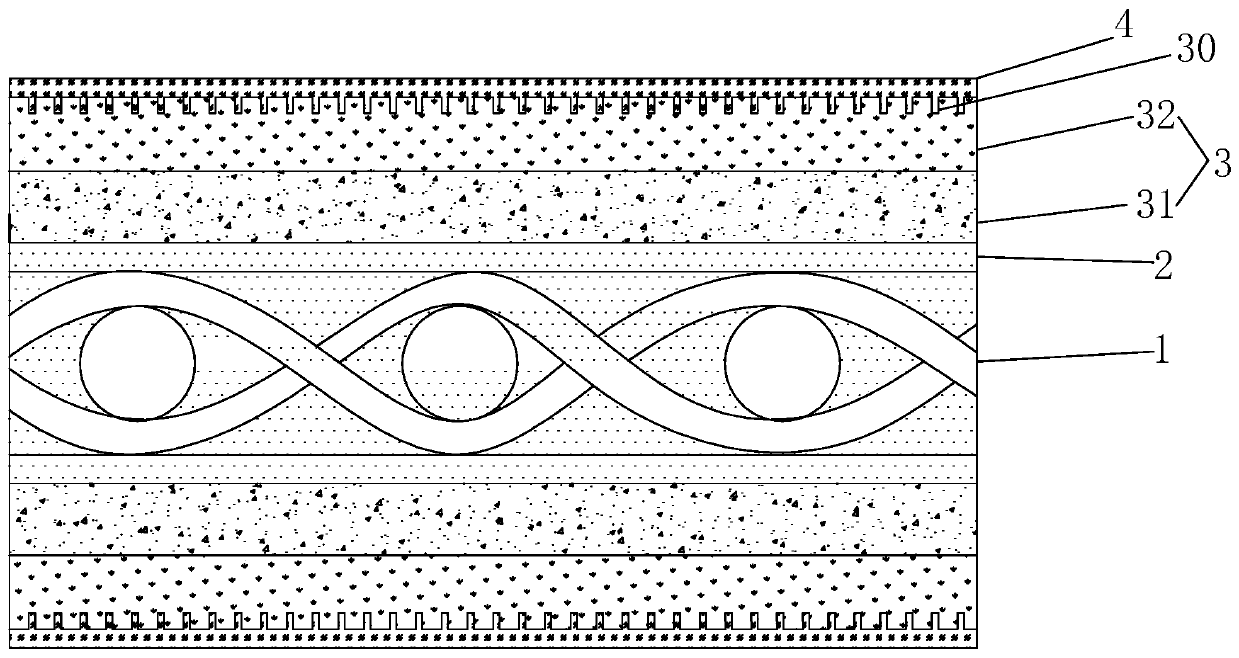

[0079] Embodiment one: refer to figure 1 , is a kind of self-cleaning membrane structure disclosed by the present invention, comprises high-strength polyester cloth core layer 1, preferably polyester woven cloth (weaving silk specification 1100dtex * 1100dtex, weaving density is 9 * 9, base cloth weight 200g / m 2 ), the upper and lower surfaces of the high-strength polyester cloth core layer 1 are pre-dipped to form a reinforcing layer 2; the surface of the reinforcing layer 2 facing away from the high-strength polyester cloth core layer 1 is coated with a PVC functional layer 3; The surface of the polyester cloth core layer 1 is uniformly provided with a plurality of needle grooves 30; the surface of the PVC functional layer 3 facing away from the surface of the high-strength polyester cloth core layer 1 is coated with a self-cleaning layer 4; the PVC functional layer 3 includes a reinforcement layer integrally formed The anti-creep layer 31 of 2 and the anti-aging layer 32 in...

Embodiment 2

[0098] The difference between Example 2 and Example 1 is: Step 1.1: Add 5 kg of viscous polystyrene resin in the preparation of reinforcement layer raw material A.

Embodiment 3

[0100] The difference between Example 3 and Example 1 is: Step 1.1: 15 kg of viscous polystyrene resin is added to the preparation of reinforcement layer raw material A.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com